Beam shaping with diffractive optical elements for bipolar plates

Automotive manufacturers are facing a very fast market transition to electric vehicles. This development demands the integration of new components, while asking for innovative manufacturing technologies.

A key component for electric vehicles is the energy storage—the batteries. They can be fed by an external power supply, or by using a device to generate electric energy. A promising approach to generate the power within the vehicle itself is the use of fuel cell technology. The fuel cell uses hydrogen and oxygen to generate an electric current as well as heat and water as by-products. Each fuel cell consists of several hundreds of bipolar plates that separate the membrane electrode assemblies and include channels for a coolant. The bipolar plate itself is composed of two metallic sheets welded together, each having a thickness of 70 to 100 µm.

The requirements for the welds are evident: cooling channels need to be helium-tight, whereas joints in the flow field need a low electric resistance. In order to join such thin materials with defect-free welds, a very small laser spot is focused on the workpiece by means of a single-mode laser and appropriate welding optics. The right process parameters are well known and constitute no problem for current applications—but have to be significantly modified to suit future needs.

A single bipolar plate can have 1.5 or more meters of laser-welded seams. Assuming 200 bipolar plates in a fuel cell and a production capacity of 1 million fuel cells per year, a single production line has to generate 300.000 km of seam length per year. This number is several magnitudes higher than in conventional laser welding applications of the automotive sector and leads to a major challenge in the fabrication of bipolar plates: to maximize the production capacity by increasing the welding speed and reduce auxiliary process times.

Overcoming welding defects

Remote laser welding is based on mirrors deflecting the laser light at a given angle, using 2D or 3D scanning systems. Process speeds far beyond 100 m/min are possible, but pose a problem for the stability of the welding process: beyond welding speeds greater than 45–50 m/min, the resulting seam includes non-tolerable seam defects, prohibiting the dynamics of scanning optics and available laser power to their full extent. Blackbird Robotersysteme and its sister companies Scanlab and Holo/Or saw this existing shortcoming and made a decision to engineer an adequate solution.

The most severe welding defect, when welding foils at high speeds, is the humping effect. Molten material is ejected towards the rear side of the melt pool where it hits solidified material of the welded seam. Instead of evenly distributing along the surface, the material in liquid phase, will form spherical accumulations due to its own surface tension, causing those distinct humps along the seam. The cause for the missing wetting of the surface is a difference of the temperature between the liquid and the solid base material. Above a certain surface temperature of the base material, the molten material can wet the surface, preventing the occurrence of humps.

The three companies together chose a scientific approach to simulate the occurrence as well as the prevention of humping through a finite element method (FEM), fed by a multitude of parameters: laser power and beam characteristics, workpiece properties, and welding speed and heat conduction properties. First, the formation of humping was validated. Subsequently, a multitude of beam properties were evaluated for the auxiliary heat source at the rear end of the melt pool. Eventually, beam parameters were found that led to a temperature field that completely prohibits the humping effect. Noteworthy parameters were identified as the distance to the primary laser spot and the amount of power needed.

A Holo/Or Flexishaper, developed in 2020, includes a pair of diffractive optical elements (DOEs) generating a central spot and a concentric ring of laser light. By adjusting the relative rotation angle between the two DOEs, the spatial power distribution between core and ring can be freely adjusted (see Fig. 1). Properties such as the ring diameter are predetermined by the design of the DOEs.

The expertise gained from the FEM as well as from a combined integral optical simulation of both scan head and DOE was used to define a process-specified pair of DOEs, hence transferring the process from a simulated environment into a real-world setup. The DOE module is mounted in a 2D intelliSCAN FT scanner with an optical magnification of 1:1.93. An IPG Photonics single-mode laser with a mode diameter of 14 µm is used, resulting in a central laser spot of 27 µm. Stainless steel foils with a thickness of 0.1 mm in a gap-free overlap joint are used as an economic alternative workpiece to bipolar plates.

System trials and results

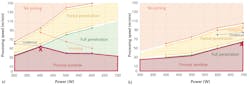

At first, trials were conducted with a usual focal spot by adjusting the relative orientation of the DOEs to send all power to the central spot. These tests were required to identify the key boundaries of the regular process: how do the full penetration, the partial penetration, and occurrence of welding defects vary in function of the applied laser power and processing speed? Figure 2a summarizes the outcomes graphically. Two points are noteworthy: the higher the applied laser power, the lower is the velocity at which the seam defects undercut and humping occur.Subsequently, the optimal process window is determined by a combination of laser power and speed, the latter being the value to be maximized. For the given setup, the optimal speed is found to be 45 m/min at 400 W of laser power. These values correlate well with numbers known from present applications.

The second trial run included the beam shaping in form of an additional ring by adjusting the relative orientation of the DOE plates to each other. The exact same set of trials with combinations of laser power and welding speeds was conducted. Two major impacts can be observed: as expected, the occurrence of humping and undercut defects was shifted to higher welding speeds. In contrast, the penetration depth is reduced compared to a weld without DOEs, at the same laser power and speed. The reason for this is the reduced amount of laser power put into the central spot.

As Figure 2 depicts, a full penetration weld without defects is obtained for 700 W at 60 m/min.

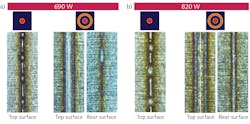

Additional tests were conducted afterwards to prove that at 70 m/min welds no apparent humping can be achieved. Figure 3a shows the initial results for 690 W with and without the use of the DOEs. The standard spot leads to severe humping, whereas the weld with beam shaping leads to a smooth seam surface. A lack of penetration is caused by the missing energy in the central spot. By increasing the power to 820 W, stable welds with full penetration are regained (see Fig. 3b). In total, the welding speed was increased by 55% compared to the maximum speed without beam shaping.The overall higher energy intake by the workpiece leads to a slight enlarging of the weld seam. The standard process shown in Figure 3a has a width of ~60 µm, while the optimized seam has a width of 100 µm. This increase in width is smaller than alternative methods to reduce humping by oscillating the laser beam.

The applicability of a DOE-based beam shaping to improve the high-speed welding of foils for bipolar plates was confirmed in subsequent trial runs on material and workpiece combinations specified by non-disclosed automotive OEMs. Automotive companies as well as their suppliers, system manufacturers, and research institutes need to be prepared for a steep market growth for fuel cell-equipped vehicles. Working towards an early implementation of technologies for the fabrication of bipolar plates is crucial for an initial assessment of technical feasibilities, investments, and scalability.

Beam shaping is a relevant technology to fully deploy all the potentials that a laser-material-interaction offers. The joint research between Blackbird, Scanlab, and Holo/Or demonstrated that a conventional single-mode laser can be used in combination with a process-specific beam shaping and hereby push the process boundaries to higher welding speeds.

Process improvements for bipolar plates are not limited to beam shaping. Future work will cover the implementation of on-the-fly welding and multiple, overlaying scan fields, targeting even higher machine throughputs. Laser welding is a multifaceted technology asking for interdisciplinary teams and continuously progressing research.

About the Author

Thibault Bautze-Scherff

Sales Manager & Member of the Executive Board, Blackbird Robotersysteme

Thibault Bautze-Scherff is sales manager and a member of the Executive Board at Blackbird Robotersysteme (Garching, Germany).

Daniel Reitemeyer

Daniel Reitemeyer is in business development at Scanlab GmbH (Puchheim, Germany).

Natan Kaplan

Natan Kaplan is CTO and R&D manager at Holo/Or (Rehovot, Israel).