Laser beam shaping increases welding speed of thin foils

Fuel cell electric vehicles (FCEVs) made up less than 0.01% of electric vehicles in 2020, but developments primarily in Asia and the United States at the end of June 2021 put more than 40,000 of them on the road globally. Mainly due to government subsidies offered to buyers, more than 8000 FCEVs were sold in the first half of 2021.1 With record-high monthly sales reported in California (759 in March) and Korea (1265 in April), leading fuel cell manufacturers are searching for ways to reduce cost and improve durability—the two most significant challenges to fuel cell commercialization.

Made from several layers of different materials, polymer electrolyte membrane (PEM) fuel cells rely on a membrane electrode assembly (MEA), which includes the membrane, the catalyst layers, and gas diffusion layers. Hardware components used to incorporate an MEA into a fuel cell include gaskets, which provide a seal around the MEA to prevent leakage of gases, as well as bipolar plates, which are used to assemble individual PEM fuel cells into a fuel cell stack and provide channels for the gaseous fuel and air.

Bipolar plates: fuel cell production bottleneck

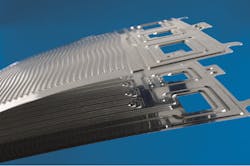

Bipolar plates made of metal provide electrical conduction between cells and add physical strength to the stack. The surfaces of the plates typically contain a flow field, or a set of channels stamped into the plate to allow gases to flow over the MEA. Additional channels inside each plate may be used to circulate a liquid coolant.

Bipolar plate production occurs in three steps. First, rolled sheet metal is either cut or stamped into the proper shape. Next, the flow field is molded. Finally, the two sheets are welded together (see Fig. 1). This last step is problematic in terms of production cost and speed.

“The first two steps take about 100 to 300 milliseconds each. It’s the third step, welding the plates together properly, that requires welding up to 2 meters of metal,” explains Woo-Sik Chung, scientific associate at the Fraunhofer Institute for Laser Technology (Fraunhofer ILT; Aachen, Germany). “Currently, the top possible speed is approximately 0.5 meters per second, which translates into about 4 seconds per weld. That’s 10 times as long as the rest of the process. If each car needs 200 bipolar plates, the welding process would take 800 seconds, or 13 minutes per car, making bipolar plate welding the bottleneck of fuel cell production.”

In terms of cost reduction, the significance of increasing the welding speed of the bipolar plates cannot be overstated since it currently accounts for 28% of the total fuel cell cost.

Increasing speed creates defects

Overcoming the bipolar plate welding bottleneck and associated costs isn’t as simple as increasing the speed of the weld because doing so causes significant defects. While current welding technology has the capacity to go faster, bipolar plates require fully penetrated and narrow seams on 0.1 mm sheets. When the feed rate increases to above 0.7 m/s, the resulting melt stream leads to the humping effect (see Fig. 2).

Because the bipolar plates are stacked together to form the fuel cell, they must be tightly and precisely welded with no defects to function properly and maximize the space allocated to them. A proper bipolar plate weld must pass a hydrogen leakage test, ensuring a tight, leak-free weld. While humping may not only impact the leakage test, it can also prevent the plates from properly fitting in the allotted space.

Because it’s not possible to increase welding speed without causing defects using existing laser welding technology, companies have had to invest in additional capital equipment, establishing multiple laser welding stations for each cut and mold station to avoid a bottleneck, according to Chung. But this solution isn’t optimal because of the added cost of equipment and associated increase in energy consumption.

Dynamic beam shaping lasers

Beyond power, spot size, and feed rate, traditional lasers used for welding offer few other adjustable parameters for process optimization. Since humping occurs when welding bipolar plates at high speeds, feed rates must be constrained to achieve the required weld quality.

While tailoring the laser beam shape for each process can improve results, current beam-shaping solutions such as diffractive optical elements (DOEs) are limited in their ability to be changed on the fly, and mechanical scanners often can’t change fast enough to minimize keyhole instability issues. Most laser beams offer at most a limited selection of preexisting shapes, with no opportunity for flexibility.

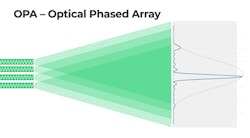

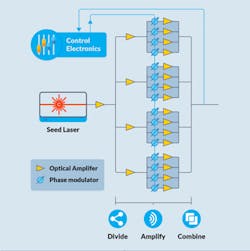

However, recent developments in optical phased array (OPA) technology—a type of coherent beam combining (CBC) that merges many single-mode laser beams into one larger beam—could make hydrogen-powered vehicles commercially viable by increasing welding speed of bipolar plates. With this new laser technology, each laser emits its own light, overlapping with other beams in the far field to create a diffraction pattern(see Fig. 3). This provides the flexibility to easily manipulate the beam shape in real time, without any moving parts, to create a dynamic beam laser (DBL).

By using phase modulators to control individual beams, the resulting interference pattern can be changed to maximize the beam spot position and produce variously shaped patterns inscribed by the beam’s motion—all of which can be done at speeds of up to hundreds of megahertz (see Fig. 4).

With the advent of this dynamic beam-shaping laser, based on OPA fiber lasers capable of delivering up to 100 kW of power, fiber lasers can deliver the control that multimode lasers lack. The latest DBL developments include the ability to control not only beam shape, but also sequence, shape frequency, and focal depth.

Getting over the hump

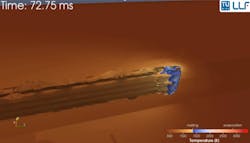

Simulations by Professor Andreas Otto at the Institute for Production Engineering and Photonic Technologies at the Vienna University of Technology (TU Wien) reveal that humping is a complex process. Two things are known. First, humping is a periodic phenomenon (see Fig. 5). Second, when the melt pool is long and the speed is fast, cooling starts from the sides, narrowing the molten channel. As the molten channel narrows, molten material flows up and creates the hump.

With DBLs, the beam shape can be changed to an oval, for example, which concentrates energy input on the sides of the melt pool to maintain channel width in the trailing edge and ensure it stays open. This method offers less resistance, reducing the flow velocity of the melt behind the keyhole and decreasing the risk of humping.

To avoid humping altogether, this method could be combined with the introduction of a different period into the process to interrupt the periodicity of the humping. A beam sequence that switches every 10 µs between the different shapes could eliminate humping and enable welding at higher speeds without causing defects. Another possibility is to use a higher-intensity beam combined with additional laser points at lower intensity to pre- and post-heat the material.

These processes that are now achievable with DBLs will enable an increased feed rate and greatly decrease production time. Civan Lasers (Jerusalem, Israel) is currently working in partnership with Fraunhofer ILT and Smart Move on the Eureka Project to find a solution for welding bipolar plates at high speed.2 The potential solutions described above, which rely on Civan’s technology, will be tested to create a viable, efficient solution for producing bipolar plates at scale.

REFERENCES

1. See www.iea.org/reports/hydrogen.

2. D. Belforte, “Increasing laser welding speed for fuel cell applications,” Laser Focus World (Nov. 12, 2021); https://bit.ly/3GTJLgg.

Eyal Shekel | Founder and CEO, Civan Lasers

Eyal Shekel is the founder and CEO of Civan Advanced Technologies (Civan Lasers; Jerusalem, Israel). Prior to Civan, Shekel founded Al Cielo Ltd., which manufactured fiber-optic gyros and navigation systems; he served as CEO from its inception in 2005 until the company was sold in December 2007.