Blue diode laser revolutionizes copper processing

Lasers have proven themselves repeatedly for welding processes in industrial metal processing. Diode lasers especially impress with their outstanding stability of the melt pool, which leads to better-quality weld seams. However, when processing non-ferrous metals such as gold, copper, and copper alloys, near-infrared (NIR) lasers with wavelengths between 900 and 1100 nm repeatedly reach their limits. The reason is the low absorption rate of NIR radiation in non-ferrous metals. As a result, high energy input is usually required to melt a component. Welding processes therefore often run unstably and result in welding defects, spatter formation, and production scrap.

High reflection complicates copper processing

Infrared lasers are only partially suitable for copper welding because NIR radiation is reflected by copper at room temperature by up to 95%. This means only one-20th of the laser energy input is used for melting, which has an extremely negative effect on the energy and carbon dioxide (CO2) balance of the production process. Copper is becoming increasingly important due to its outstanding electrical conductivity when used, for example, in the production of electric motors in the automotive sector. Therefore, industrial users and laser manufacturers are striving to find new solutions for the laser welding of copper components.

Optimizing production processes

The motivation for a solution led to the development of blue diode lasers with a wavelength of approximately 450 nm at Laserline, a global diode laser specialist. Laser radiation with this wavelength is absorbed by copper at around 60% at room temperature (see Fig. 1).

Therefore, the material can be penetrated by 12X the energy than with a NIR laser—an average absorption rate of around 5%, considering the same output power. As a result, the energy requirements of laser welding are drastically reduced. And almost all machining processes can be implemented with moderate heat input.

In 2019, Laserline launched LDMblue 1000-60, the world’s first blue continuous-wave (CW) diode laser with up to 1 kW output power. As part of the Efficient High Power Laser Beam Sources (EffiLAS) funding program launched by the German Federal Ministry of Education and Research (BMBF), development is being driven forward. Output powers of 1.5 and 2 kW were achieved just one year later. For the first time, the LDMblue industrial lasers enabled controlled heat conduction welding of highly reflective metals such as copper or gold. Seams with a perfect appearance can be realized on copper foils and copper sheets almost independent of the surface finish of the material. This means new and more efficient joining solutions are now available, especially for welding thin copper battery technology for electric vehicles.

Since spring 2022, blue CW diode lasers have been available with an output power of 3 kW, at an average wavelength of 445 nm, a beam quality of 33 mm-mrad, and typical spot sizes of 0.45 to 0.6 mm. A socket efficiency of approximately 25% is currently the highest for a laser in the visible wavelength spectrum. Although this efficiency is slightly lower than the power outlet efficiency of some NIR lasers, it does not affect the overall energy balance of the process. A blue 3 kW diode laser can easily be used for welding processes where a NIR with the same output power would cause difficulties. Since less output power is required than for copper processing with NIR lasers, energy can be saved despite the lower socket efficiency. Process efficiency is the decisive factor in the end. The power class of 3 kW opens up new application possibilities in the welding of copper hairpins as well as in the additive manufacturing of components made of copper powder material.

Hairpin welding of larger surfaces

Welding of smaller copper hairpins was already possible in 2021 using a blue 1.5 kW diode laser. Areas of approximately 5 mm2 could be welded at a speed of < 200 ms, and hairpins of approximately 2.25 mm2 could be welded at a speed of < 65 ms. Very smooth and homogeneous welds were achieved during the welding process without spattering at medium intensity and a spot size of 1 mm.

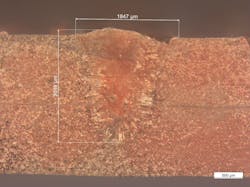

With the 3 kW laser, hairpin welding is now possible without size limitations. Extensive tests prove that diode lasers can weld hairpin twins with sizes of 4, 10, 15, and even 20 mm2 at speeds ranging from 20 to 270 ms (see Fig. 2). Analysis of the cross-section images also showed remarkably low porosity of the seams, promising high conductivity and stability. Even with gaps, rotations, height differences, or lateral displacements, the new 3 kW diode laser provides excellent contacts. Moreover, process optimizations, such as a scanner insert for zigzag or elliptical motion patterns, are not required for uneven pins with 600 µm joining gaps.Welding, cladding, and additive manufacturing

Welding applications such as overlap, fillet, or butt welding can also be reliably implemented in the copper sector with blue 3 kW diode lasers. In overlap welding with 2.9 kW laser power and a speed of 2.4 m/min, a weld penetration depth of 84% is achieved with an area of 1.2 × 1.2 mm (see Fig. 3).With 3 kW of laser power, even more efficient additive manufacturing of large and high-volume copper components will be possible in the future. Components made of two different materials are particularly interesting because copper material is often used to enable efficient cooling in a component, whereas tool steels are built up as the outer shell for rough industrial use. The blue laser can process both materials well, but NIR lasers can only process one. Likewise, significantly higher area rates can be achieved in copper-based deposition welding with blue 3 kW diode lasers.

Simpler processes, better results

The new 3 kW diode laser is not only versatile, but also simplifies production processes. The use of a shielding gas such as argon or helium is not necessary, which reduces production costs. In addition, optical control systems for position determination before the welding process and the associated illumination are no longer required, since blue lasers are capable of welding reliably and safely. If needed, the beam sources can be combined with common systems for process monitoring or an optical coherence tomography (OCT) system (see Fig. 5). For the greatest possible flexibility in the application, individual beam shaping can also be realized.Outlook: Higher laser power and spot-in-spot processes

With highly reflective metals such as gold and copper, blue diode lasers have revolutionized a wide range of new opportunities overall. Increasing the output power to 3 kW opens up additional application options. In joining and cladding processes, much faster welds and higher deposition rates can be achieved. Even larger cross-sections can be handled reliably when deep welding electrical conductors such as copper hairpins. The efficiency of copper plating and additive manufacturing of large copper components also increases significantly.

Reaching the threshold of 3 kW output power certainly does not mark the end of the development of this type of laser. In the future, significantly higher power classes will be achieved. The spot-in-spot technology known as NIR laser welding for bridging wide gaps is currently being tested in conjunction with blue diode lasers.

REFERENCES

1. M. Hummel, C. Schöler, A. Häusler, A. Gillner, and R. Poprawe, J. Adv. Joining Proc., 1, 100012 (2020); https://doi.org/10.1016/j.jajp.2020.100012.

2. E. W. Spisz, A. J. Weigand, R. L. Bowman, and J. R. Jack, NASA Technical Note TN-5353 (1969).

Markus Rütering | Sales Director, Laserline GmbH

Markus Rütering graduated from the University of Applied Sciences in Wedel, Germany, with a major in physical engineering. From 1989 to 2011, he held various positions with laser manufacturer Rofin-Sinar Laser in R&D, sales, product management, and sales management. Since 2011, he has been with Laserline. After he was in charge of all sales in general manufacturing for the Asia-Pacific and Europe-Middle East-Africa territories, he is now sales director and in charge of global sales and marketing.

![FIGURE 1. Absorption of laser radiation in various materials at room temperature [1, 2]. FIGURE 1. Absorption of laser radiation in various materials at room temperature [1, 2].](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2022/08/2209LFW_rut_1.62ec118491eb5.png?auto=format,compress&fit=max&q=45&w=250&width=250)