Many spiders use glue to make their nets sticky, but it tends to dry out and the spiders need to renew it. Some spiders overcome this problem and use a sort of nanotechnology to catch their breakfast. Cribellate spiders have a very specialized silk-spinning organ, the cribellum (Latin for little sieve). From their cribellum they create extra-fine silk fibers, merely tens of nanometers thick. These fibers are so small in diameter that the spider’s victims stick to it by van der Waals forces.

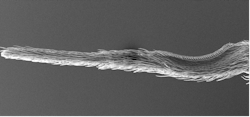

Interestingly, cribellate spiders don’t stick to it. They have a comb-like structure—the calamistrum (Latin for curling iron)—on their hindmost legs that they use to handle the ultra-sticky fiber bundles (see Fig. 1). Why doesn’t the comb-like calamistrum stick to the fibers? Each bristle of the calamistrum is serrated on one side, and scientists discovered that the nanostructures on the bristles keep the nanofibers at distance. In this way, they minimize their contact and reduce the adhesive van der Waals forces between the nanofibers and their legs.1

From spiders to biofilms

These nanostructures don’t stick to very thin fibers, which are actually made to stick on whatever is next to them. Can this idea be transferred to other medical or technical applications? This question is the focus of the European research project Antiadhesive Bionic Combs for Handling of Nanofibers or, briefly, BioCombs4Nanofibers, which is running from 2019 to 2022.

The partners of the project come from Austria (JKU Linz, project coordinator), Germany (BAM, RWTH Aachen University), Greece (FORTH), Romania (INFLPR), and the Czech Republic (ELMARCO). The partner BAM is the German Federal Institute for Materials Research and Testing. To solve the challenges of this interdisciplinary project, experts from JKU Linz and two of BAM’s divisions were involved: 4.1 Biodeterioration and Reference Organisms, and 6.2 Interfacial Processes and Corrosion.

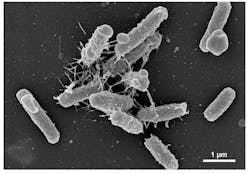

The goal is to find ways the ability to repel thin fibers can be transferred to biomedical applications. The focus is on biofilms, where microorganisms such as bacteria attach to surfaces using very thin biological fibers on their cell surface. Once attached, the microorganisms produce an extra-cellular matrix we refer to as biofilms. Such films are associated with persistent microbial contamination or biofouling. They occur on the human body and lead to chronic infections, which is a reason why any such biofilm within clinical environments must be eliminated. They also develop in wastewater treatment systems and even in simple dishwashers.Nanofibers play an essential role in the spread of biofilms. Figure 2 shows an electron microscopy image of Escherichia coli (E. coli), a well-known bacterium in microbiology. The nanofibers with diameters of 10 to 20 nm visible in Figure 2 are called pili, and are used for motility but also for attachment to neighboring cells and surfaces.

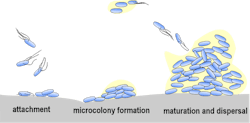

The attachment of biofilms can be seen as a three-step process (see Fig. 3). Single cells attach to the surface, change their gene expression, and then divide and secrete sugars and proteins. They form microcolonies and grow to a mature biofilm, which can detach or expel single cells for further expansion.Repelling biofilms

Biofilms are a common hazard, so many strategies have been developed to defeat them. It seems most desirable to act against their attachment as early as possible, since they have developed resistance to subsequent measures such as antibiotics or UV light. One typical method is to apply specific surface coatings with antibiotics, biocides, or certain ions. They promote contact killing or release toxic compounds into the medium. But such precautions tend to wear out, so other strategies use hydrophobicity or electrochemical modifications, or the trapping of air-bubbles within aqueous media.

The repellent effect of the nanostructures on the spider legs offers a new approach. Suitable nanostructures on a surface could repel the nanofibers from approaching microorganisms and in this way reduce the development of biofilms at a very early stage.

Laser structuring of surfaces

The feature size on repellent surfaces can be derived from investigations of the calamistrum of the spiders: A periodic structure with distances smaller than a micron is needed, which can be created with laser radiation. When linearly polarized laser radiation of sufficient intensity is directed on a surface, a pattern akin to parallel ripples evolves.

Such laser-induced periodic surface structures (LIPSS) appear on almost every material when it is exposed to suitable laser irradiation parameters.2 These ripples form in a self-organized way when using several laser-pulse exposures. The typical feature size is on the order of a few hundred nanometers, with a strong dependence on the polarization direction of the laser light. Generating LIPSS is a single-step approach, which makes it an efficient and relatively simple process also suitable for larger surfaces at industrial scales and processing rates.

Tests show 90% reduction in biofilm formation

For detailed tests,3 the researchers within the BioCombs4Nanofibers project conducted laser structuring experiments on PET polymer foils. They used a krypton fluoride (KrF) excimer laser with a wavelength of 248 nm to create LIPSS with periods ranging from about 200 to 610 nm. The distance (spatial period) between the ripples was varied through a rotation of the PET sample holder controlling the angle of incidence of the laser radiation to the sample surface. Figure 4 shows the result of the structuring where the smallest ripple distance of about 210 nm is achieved with 0° rotation angle of the PET holder. The surfaces were inspected for chemical modifications, and a minor surface oxidization was similar for all irradiation angles.In a subsequent test, genetically modified E. coli without pili were used for identical tests. Without their nanofibers the adhesion on both non-irradiated and laser-irradiated PET foils was much less than in the experiment with regular E. coli. This showed the adhesion of nanofibers is a crucial process for biofilms adherence on surfaces, and it can be reduced through nanostructures.

Dishwashers benefit from spider legs

Certain spiders use extremely fine nanofibers to catch their prey, and to handle these fibers their back legs possess a nanostructure. A European research collaboration tapped this effect to create a surface structure that repels the nanofibers of bacteria—reducing biofilm formation by 90%.

Since they don’t kill the cells, they don’t create any dead cells that can still serve as a basis for subsequent biofilms. This method relies on pure physics, no additional coatings or chemicals are involved, and antimicrobial resistance can be avoided.

This method’s key element is a nanostructured surface. Such a nanostructure can be created on almost any material via laser radiation. Teams involved in the project work on applications for metal surfaces, too. Polymers and plastic materials, stamping, or roll-to-roll methods could prove to be cheaper and faster than direct polymer laser processing.

While this method provides a bacteria-repellent surface, it’s not an antibacterial surface. The latter would require two more orders of reduction. Still, nanostructured surfaces can find applications in food processing or the home appliances industry. For example, laser-processed hierarchical micro-nanostructures were already explored for dishwashers in a previous European project (TresClean). Many industrial environments need clean surfaces and nanoripples can become as important as the hundred times larger hierarchical micro-nanostructures that cause the water- and dirt-repellent self-cleaning effect.

REFERENCES

1. A.-C. Joel et al., ACS Appl. Nano Mater., 3, 4, 3395ff (2020); https://dx.doi.org/10.1021/acsanm.0c00130; also see https://youtu.be/tz7XJkKxgeY.

2. J. Bonse et al., IEEE J. Sel. Top. Quantum Electron., 23, 3, 9000615 (2017); https://doi.org/10.1109/jstqe.2016.2614183.

3. A. M. Richter et al., Nanomater., 11, 3000 (2021); https://doi.org/10.3390/nano11113000.

Andreas Thoss | Contributing Editor, Germany

Andreas Thoss is the Managing Director of THOSS Media (Berlin) and has many years of experience in photonics-related research, publishing, marketing, and public relations. He worked with John Wiley & Sons until 2010, when he founded THOSS Media. In 2012, he founded the scientific journal Advanced Optical Technologies. His university research focused on ultrashort and ultra-intense laser pulses, and he holds several patents.