Ring beams change the game for powder-bed fusion

Additive manufacturing involves a wide variety of techniques, and the materials used are as diverse as the products being generated. Lasers came into play as an additive manufacturing tool due to their excellent steerability and high power, offering the possibility of achieving the productivity required for high-volume manufacturing.

Since its invention in 1996, laser powder bed fusion (L-PBF) has matured to become the leading process in additive manufacturing of metals. The iterative melting of material layers allows for previously inaccessible design freedom. Initially, L-PBF was used for prototyping and development purposes only; today, readily available industrial L-PBF machines process even challenging materials like copper. Serial applications are found in virtually every business field, including medical, aerospace, automotive, and machinery.

While design freedom in additive manufacturing is appealing to the community, the cost and time of producing parts via L-PBF are still considered too high. A reduction by an order of magnitude is typically considered crucial for widespread adoption over traditional process chains.

The laser source plays a key role on this path. Typically, its output power can be temporally adjusted with a high frequency, while its spatial intensity profile is fixed. To achieve productivity gains, the beam profile must be adjusted on-the-fly to match the locally desired structure size.

To create very fine structures (e.g., lattices or thin walls), L-PBF machines use diffraction-limited single-mode lasers with a Gaussian intensity profile. When producing bulk sections, this beam shape imposes severe speed limitations:

- Due to the small beam diameter, the beam must be hatched narrowly to arrive at a dense part, resulting in a low area scan speed.

- The line scan speed is strongly linked to the laser power, which is often limited to a few hundred watts because the high Gaussian peak intensity can cause keyholing. This produces excessive amounts of spatter and soot, resulting in an unstable build process.

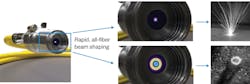

Neither defocusing nor enlarging the beam solves these problems because the Gaussian beam profile is preserved. Ideally, the beam profile is adaptable in its form and diameter, without adding complexity to the delicate free-space optical setup. Initial analysis shows that beams with ring shapes and saddle shapes (i.e., ring beams with some intensity in the center) are best suited to create a uniform transverse temperature distribution within the melted powder (see Fig. 1). So, the ideal L-PBF laser source would provide a single-mode beam for producing fine features and a family of larger beams with ring and saddle shapes for producing larger features.

All-fiber beam shaping

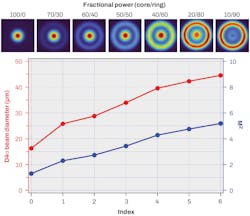

A unique beam shaping technology capable of meeting all of the above requirements is the basis of nLIGHT’s Corona fiber laser family, which includes a L-PBF optimized version called AFX, with a maximum output power of 1.2 kW. The AFX feeding fiber has a single-mode core (14 µm mode-field diameter) surrounded by an annular core (40 µm diameter); the partitioning of the output beam between the single-mode and annular cores can be varied rapidly and reproducibly, which enables the beam profile to be tuned between true single-mode (Gaussian) and a 40 µm ring, with a variety of shapes in between (see Fig. 2). The corresponding beam diameter (second moment, D4σ) ranges from 15 to 45 µm, resulting in a ~10x dynamic range in beam area. All AFX beam shapes can be commanded electrically via the laser communication interface, just as easily as the laser power or modulation rate, with a switching time of less than 25 ms.Accelerated life testing shows no change in performance with >20 million beam changes. The beam never leaves the optical fiber train, which eliminates any contamination or misalignment, before reaching the standard QBH-compatible output connector. AFX provides excellent beam quality for all beam (“Index”) settings, with M2 values between ~1 and 5, resulting in a large depth of focus. For example, with a magnification of 5x (typical for L-PBF tools), the Rayleigh range (ZR) is 3.4 mm for the single-mode setting (Index 0), increasing to 8.1 mm for the largest ring beam (Index 6). Furthermore, AFX beams retain their shapes over a significant distance (~1/2 ZR) on each side of the beam waist. So, AFX provides a large process window for all Index settings.

Increased L-PBF speed and stability

Several L-PBF tool integrators and research laboratories have demonstrated and quantified the advantages of AFX for L-PBF productivity and part quality. Specifically, AFX significantly increases the L-PBF build rate (by up to 7.8x) while simultaneously increasing the process window and maintaining excellent material quality. This unmatched combination of benefits results from AFX’s ability to precisely control heat deposition into the workpiece. In comparison to standard single-mode beams, AFX’s optimized beam profiles dramatically reduce melt-pool instability, reducing generation of soot and spatter that negatively impact material quality and production yields. This benefit, in turn, enables the laser power, scan speed, and L-PBF build rate to be substantially increased. Recent results include:

- Aconity3D showed that AFX can increase the build rate for a titanium alloy by 7.8x, from 5.4 cm3/hr for a standard single-mode fiber laser to 42.1 cm3/hr for AFX. This increase derived from a 4x increase in the melted volume and a nearly 2x increase in the scan rate while maintaining excellent material quality (>99.8% density).1

- Grünewald et al. (2021) at the Technical University of Munich (TUM) showed that AFX can simultaneously increase the build rate (by ~2x) and the process window for L-PBF of stainless steel 316L. AFX enabled use of higher laser power and faster scan speed with a larger process window (i.e., good part quality over a range of powers). Specifically, attempts to increase the power of the single-mode Gaussian beam resulted in undesirable balling or keyholing effects, which limit the L-PBF productivity. In contrast, the AFX power for Index settings of 4 – 6 can be increased without such process instabilities, enabling a higher build rate.2

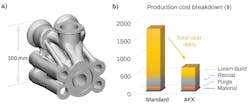

- The Powder Bed Metal group at Fraunhofer IAPT showed a 3x increase in build rate for an aluminum alloy (AlSi10Mg) with outstanding material quality (>99.9% density), while offering a generous process window (see Fig. 3). Further productivity increases are anticipated with additional optimization.3

- Lantzsch et al. (2022) of the Laser Powder Bed Fusion group at Fraunhofer ILT demonstrated that AFX increases the build rate, process window, and material quality for nickel-based alloy 625.4

Local control of material properties

Beyond productivity and cost advantages, AFX has opened a new dimension for L-PBF manufacturing by enabling control of the local microstructure and material properties. AFX’s unique mode profiles provide control of thermal gradients and solidification dynamics within the melt pool, which has been found to determine the material microstructure, offering entirely new design possibilities. Because the AFX beam shape can be changed on-the-fly, the microstructure can be engineered locally, imparting new functionality and optimized properties throughout the part:

- Aconity3D compared the AFX ring-shaped mode profiles with defocused Gaussian (single-mode) beams with similar effective diameters for L-PBF of Inconel 718. They found that the AFX ring beam can increase both the yield strength and the elongation at yield. These key material properties are often anticorrelated, requiring a tradeoff, but AFX has decoupled them. This capability offers the potential for novel component functionality and performance and, in particular, for variable material properties within a single part.5

- The TUM group showed that AFX can control the microstructure and material properties of stainless steel 316L. The different AFX beam shapes enable optimization of the geometry and temperature profile of the melt tracks, thereby controlling the grain growth direction and texture, which in turn determine the material properties. Prof. Wudy, who led this research, observed that with such strategic control of grain growth, “the resulting component properties can be fine-tuned. For example, we can make parts of a component especially stiff or pliable without any additional post-processing. Properties can also be varied within a single component using sophisticated exposure strategies.”6

Shifting the limits in L-PBF

AFX fiber lasers provide significant gains in L-PBF productivity for numerous metals and alloys, fundamentally changing the economics of L-PBF manufactured parts. The key enabler is beam shapes optimized for L-PBF, including true single-mode (14 mm Gaussian), a compact ring (40-mm diameter), and multiple shapes in between, all with excellent beam quality. The beam profile is rapidly tunable directly from the feeding fiber with no free-space optics or other components that degrade performance, stability, or reliability. AFX fiber lasers are available at powers up to 1.2 kW, and the technology is scalable to higher powers and other beam shapes.

While the results presented here were achieved in AFX single-laser setups, the benefits also apply in multi-laser configurations (e.g., dual, quad, octa, etc.). This approach allows scaling the productivity of the latest multi-laser L-PBF machines to even higher records. AFX is enabling a new generation of high-productivity L-PBF tools, paving the way for L-PBF to become the dominant metal additive manufacturing technology for series production. Moreover, AFX’s unique ability to control the local microstructure and material properties offers the potential to fabricate parts with material characteristics, functionality, and performance unattainable with previous manufacturing technologies.

REFERENCES

1. See https://youtu.be/TsumIEibbk8 (see results at time 49:45).

2. J. Grünewald, F. Gehringer, M. Schmöller, and K. Wudy, Metals, 11, 12, 1989 (2021); https://doi.org/10.3390/met11121989.

3. See https://youtu.be/bvqBRtGxwCY.

4. See https://youtu.be/OVemoWOtu5w.

5. See https://youtu.be/OjUj23tH4fg.

6. See https://youtu.be/wbMEf1i28Ko.

About the Author

Andreas Rudolf

Additive Manufacturing Market Development Manager, nLIGHT

Andreas Rudolf is additive manufacturing market development manager at nLIGHT (Camas, WA).

Dahv Kliner

Vice President of Fiber Laser Technology, nLIGHT

Dahv Kliner is vice president of fiber laser technology at nLIGHT (Vancouver, WA).