Commercial aviation, military aviation, drones/unmanned aerial vehicles (UAVs), satellites, and space exploration all fall under the umbrella of aerospace. During the pandemic, commercial aviation projects declined, while space exploration activities continued unabated.

Right now, we are in the midst of a new and exciting global space race, seeing an unprecedented amount of “new space” companies. They tend to be startups, with a mixture of experiences from traditional aerospace, software, automation, and robotics.

These companies are often less entrenched in traditional manufacturing processes and are not tied to one technology or another. Instead, they do what makes sense to achieve their goals. In this current era of the new space race, many launch providers are trying to achieve space flight using smaller, more nimble launch vehicles.

Among the many laser-based technologies available, laser additive manufacturing (AM), or 3D printing, is an ideal option for companies who want a manufacturing process to quickly design, build, and iterate to make structures and vehicles for space flight. AM is fast, nimble, and allows users to pivot quickly. Moreover, many of these new and smaller companies have limited resources and space for capex and tooling costs, which makes laser AM, with its smaller overall footprint for manufacturing, an ideal technology.

In traditional manufacturing, rocketships for space exploration use established and well-known manufacturing processes. For example, using friction stir welding of aluminum sheet metal after bump-forming and shearing to produce barrels, machining pockets out of thick plate for iso-grids, and welding and hot-spin-forming to create domes. All of these processes have an associated lead time for raw materials, processing, cleaning, and inspection. Any reduction in lead time, for any or all of these processes, not only results in decreased overall lead time, but allows extra time for any proof testing, hot fire testing, and vehicle integration.

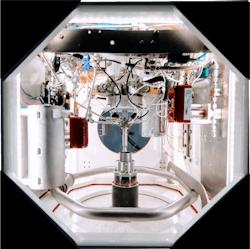

Laser AM can be used to produce space exploration components, including propulsion devices and structural components. For propulsion, specifically rocket engines, the advantages of using laser AM are obvious: the reduction in overall number of parts in an engine (reduces risk of manufacturing flaws when only dealing with tens of parts compared to hundreds of parts), design simplification, and the ability to print cooling channels with unique overhanging angles and improved thrust (see Fig. 1).

With materials that are designed specifically for AM, better heat capacity and strength can be obtained, resulting in improved engine efficiency. Improved engine efficiency can translate into achieving higher orbit or being able to transport larger payloads. For structural components, including the tanks and barrel sections of rocket vehicles, the ability to use laser AM eliminates the cost of required tooling for sheet metal forming and fixturing for friction stir welding, which can run into the $2 million range. Laser AM essentially opens up more flight windows and greater access to space.

Green lasers

One particular innovation in laser AM is the deployment of green lasers. Using a wavelength in the visible spectrum of 515 nm (as opposed to infrared [IR] at 1063 nm), enables laser AM of highly reflective materials such as copper, aluminum, gold, silver, platinum, and iridium to be more effective and efficient. Used in combination with these reflective materials, IR lasers have a hard time coupling the beam to the metal and can result in reflective losses.

Green laser technology, developed on the traditional laser cutting and welding side, when applied to 3D printing makes sense in terms of achieving results with better density, lower porosity, better surface finish, less spatter, and improved productivity (depending on the part and parameters used)—up to 10x faster than IR laser sources with pure copper powder.

Rocket engines printed in copper alloys such as C18150 and GR Cop 42 or 84 follow that better productivity and a faster print speed with fewer defects would give us another channel to access space faster. Combining a green laser metal fusion-printed part in a copper alloy—for example, with a laser metal deposition-printed part in a nickel-based superalloy with an IR laser source—could create a component that is truly a hybrid in terms of dissimilar material and dissimilar process (see Fig. 2).Laser welding of thick section metallics, such as steel, for structural components or heavy-lift vehicles is another way to exploit the useful nature of laser technology. Laser welding is already well established in sheet metal and thicker material. The critical nature of this joining process is clear: to minimize defects and obtain high-quality, reproducible welds. One could even imagine repair welding of components that never leave the ground, such as a strongback on the launch pad.

Another exciting area of potential for laser AM in aerospace is the development of niobium alloys, specifically C103. Nb-10Hf-1Ti or C103 is a refractory material developed for use in afterburners and as nozzle skirts on second-stage vacuum engines in space, and with its high temperature resistance (up to 2500°F) in a vacuum, it has a healthy usage with a common design across various rocket vehicles in sheet metal form. But the lead time for sheet product is very long (>30 weeks), so it bears consideration that if the powder metal was more readily available, laser 3D printing by powder bed processing would be a good option for thrusters and small nozzles that can fit into a standard build envelope. And if more users were able to successfully print C103 on a large-scale platform, such as laser directed energy deposition (DED) or laser metal deposition (LMD) for nozzle skirts more than 1 m long, that would be a game-changer. More work is needed in this area to make this a viable process.

3D-printed parts on Mars

The Mars rover Perseverance has 11 components produced by laser AM. Astronauts have already successfully printed polymer and ceramic parts on the International Space Station (ISS), where the feedstock is less volatile than metal powder and fines can be pyrophoric. The goal of 3D printing on another planet is within reach.

On Earth, we have been able to print low-cost housing with ceramics, so this will very likely translate to the next logical step: printing regoliths on other planetary bodies such as the moon or Mars. It will be easier to print extraterrestrially using native feedstock than dealing with storage and handling of material feedstock during launch, flight, and landing. The Mars rover also had its name plate laser-marked, which is very useful in case of identification.

The overall reduction in lead time gained by using laser technologies in manufacturing processes results in a greater number of flight windows for the final vehicle. For critical components such as grid fins, AM processes are faster and more sustainable than machining out of a block of metal (see Fig. 3).The increased availability of flight windows, higher orbits, and larger payloads open up more opportunities for customers to go into space, whether for space tourism or satellite customers. It is an exciting time to be involved in space exploration, and laser technology is the perfect tool to achieve these lofty goals. Keep watching the skies!

About the Author

Eliana Fu

Industry Manager of Aerospace and Medical, Trumpf Laser Technology Center

Eliana Fu, Ph.D., is industry manager of aerospace and medical at the Trumpf Laser Technology Center (Plymouth, MI). She was educated at Imperial College, University of London with a master’s degree and PhD in materials science. She also performed postdoctoral research at Loughborough University (UK) and Clemson University (USA). After working extensively in the traditional manufacturing world, with TWI then TIMET and SpaceX, she turned her attention to additive manufacturing at SpaceX and then with Relativity Space as senior engineer: additive technologies. She then joined TRUMPF as industry manager, aerospace & medical. She also serves as Women in 3D Printing ambassador for Las Vegas and is the recipient of the TCT Women in 3D Printing Award for 2022. She has written a book based on her experiences as a female engineer at SpaceX.