Cathodoluminescent lamps rival LEDs without using rare earths

Researchers from the Moscow Institute of Physics and Technology (MIPT) and Lebedev Physical Institute of the Russian Academy of Sciences have designed and tested a prototype cathodoluminescent lamp for general lighting. The new lamp, which relies on the phenomenon of field emission, is more reliable, durable, and luminous than its analogues available worldwide. The research was reported in the Journal of Vacuum Science & Technology B.

While LED lamps have become commonplace, they are not the only clean and power-saving alternative to incandescent lamps. Since the 1980s, engineers around the world have been looking into the so-called cathodoluminescent lamps as another option for general lighting purposes.

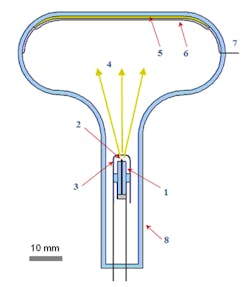

A lamp of this kind relies on the same principle that powered the old TVs using cathode-ray tubes: A negatively charged electrode, or cathode, at one end of a vacuum tube serves as an electron gun. A potential difference of up to 10 kilovolts accelerates the emitted electrons toward a flat positively charged phosphor-coated electrode--the anode--at the opposite end of the tube. This electron bombardment results in light.

Cathodoluminescent lamps have the advantage of being able to emit light almost at any wavelength, from the red to ultraviolet, depending on which fluorescent material is used.

Novel ultraviolet light bulbs would be a particularly timely development, considering the recent ban on household appliances using mercury under the Minamata Convention, a United Nations treaty signed by 128 countries that came into effect in August 2017. Among other products, the ban targets ultraviolet fluorescent tubes, widely used for greenhouse lighting and other applications. Cathodoluminescent UV light bulbs contain no mercury and are generally cleaner in service and upon disposal.

“Some industries using mercury lamps for water treatment and air disinfection, for example, will be very slow and unwilling to phase them out,” commented Mikhail Danilkin of Lebedev Physical Institute, RAS. “But medicine is different, because the issue of mercury lamp disposal at individual medical facilities has not been resolved, while the environmental standards are becoming stricter. Cathodoluminescent lamps could be used in operating room decontamination, UV irradiation of throat and tonsils, and dental filling curing.”

Another important advantage of the new lamp over LEDs and fluorescent bulbs is that it does not rely on the so-called critical raw materials. These include gallium, indium, and some rare-earth elements. While their supply is limited, these materials are essential and irreplaceable in the health, defense, aerospace, and other key industries. The European Commission lists them as strategically important for the European economy.

Attempts to mass-produce commercial cathodoluminescent light bulbs have been made in the United States, but the consumers did not embrace the device, mostly because it was bulky and took several seconds to warm up the cathode to operating temperature. Similarly, the old TV sets began displaying the image after a brief delay.

Some cathodes require no warmup, though. They are known as field emission cathodes, because they rely on the phenomenon of field emission. It involves a cold cathode emitting electrons under an electrostatic field alone, due to tunneling.

However, designing an efficient, long-lasting, and technologically advanced cathode that could be mass-produced and sold at an affordable price has proved challenging. Despite an ongoing effort in Japan and the U.S., the recent Russian study marks the first successful attempt at this.

The paper reports prototype tests and the lamp’s technical characteristics. These data suggest that if mass-produced, the new cathodoluminescent bulb could compete with the cheap lamps based on light-emitting diodes. The new bulb would also help phase out the hazardous fluorescent lamps containing mercury, which are still used in many households.

“Unlike the LED bulb, our lamp is not afraid of elevated temperatures. You can use it where diodes quickly fade, such as in ceiling spotlights, where insufficient cooling is provided,” added study co-author Dmitry Ozol from MIPT’s vacuum electronics department.

SOURCE: Moscow Institute of Physics and Technology; https://mipt.ru/english/news/russian_engineers_ready_to_light_up_a_lamp_revolution

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.