New automated NIST lab improves accuracy and shortens LED lamp calibration time

In June, the National Institute of Standards and Technology (NIST; Gaithersburg, MD) began offering a faster, more accurate and less labor-intensive calibration service for assessing the brightness of LED lamps and other solid-state lighting products. Customers for the service include LED lamp manufacturers, the U.S. military, and other calibration laboratories.

Well-calibrated lights ensure that the 60-watt-equivalent LED bulb in your desk lamp truly is equivalent to 60 watts, for example, or that there is proper runway lighting for the pilot in a fighter plane.

LED manufacturers need to ensure that the lamps they make are really as bright as they designed them to be. To do that, they calibrate those lamps with a photometer, a tool that measures brightness at all wavelengths while taking into account the human eye’s natural sensitivities to different colors.

For decades, NIST’s photometry lab has been meeting the industry’s needs by offering an LED brightness and photometer calibration service. The service involves measuring the brightness of customers’ LEDs and other solid-state lamps, as well as calibrating the customers’ own photometers. Until recently, the NIST lab has measured lamp brightness with reasonably low uncertainties--between 0.5% and 1.0%, on par with mainstream calibration services.

Now, thanks to the lab revamp, the NIST team has reduced those uncertainties by a factor of three, to 0.2% or less. The achievement makes the new LED brightness and photometer calibration service one of the best--if not the best--in the world.

“We have now reduced all major uncertainties,” said NIST researcher Yuqin Zong.

The scientists have also cut the calibration time significantly. With the old system, it took almost a full day to do a single calibration for a customer. Most of that was devoted to setting up each measurement--swapping out a light source or a detector, manually checking distances between the two, and then reconfiguring the equipment for the next measurement, said NIST researcher Cameron Miller.

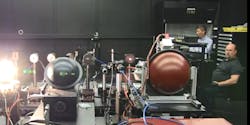

But now, the lab consists of two automated equipment tables, one for the light sources and the other for the detectors. The tables travel on a rail system that positions the detectors anywhere between 0 to 5 meters away from the lamps. The distances can be controlled to within 50 millionths of a meter (micrometers), which is about half the width of a human hair.

Zong and Miller can program the tables to move in relation to each other without requiring continuous human intervention. What used to take the better part of a day can now be done in hours.

“I don’t have to change any of the equipment anymore. Everything’s right here--all the instruments are in line, ready to be used,” Miller said. “It gives us a lot of freedom to do many things at the same time, because it’s completely automated. We could be back in our office doing other work while it’s running.”

NIST researchers say they expect their customer base to expand, since their lab has added several additional capabilities. For example, the new setup allows them to calibrate hyperspectral cameras, which measure many more wavelengths of light than typical video cameras, which usually capture only three or four colors. Hyperspectral cameras are becoming increasingly popular for everything from medical imaging to analyzing satellite footage of Earth. The information that space-based hyperspectral cameras provide about our planet’s weather and vegetation allows scientists to predict famines and floods and can help communities plan emergency response and disaster relief.

The new lab also allows researchers to more easily and efficiently calibrate smartphone displays and television and computer monitors.

Continue reading the full story at the source link below.

SOURCE: NIST; https://www.nist.gov/news-events/news/2019/09/brighter-future-leds-nist-introduces-new-lamp-calibration-lab

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.