Direct-diode Lasers: Direct-diode laser systems for materials processing show their power and efficiency

Although sometimes grouped with fiber lasers, so-called direct-diode lasers are actually very different beasts. While a fiber laser consists of a gain fiber that is end- or side-pumped, a direct-diode laser is actually made up of a non-gain optical fiber that is simply filled with light that originates from a multitude of laser diodes coupled to the fiber.

Both fiber lasers and direct-diode lasers in high-power forms are used for materials processing. While high-power fiber lasers can be had with either single-mode or multimode outputs, high-power direct-diode systems are always multimode, due to the fact that the etendue of optics for combining light from many laser diodes will be substantially above the single-mode limit. Nevertheless, direct-diode makers are continually improving the brightness of their products—in addition, many materials-processing applications do not require a single-mode beam. Most, but not all, direct-diode lasers emit in the near-infrared (near-IR).

While this article cannot include more than a portion of the direct-diode products available in today’s market, a representative sampling of what can be found is presented here.

Flexible beam characteristics

In the near-IR around 1 µm, a single-mode laser beam would have a beam-parameter product (BPP) of about 0.3 mm-mrad, which is unachievable by direct-diode lasers, which have a BPP that can range from a few to a few tens of mm-mrad. For example, II-VI (Kleinmachnow, Germany) produces a variety of direct-diode laser products with power levels from a few watts to multikilowatt systems, as well as many types of single laser-diode emitters and bars that it can use in its direct-diode laser products. “All systems in the lower- to medium-power-level range are based on II-VI’s proprietary single-emitter laser diodes,” says Haro Fritsche, manager of business development and technologies at II-VI. “By vertically stacking multimode, high-power single emitters and using polarization beam combining, a BPP of about 6–15 mm-mrad is achieved in a small, conductively cooled assembly with power levels of up to 300 W. II-VI integrates these assemblies into a broad portfolio of fiber-pigtailed modules for fiber-laser pumping. These assemblies are also integrated into turnkey direct-diode laser systems with detachable fibers, such as II-VI’s DirectLight900 product line, which can achieve very high power and is ideal for materials-processing applications.”

In the DirectProcess900, the high-power beam is achieved by wavelength-multiplexing the laser stacks and polarization-combining submodules, says Fritsche. This approach enables the DirectProcess900 to achieve a BPP of 6 mm-mrad over a broad range of power levels from 100 W to beyond 1000 W. The flat-top beam profile can then be delivered to the workpiece in free space or through fibers with a core size of 100 or 200 µm. Due to the wavelength multiplexing, these systems emit within a wavelength range of 900 to 980 nm.

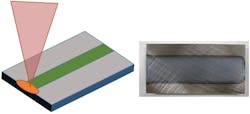

For further power scaling, II-VI recently extended the DirectProcess900 product line with a high-power, wavelength-stabilized bar-based module featuring a flat-top beam profile and a BPP of 5 mm-mrad, notes Fritsche (see Fig. 1). The base module achieves a bandwidth of less than 25 nm and an output power of 1.5 kW. These basic modules can be used for direct applications like cutting and welding as well as for high-energy laser pumping. Wavelength multiplexing extends the power levels of this platform far into the multikilowatt range without any change in beam characteristics. Cooling systems and driver electronics will soon be available for these products, says Fritsche. II-VI also produces beam-delivery products such as high-power fiber-optic cables and laser processing heads.

The DirectProcess900 FlexShape light engine has a free-space rectangular BPP of 6 mm-mrad and is equipped with a remote-controlled variable beam shaper to generate rectangular beam profiles with length and width individually adjustable on the fly from 0.2 mm to more than 50 mm. This allows it to excel in applications that require rectangular beams of adjustable length and width while maintaining a highly uniform beam intensity profile, says Fritsche. “The system is ideal for soldering microelectronic parts, where relatively small spot sizes ranging from 0.2 to 3 mm are adjusted over a fairly long working distance,” he says. “These long working distances are enabled by the low BPP of the laser system. The workpiece area is uniformly illuminated by the flat-top beam profile. By utilizing a flexible spot size, the FlexShape option offers customers the ability to use one laser system for all soldering geometries.”

Power levels between 800 and 1200 W are offered in rack-mounted assemblies that are 2 RU in height and 19 in. in width. “Another key feature of the system is its very short rise- and fall-times of less than 10 µs, while maintaining a very uniform power distribution across the beam, making this laser system ideal for numerous heat treatment applications,” says Fritsche. The DirectProcess900 can also be had with linear polarization, which is achieved by replacing the polarization coupling with wavelength multiplexing. By keeping the laser beam polarization aligned with the cutting direction, cutting quality and speed increase significantly.

“Another benefit of direct-diode laser systems such as the DirectProcess900, compared with pumped laser systems such as fiber lasers, is the ability to operate at lower wavelengths and a broader bandwidth, typically between 900 nm and 980 nm, to achieve better absorption in some materials such as silicon and aluminum,” Fritsche explains.

Tens of kilowatts

The optical outputs of some high-power direct-diode systems are equivalent to those of high-end fiber lasers—and, because direct-diode systems are based entirely on highly efficient laser diodes, they have much higher wall-plug efficiency than fiber lasers.

Lasertel (Tucson, AZ) manufactures high-power direct-diode laser systems that are tailored for individual materials-processing applications; optical output powers can be had from 100 W to more than 50 kW CW and more than a megawatt pulsed, says John Goings, sales director of Lasertel. Supported applications for these systems include carbon-fiber composite joining, food packaging, cladding and semiconductor-substrate heating.

“Lasertel’s T6 laser diode array offers configurations with powers up to 25 kW peak power or 2 kW average power, with available wavelengths from 760 nm to 1700 nm,” says Goings. “With the addition of tailored collimating and conditioning micro-optics, the optical energy can be shaped to heat application-specific work areas such as lines, rectangles, or anything in between.”

Goings adds that the T6 has been used as a heat source inside automated fiber placement (AFP) machines. The AFP tools use the optical energy of the laser-diode source to heat resins impregnated with nonmetallic fibers for carbon-fiber composite joining. “For traditional AFP tools, electrical coils were used, which are inefficient and limited in terms of throughput,” he says. “Laser diodes provide higher than 60% electrical-to-optical conversion efficiency, narrow wavelengths that are optimized to match optical absorption of the composite material, and tailored beam shapes to uniformly heat the workpiece. Laser-diode sources have taken over as the heat source of choice. The free space design of the T6 offers a substantially smaller form factor compared to fiber-delivered laser diodes. Individual arrays can be turned on and off by the operator to control the amount and speed of the material processed.”

Kilowatt-level workhorses

Designed for precision materials-processing, the BDL-CW series from BWT (Beijing, China) is a direct-diode system offering 1000, 2000, or 3000 W output power with an output wavelength of either 915 or 976 nm. RPMC Lasers (O'Fallon, MO) is the North American distributor for BWT. “This turnkey system, based on a multiple single-emitter design using fused fiber combining, has achieved 1000 W output power from a 300 μm fiber and 3000 W output from a 600 μm fiber,” says Dean Micke, president of RPMC Lasers. “The system features a simple architecture, single-wavelength, direct-diode output with moderate brightness. The kilowatt direct-diode laser system comes standard with QBH [fiber-optic] connector, which is compatible with most commercial processing heads. The flat-topped beam from the laser system provides a uniform energy distribution. Compared to other types of lasers, the kilowatt direct-diode laser system has higher wall-plug efficiency, is more compact, and offers a competitive price.”

The BDL-CW series has uses that include welding, cladding, surface treatments, and lithium-ion battery manufacturing. With two operational modes, continuous mode and pulse mode, the heat-affected zone (HAZ) can be minimized, says Micke. The system can be operated in harsh industrial application environments.

In-house chip and optics manufacture

A line of direct-diode systems by Hamamatsu (Hamamatsu City, Japan) also hits the one- to few-kilowatt-level output powers that are so often needed in laser-based materials processing. The company’s DDL (direct-diode laser) system is based on a stacked laser-diode module with an output of up to 1 kW at 940 nm, which is stacked to produce higher output levels.

“Hamamatsu carries out laser-diode chip production, water-cooling heat-sink production, modularization, and assembly in-house under high-quality control,” says Toshiaki Kakei, manager of overseas sales at Hamamatsu. “This is the reason we can produce high-reliability laser applied products that can be used in an actual industrial production line for a long period of time.” The company achieves high-uniformity beams for their direct-diode units using optics made in-house, he adds.Uses include surface hardening (see Fig. 2), cladding, welding, and heating, as well as pumping for solid-state lasers. “We are focusing on more uniform hardening and cladding,” notes Kakei. A high-uniformity (top-hat) beam can prevent melting caused by overheating in the central area or lack of hardness in the peripheral area due to less heating, which arises when using a Gaussian beam shape.”

Blue for processing copper

Until recently, only near-IR direct-diode lasers had enough power for materials processing applications such as welding, cutting, and cladding. Nuburu (Centennial, CO) has changed the game by introducing blue direct-diode systems that achieve high power by combining the outputs of two-dimensional laser diode arrays (see Fig. 3). “To maintain beam quality, which translates into brightness and, in turn, power density, each diode is individually circularized and collimated with a dedicated micro-optic,” says Jean-Michel Pelaprat, cofounder and chief marketing officer at Nuburu. “These ‘beamlets’ are then combined using both spatial interleaving and polarization control. The combined beamlets are focused into an optical fiber. The baseline systems can be combined to deliver more than 1 kW into a 440 µm spot on a workpiece."Blue light is ideal for welding copper and similar metals, because it is absorbed 20% more readily than green light and more than 10X as efficiently as infrared radiation, explains Pelaprat. Copper welding is more efficient with blue light than with other wavelengths, but efficiency doesn’t mean anything without sufficient power density.

“Two AO-500s coupled through a BlueWeld welding lens delivers about 800 kW/cm2, sufficient to weld a 1.5 × 3 mm hairpin joint defect-free,” Pelaprat says. “Hairpin joints are required for bar-winding electric motors—a dense, efficient motor design rapidly being adopted by electric-vehicle manufacturers. The blue laser produces a more compact joint than any alternative technology, and at current output levels is now powerful enough to be integrated into electric-motor fabrication processes.”

Pelaprat adds a final note about blue welding: the high material absorption means that the same power density is required to maintain a weld as to start the weld. “That’s not true of other wavelengths, which must tread a very thin line between providing enough energy to start the weld and not so much that material is vaporized out of the joint,” he says. “That vaporization leads to particulate deposition (called ‘spatter’) and holes in the joints (‘voids’). The blue laser creates welds that are essentially spatter and void-free.”

The Nuburu laser is used to perform welds (metal joints) with copper or aluminum to a very high quality (meaning high mechanical and electrical performance). The quality is defined by a weld with no spatter and no defects in the joint. The laser is used for lithium-ion battery cell production, welding copper or aluminum electrodes to battery tabs and, later on in the process, from tabs to bus bars.

FOR MORE INFORMATION

Companies featured in this article include:

BWT

Beijing, China

Hamamatsu

Hamamatsu City, Japan

II-VI

Kleinmachnow, Germany

Lasertel

Tucson, AZ

Nuburu

Centennial, CO

RPMC Lasers

O'Fallon, MO

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.