Ultrashort-pulse Lasers: Ultrashort-pulsed laser sources with kilowatt power for industrial applications

Having found early wide-scale use in mobile device glass scribing applications, ultrashort-pulse (USP) lasers in the picosecond (ps) or even femtosecond (fs) range have been available for more than a decade. The ability to process numerous materials with micron precision—without splatter or thermal side effects—promises to expand the range of potential applications for industrial USP lasers. However, USP laser use in applications that require high repetition rates and high power to achieve economically viable throughput have been limited.

The problem is that while a few USP laser sources on the market may exceed 150 W or 150 µJ per pulse, most deliver less. Even if stronger sources were available, using the additional power is a challenge because ultrashort pulses lose their “cold ablation” capability when too many of them are focused into one spot.1

Understanding this challenge, the German Fraunhofer-Gesellschaft has identified USP laser systems as a great opportunity and put together the expertise of not less than 13 of its institutes to develop a new generation of such systems. The Fraunhofer Cluster of Excellence Advanced Photon Sources (CAPS) plans to not only overcome USP laser power limitations, but also develop technologies along the process chain from pulse generation to process technology, and real-world applications.

Upscaling to kilowatt power

The CAPS project is managed by the Fraunhofer Institute for Laser Technology (Fraunhofer ILT; Aachen, Germany) and the Fraunhofer Institute of Applied Optics and Precision Engineering (Fraunhofer IOF; Jena, Germany). Both institutes will host application laboratories and have dual facilities to enable parallel development of laser sources and application tests. The site in Aachen opened in September 2019, and the one in Jena will start operation early in 2020.

The problem of converting power into throughput will require new process technology for USP laser systems, which starts with basic research on laser matter interaction at high repetition rates and high pulse energies.1 Another challenge is power distribution: one concept for pulses with higher energy involves splitting the beam into many parallel beamlets.2 A large number of similar beamlets enables parallel processing, and processing patterns with periodic structures that may allow the potential realization of substantial productivity gains.

Another approach involves building acousto-optical modulators into the beamlets, yielding a kind of laser matrix printer that can be realized by switching single beamlets on and off. In a third and extremely flexible version, the beamlets can be sent through a liquid crystal modulator that can generate almost any pattern or beam properties from the original beam.

These rather sophisticated solutions are developed in parallel to more conventional high-speed scanner technology. Such polygon scanners are applied within CAPS, and achieve scanning speeds >300 m/s. For the development of efficient scanning strategies, the project will use a software for a detailed simulation of the physical processes during and after the laser absorption. With this tool from Fraunhofer ILT, thermal effects can be studied, and processing patterns can be tested.

The slab concept

One key to creating high-power ultrashort laser pulses is finding the right amplification scheme. A recent Industrial Laser Solutions article detailing techniques for upscaling towards 100 W and more discusses fiber and slab/rod concepts. CAPS project researchers will also implement such concepts with very specific advances that will enable substantial progress towards 10 kW average power. One is based on coherently coupled fiber amplifiers, while the other one uses specific diode-pumped slabs.

The slab laser system is based on the Innoslab concept as patented back in 1996 by Keming Du and Peter Loosen. At that time, Keming worked at the Fraunhofer ILT—just five years later, he founded EdgeWave (Würselen, Germany) to exploit the idea commercially. At Fraunhofer ILT, the Innoslab concept was further refined, and today, it is applied for a kilowatt-class USP laser amplifier.3 Based on these results, another spinoff company, AMPHOS, has been founded.

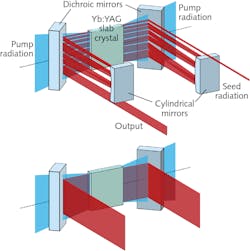

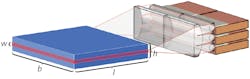

The resonator setup of an Innoslab laser is based on a rectangular crystal between two heat sinks that is longitudinally pumped by collimated laser diodes (see Fig. 1). Originally, the design was developed with continuous-wave (CW) pumped Nd:YVO4 and Nd:YAG laser crystals. Several crystal materials for different purposes have been demonstrated; for short-pulsed systems with subpicosecond-pulse duration, ytterbium-doped crystals turned out to be most favorable.

Figure 1 shows the setup of an Innoslab amplifier. In the center is the partially end-pumped slab crystal. Beside the crystal are two mirrors, which fold the beam several times. The slab crystal has two optical surfaces with antireflective coating for the pump light and the amplified laser beam. The crystal is mounted and cooled on its two large surfaces. The four uncoated surfaces are grinded to suppress parasitic lasing.

The crystal is end-pumped on a rectangular cross-section of a high aspect ratio, which only fills a fraction of the crystal in the y-direction and the full width in the x-direction. This geometry matches the emission characteristics of laser diode bars. The short distance between the pumped gain volume and the large cooled mounting surfaces allows for efficient heat removal. The one-dimensional heat flow establishes a homogeneous cylindrical thermal lens and avoids depolarization by birefringence.The fiber concept

The fiber amplifier within the CAPS project builds upon the fiber laser experience collected in a close collaboration between Fraunhofer IOF and the institute of Applied Physics at Friedrich-Schiller University (also in Jena, Germany). Their fiber amplifier systems achieved a number of records, including 4.3 kW single-mode output in CW operation.5

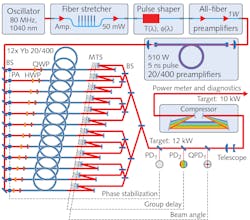

The principal setup for fiber amplifiers is well known (see Fig. 5). The pulses from a seed oscillator are stretched, amplified, and recompressed. The actual limitation of this method comes with the impact of harmful nonlinear effects and the damage threshold of the fibers. The amplified beam must fit into the fiber core, which is rather small. One approach is the employment of amplifying large-mode area fibers, a direction the fiber laser groups in Jena have pursued for many years.To scale the performance even further beyond the limitation of a single-aperture fiber, a new approach is needed. One solution is to split the beam into a number of replicas, which are amplified while the intensity is kept below the critical level, and then coherently recombined into one beam.

However, the actual challenge is in the coherent recombination.6 In this method, the linearly polarized beam is split into two beams with perpendicular polarization. After amplification, the beams are recombined in the same way they have been separated, with a polarization beamsplitter. This method requires perfect spatial and temporal overlap for recombination—therefore, all beams have active phase stabilization systems.

The method works well and has achieved a combining efficiency as high as 97%, and has two advantages. First, there is no limit in the number of partial beams, and second, the amplification scheme is independent of the architecture of the gain medium.

While the older setup used four amplifier lines to generate 3.5 kW average power,7 a new and upgraded system is based on 12 parallel fibers (see Fig. 6). In recent tests, it delivered an average power of 8.9 kW in single-mode radiation with a beam quality M2 <1.2.Further optimization towards more than 10 kW is planned for early 2020. The compressed pulses have a duration as short as 250 fs. Subsequent modules will either allow a pulse shortening towards few-cycle pulses or a conversion to spectral regions of interest for many applications, ranging from terahertz to the soft x-ray.

This source will be available for the other Fraunhofer teams for application experiments in the Jena-based lab. There will be an additional laser system in this lab that converts the high-energy pulses into ultrashort extreme ultraviolet (EUV) pulses of 20 to 90 eV (60 to 13 nm).

Application development

As mentioned earlier, the sources will be further developed in parallel to the development of appropriate process technology. The application labs offer several beam sources, extensive diagnostics, and an increasing set of beam delivery technologies.

Most of the 13 partners in the CAPS collaboration are working on applications of these new USP laser sources. Their activities are organized in four topical groups:

System technology and components. Besides the actual high-power laser development, this group focuses on the technologies for distribution, conversion, simulation, and measurement of the ultrashort pulses.

Production. The final ambition of the CAPS project is the introduction of USP laser systems in large-scale production processes with high throughput. Texturing solar cells or applications in the manufacturing of batteries are some of the ideas, which will be developed with the new lasers.

Imaging. The conversation of the powerful laser radiation either in coherent infrared or EUV beams will enable new and efficient imaging processes for nondestructive analysis of technical or biomedical materials. Even shorter wavelengths could be achieved with laser-driven Compton sources.

Materials. USP lasers in the range of 10 to 20 kW will enable the efficient production of entirely artificial materials. Additional options will be in the research of materials for quantum technologies such as nitrogen-vacancy (NV) diamonds.

Outlook

CAPS, currently with its 13 partner institutions, embarks on developing a new generation of high-average-power USP laser systems. The collaboration uses two application labs with fiber- and slab-based amplifiers producing several kilowatts of subpicosecond laser pulses. In parallel to the laser sources, beam delivery technology is developed to make effective use of the radiation. While the partners develop a range of new technologies, their ambition is actually to make the USP laser a tool with average powers of current CW fiber lasers plus the unique features of USP lasers, including high precision and low or no dependency on the processed material. The CAPS user facility is also open for testing and demonstration of new applications from industry. For more information and contacts on the CAPS, please visit www.caps.fraunhofer.de.

REFERENCES

1. J. Finger et al., Adv. Opt. Technol., 7, 3, 145–155 (2018).

2. A. Thoss and J. Finger, “High throughput USP laser micromachining,” Industrial Laser Solutions (Jan/Feb. 2020); http://bit.ly/ILSRef2.

3. P. Russbueldt et al., IEEE J. Sel. Top. Quantum Electron., 21, 1, 3100117 (Jan/Feb. 2015).

4. P. Russbueldt et al., Opt. Lett., 44, 5222–5225 (2019).

5. T. Schreiber, A. Tünnermann, and A. Thoss, Laser Focus World (2017); http://bit.ly/LFWRef5.

6. E. Seise, A. Klenke, J. Limpert, and A. Tünnermann, Opt. Express, 18, 26, 27827 (2010).

7. M. Müller et al., Opt. Lett., 43, 24, 6037–6040 (2018).

Andreas Thoss | Contributing Editor, Germany

Andreas Thoss is the Managing Director of THOSS Media (Berlin) and has many years of experience in photonics-related research, publishing, marketing, and public relations. He worked with John Wiley & Sons until 2010, when he founded THOSS Media. In 2012, he founded the scientific journal Advanced Optical Technologies. His university research focused on ultrashort and ultra-intense laser pulses, and he holds several patents.

Hans Dieter Hoffmann | Head, Department for Laser Development at the Fraunhofer Institute for Laser Technology

Hans Dieter Hoffmann is head of the department for laser development at the Fraunhofer Institute for Laser Technology (Aachen, Germany).

Jens Limpert | Professor for Physics, Department of Fiber & Waveguide Lasers at Friedrich Schiller University

Jens Limpert is Professor for Physics and leads the department of Fiber & Waveguide Lasers at Friedrich Schiller University (Jena, Germany).