Light-emitting Diodes: Al-inorganic silicon white-light LED has 1.0% efficiency

The common white-light LED, found across the world in energy-efficient lamps and other light fixtures, is a combination of a blue-emitting semiconducting aluminum gallium nitride (AlGaN) LED and a blue-absorbing, yellow-emitting YAG phosphor. While these emitters have revolutionized the lighting industry, some have concerns over the use of gallium in the LED and yttrium in the phosphor, as these are relatively uncommon materials that could conceivably become rarer and higher-priced over time.

One of the most common semiconducting materials, silicon (Si), widely used in electronic chips, photonic integrated circuits, and photovoltaic cells, could be a potential replacement for AlGaN in LEDs, but for one flaw—Si, like other group IV semiconductors, is an indirect-bandgap semiconductor that ordinarily can’t be made to emit light except at extremely low levels. Attempts to extract more light from Si have included making Si into nanocrystals or quantum dots and/or combining Si with organic materials. However, the results have either been nonwhite emission, very low efficiency, or short lifetime.

Scientists from Fudan University, (Shanghai, China), Guizhou Minzu University, (Guiyang, China), and the Nanjing Electronic Devices Institute (Nanjing, China) have taken a different approach, resulting in the creation of an inorganic Si white LED with an external quantum efficiency of 1% for the first prototype. The LED has a luminance of 225.8 cd/m2 (which is not far from the standard value for a commercial display), an onset voltage of 2.9 V, and a warm white appearance.

Annealing temperature affects spectrum

The LED has an active layer composed of high-density Si nanocrystals embedded in hydrogen silsesquioxane (Si-NCs:HSQ). The Si-NCs were differentially passivated, resulting in broad-spectrum white-light emission. A 4-in. Si wafer was cut into pieces 2 × 2 cm in size, which were coated and processed in various steps, including annealing, to form the LEDs, which had aluminum as a back electrode and indium tin oxide (ITO) as a front electrode. Annealing at different temperatures produced LEDs with different spectra.

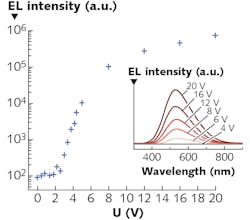

Annealing of the HSQ film resulted in a composite thin film of Si-NCs embedded in silicon dioxide (SiO2), with an average spacing between the nanocrystals of about 1 nm and crystal size of 2.8 ±0.4 nm. Depending on the annealing temperature, the finished LED emitted either a cool-white or a warm-white light, with the most-efficient device having a color-correlated temperature of about 4900 K. Also, increasing the bias voltage across the LED caused the central wavelength to shift more toward the blue as the intensity increased (see figure).

The researchers believe that this is the first demonstration of an all-inorganic Si LED (at other than minuscule efficiency).

REFERENCE

1. C. Zhang et al., Opt. Express (2019); https://doi.org/10.1364/OE.382691.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.