Laser-induced graphene written by blue laser could be basis for flexible electronics

Scientists at Rice University (Houston, TX), the University of Tennessee, Knoxville (UT Knoxville), and Oak Ridge National Laboratory (ORNL) are using a focused visible laser beam to create microscopic patterns of laser-induced graphene (LIG) on polymer.1 The labs of Rice chemist James Tour, which discovered the original method to turn a common polymer into graphene in 2014, and Tennessee/ORNL materials scientist Philip Rack revealed that the scientists can now watch the conductive material form as it makes small traces of LIG (which takes the form of a graphene foam) in a scanning electron microscope (SEM).

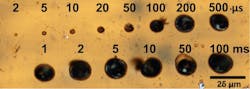

The altered process uses a 405 nm wavelength to create LIG with features more than 60% smaller than the macro version and almost 10 times smaller than typically achieved with the infrared laser formerly used. Lower-powered lasers also make the process less expensive, says Tour. The process could lead to wider commercial production of flexible electronics and sensors.

“A key for electronics applications is to make smaller structures so that one could have a higher density, or more devices per unit area,” Tour notes.

To prove the concept, the lab made flexible humidity sensors that are invisible to the naked eye and directly fabricated on polyimide, a commercial polymer. The devices were able to sense human breath with a response time of 250 ms.

The SEM-mounted laser burns only the top 5 µm of the polymer, writing graphene features as small as 12 µm.

Tour, whose group recently introduced flash graphene to rapidy turn trash and food waste into graphene, says the new LIG process offers a new path toward writing electronic circuits into flexible substrates like clothing.

“While the flash process will produce tons of graphene, the LIG process will allow graphene to be directly synthesized for precise electronics applications on surfaces,” Tour says.

Source: https://news.rice.edu/2020/02/12/graphene-forms-under-microscopes-eye/

REFERENCE:

1. Michael G. Stanford et al., ACS Applied Materials & Interfaces (2020); https://doi.org/10.1021/acsami.0c01377

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.