High-color-purity UV OLED has asymmetric microcavity design

Ultraviolet organic light-emitting devices (UV OLEDs) are expected to develop into mass-producible, large-sized UV light sources for industry and the medical arena. However, most UV-emitting organic materials have broad emission spectra, and thus the electroluminescence (EL) of the most common UV OLEDs have significant visible light components that can limit the uses of these sources. The development of a narrowband pure UV emission OLED with considerable irradiance and satisfactory durability in practical applications is still a challenge, but a research group led by Liu Xingyuan from the Chinese Academy of Sciences (Beijing, China) has developed a high-color-purity OLED by introducing simple optical structures into the device.

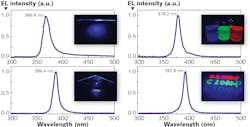

The microcavity (μC) UV OLEDs were constructed using an asymmetric structural design with a specific distributed Bragg reflector (DBR) structure. The researchers found that the asymmetric microcavity could effectively suppress the visible light component, leading to narrowband pure UV emission with tunable wavelength from 366 nm to 400 nm, a full width at half maximum (FWHM) bandwidth from 9.95 to 15.2 nm, and a maximum irradiance of 2.79 to 5.63 mW/cm2. The μC UV OLEDs showed improvement over other devices both in irradiance and lifetime, owing to the enhanced carrier injection and precise regulation of the exciton recombination region in the ultrathin microcavity. Reference: J. Lin et al., ACS Appl. Mater. Interfaces (2020); https://doi.org/10.1021/acsami.9b20212.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.