Phosphate glasses can serve as visible-luminescence materials

Visible luminescence of terbium (Tb3+) ion-doped materials has found various applications in display techniques, visible-light communications, and medical treatments. Fluoride glasses are commonly used as a host material for gain fiber due to their low-energy phonon distribution; unfortunately, poor chemical and mechanical properties, fabrication difficulties, and expensive cost limit development and further applications of luminescent doped fluoride glasses.

Phosphate glasses instead

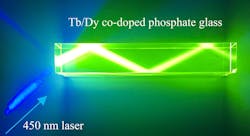

Now, a research team from the Shanghai Institute of Optics and Fine Mechanics of the Chinese Academy of Sciences has succeeded in strengthening the absorption of Tb3+ ions by introducing a dysprosium (Dy3+) sensitizer in phosphate glasses.1

In their experiment, Tb3+/Dy3+ co-doped phosphate glasses were synthesized as a function of Dy3+ ion concentration by mature processing techniques. The element distributions, phases, absorption, emission spectra, and fluorescence lifetimes of Tb3+ and Dy3+ ions, as well as the energy transfer mechanisms, were characterized and investigated. Homogeneous element distributions and uniform noncrystalline phases showed that the phosphate glasses were high-quality.

The researchers found that the large so-called "Judd-Ofelt" parameters Ω2 and Ω4/Ω6 for Tb3+ ions could reach up to 21.60 × 10-20 cm2 and 0.73, respectively. Efficient sensitizing by Dy3+ for visible emission of Tb3+ was demonstrated, and a maximum energy transfer efficiency 55.0% for a 4:0.5 ratio of Tb3+/Dy3+ at a 425-nm pump wavelength was shown.

Moreover, as a long lifetime of fluorescence decay is favorable for more-efficient laser operation, a long lifetime (2.86 ms) for the Tb3+: 5D4 level in Tb3+/Dy3+ co-doped doped phosphate glasses was measured a lifetime much longerer than those in other kinds of glasses.

This research may lead to a host material for fiber lasers operated at visible wavelengths, say the researchers.

Source: http://english.cas.cn/newsroom/research_news/phys/202008/t20200827_242115.shtml

REFERENCE:

1. Yan Sun et al., Journal of the American Ceramic Society (2020); https://doi.org/10.1111/jace.17391.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.