Colloidal quantum-dot light emitters go broadband in the IR, can be electrically driven

Broadband light emission in the infrared is key to a large range of applications, including food quality and product/process monitoring, recycling, environmental sensing and monitoring, multispectral imaging in automotive, and safety and security. With the advent of the Internet of Things (IoT) and the increasing use of portable electronic devices, the introduction of on-chip spectrometers for health monitoring, allergen detection, and food-quality inspection, to name a few uses, is expected to happen soon. A small, highly efficient, and ideally CMOS integrated IR light source would boost the use of on-chip IR spectrometers.

Broadband light emitters in the shortwave infrared (SWIR) conventionally come in the form of blackbody radiators, whose thermal basis does not allow miniaturization. Furthermore, heat dissipation becomes a major issue when it comes to integration of such sources in compact portable systems. What makes matters even worse is the fact that these sources are uncontrollably broadband, making them highly inefficient, since most of the generated light is essentially useless.

To address this challenge, researchers at ICFO – The Institute of Photonic Sciences (Barcelona, Spain) have developed a new class of broadband solid-state light emitters based on colloidal quantum-dot (CQD) thin-film technology.1 CQDs offer the advantages of low-cost solution processability, easy CMOS integration, and a readily tunable bandgap. Taking advantage of these properties, ICFO researchers designed and engineered a multistack of CQDs of different size that turned out to be capable of emitting light with a spectrum that depended on the size of the emitting QDs.

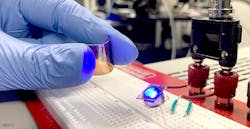

The sequence and thickness of the layers was optimized to maximize the photoconversion efficiency of this downconverting nanophosphor type of thin film. The stacks were built on top of a flexible plastic substrate, which was then glued on top of an LED emitting in the visible range. The visible LED light was then absorbed and converted by the CQDs to IR light with a desired spectrum and, more importantly, with a very high photon-conversion efficiency of 25%. The researchers showed that the shape of the emission spectrum can be tuned by choosing the appropriate populations of CQD sizes. For this particular case, the researchers developed a broadband light source covering an emission range between 1100 and 1700 nm with a full width at half maximum (FWHM) of 400 nm.

Electrically driven version also created

Then, by exploiting the conductive nature of the CQD thin films, the researchers were able to take a step further in their experiment and also construct electrically driven active broadband LEDs with a FWHM in excess of 350 nm and quantum efficiency of 5%. This is the first monolithic electrically driven broadband SWIR LED that does not need to rely on external light sources for excitation. This is a useful discovery, as current available technologies based on III-V semiconductors not only are CMOS incompatible, but also require the use of multiple indium gallium arsenide (InGaAs) chips in the form of an array to deliver a broadband spectrum, which adds complexity, cost, and device volume increase.

Finally, to demonstrate how suitable this technology could be for market applications based on spectroscopy techniques, the team of researchers searched for several real-case examples that could be good candidates for such technology. They took their CQD light source setup and, putting it together with commercially available spectrometers, they were able to distinguish between different types of plastics, liquids, and milks that have distinct spectral signatures in the SWIR. The successful results open a new realm for the field of SWIR spectroscopy, since they prove that this technology could be used for applications that range from plastic sorting in recycling to health and safety or food inspection, to name a few.

Source: https://www.icfo.eu/newsroom/news/article/4836

REFERENCE

1. Santanu Pradhan, Mariona Dalmases, and Gerasimos Konstantatos, Advanced Materials (2020); https://doi.org/10.1002/adma.202003830.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.