Pioneering the petawatt regime at ELI-Beamlines

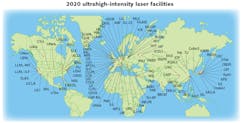

With more than 50 extreme-power laser installations in use or in development across Europe, Asia, and the U.S., international leadership has helped realize a world linked by ultrafast, ultrahigh-intensity laser systems with petawatt-regime capabilities. This tremendous global investment has opened the door to unprecedented opportunities for collaborations in the pursuit of science across nations, borders, and throughout the public-private sector.

In May 1996, researchers at Lawrence Livermore National Labs (LLNL) generated the first petawatt laser pulse, with 1.25 PW of peak power. With this demonstration, visions for extreme-power laser installations around the world capable of generating more than 0.1 PW began to materialize. Over the following 25 years, various facilities such as Vulcan, Orion, Gekko XII, PHELIX, SULF, Omega EP, PETAL, SG-IV, PEARL, and CETAL—to name a few—were commissioned and became operational in locations around the globe. Today, the lasers at these facilities use pico- to femtosecond pulse durations to reach petawatt-level power, and support research that will ultimately benefit medicine, telecom, engineering, materials science, industry, and energy (see Fig. 1).

ELI-Beamlines: L3-HAPLS

Extreme Light Infrastructure, or ELI, received in 2009 a commitment of financial support from the European Commission (EC) and 13 partner nations to build the most modern laser equipment in the world. Its mission is to carry out research and application projects involving the interaction of light with matter at an intensity of about 10X greater than was achievable at that time. This goal is now in reach.

Today, ELI consists of three extreme-power laser facilities: ELI-ALPS (Attosecond Light Pulse Source) in Szeged, Hungary; ELI-Beamlines in Dolní Břežany near Prague in the Czech Republic; and ELI-NP (Nuclear Physics), located in Magurele, Romania.

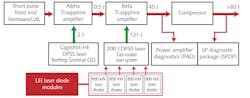

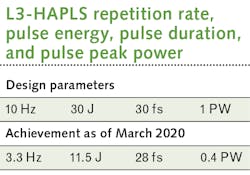

The ELI-Beamlines center, which has been open to research since 2018, constitutes four lasers that reach six experimental halls, E1 through E6. The state-of-the-art laser systems, with peak powers ranging from 5 TW up to 10 PW, are referred to simply as L1, L2, L3, and L4. The L3-HAPLS stands for the LLNL-developed High-repetition-rate Advanced Petawatt Laser System. With two titanium-doped sapphire amplifiers and a 200 J-level pump laser boosted by four array modules of the world’s highest-peak-power pulsed laser diodes, the ultracompact system—built in just three years—was installed at ELI-Beamlines in December 2017 (see Fig. 2).ELI: Inroads to innovation

In 2013, the Livermore Lab was awarded approximately $45 million to develop and deliver HAPLS, a system of complexity and nuance that necessitated creative approaches and collaboration at nearly every step along the path to completion. Among the innovations are the creation of an integrated control system and timing interface to synchronize HAPLS to the ELI-Beamlines master clock and a pump system based on laser diodes to be envisioned, designed, and built. Flashlamps had, of course, been the prevailing pump source for petawatt-level systems and were capable of delivering the requisite massive amounts of energy, but obvious drawbacks, including the unalterable broadband spectral output, high heat load, and power-hungry cooling systems, were simply too problematic. By transferring less heat than flashlamps, a diode-based system would prove to be the best method for reducing the time between laser shots and achieving the sought-after high repetition rates. Additionally, a pulsed-power system to drive those diode arrays would also have to be developed by the lab’s team.

In early 2014, LLNL contracted with Femtolasers Produktions (Vienna, Austria) and Leonardo Electronics US Inc. (then Lasertel of Tucson, AZ). Femtolasers would supply a state-of-the-art front end that relied on double-chirped pulse amplification to generate the ultrafast pulse at high stability with ultralow noise. A collaborative partnership with Leonardo would produce the diode modules.

Over months, the diodes were tested until the reliability was essentially flawless, demonstrating an expected lifetime of greater than 2 billion shots—more than six years of 24/7 operation at 10 Hz. On top of that, these diodes set a record for the brightest laser diode source in the world: more than 10 kW/cm2 for a multi-100 kW module, representing a total peak power of 3.2 MW. By February 2017, it had demonstrated continuous operation of an all-diode-pumped, high-energy femtosecond petawatt laser system. Unlike most high-power facilities the size of a sports field, HAPLS was a mere 17 × 4 m.

Diodes: The right enabling technology

While numerous breakthroughs were necessary to support the L3-HAPLS project, modules of laser diodes were (and still are) one of the more significant enabling technologies. Semiconductor lasers are responsible for the efficient conversion of electrical energy into light and have reached unprecedented power densities usable to be combined and achieve very high absolute power levels. It is because of this efficiency, modularity, and compactness that laser diodes are positioned to be the key technology supporting advanced classes of future-facing, high-energy systems.

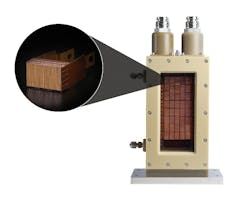

The diode arrays used in the ELI-Beamlines L3 laser (see Fig. 3) are designed and manufactured in a highly controlled manner with repeatability and reliability in mind. After the growth of the epitaxial structure, the wafer is cleaved into diode bars and their facets are coated using an in-house developed process called epitaxial mirror on facet (EMOF). In this unique process, a structurally matched passivation layer is grown onto the output facet of the diode as a single crystal to prevent oxidation and distortion of the band structure, resulting in catastrophic optical mirror damage. The EMOF process is a key factor in achieving the high peak power that enables such a compact package.The thermomechanical arrangement of these hard-soldered stacks on coolers with all rear-accessible facilities (electrical and cooling) is the second pillar in creating a modular and scalable concept maintaining the power density of the module. Arrays can be combined into rows and cooled by a common backplane, and rows can be combined into modules. The size of a 40-bar array measures 11 × 16.9 mm and a module, with 9 × 5 arrays, measures 57 × 156.4 mm.

Performance features

In terms of performance, peak power was driven initially to >500 W per bar with an efficiency of about 60%. Whereas average bars can achieve a damage threshold of around 40 mW/µm, Leonardo’s EMOF process enables >120 mW/µm, resulting in an outstanding peak power of >1 kW/bar—twice the brightness compared to the pumps for HAPLS. Arrays reached a maximum output power of >23 kW with a record power density of >11 kW/cm2. This performance was unprecedented. Today, with the 1 kW bars, the power density has reached 20 kW/cm2.

The current control system developed by LLNL, which includes granular manual control over the beam, eases adjustment and programming of the spatial and temporal profile of the beam, and controlling the pulse coming from each diode array. This is a key element of the system necessary to optimize the gain profile of the main laser.

Applications, future markets

Research at ELI-Beamlines and other petawatt-scale laser facilities is prolific. The long and varied list of topics studied includes:

- Plasma physics

- Particle acceleration

- X-ray phase-contrast imaging

- Radiation biology and ion radiation therapy

- High-pressure materials

- Insight into the structure of matter and the development of the universe

- The study of hot and dense nuclear matter

- Laser-driven colliders

- Fusion and high-energy density research

In radiation therapy, high-brightness, high-energy particle beams impose maximal destructive effect on the tumor while minimizing damage to the surrounding tissue. In some cases, particle therapy offers an alternative to more traditional photon radiation treatment. While this type of treatment is not yet widely available, it is already offered at a few hospitals in Europe. In the U.S., some states have received seed funding to invest in collaborative treatment facilities. The reduced cost and footprint might ease access for hospitals to such highly energetic beams and develop them more into a standard of care for the future.

Keys to commercialization

Nuclear fusion, which promises a zero-carbon energy source, is an enormously interesting solution to satisfy the growing global energy need without contributing to global warming. The global market size is estimated to be on the order of $13 trillion and fusion would be an inexpensive, virtually inexhaustible way to satisfy this need. Seemingly always 15–20 years out, new startup efforts and collaborations believe that demonstrated success is now perhaps only five years from fruition. While many of these commercial entities are pursuing non-laser-related fusion, there are some that are taking advantage of the unique properties of ultrashort-pulse lasers: the ability of generating near-relativistic particle beams in laser wakefield acceleration could enter ultrafast laser fusion drivers into a nonthermal regime where instabilities in plasmas (the biggest problem in achieving ignition for inertial confinement fusion) do not have the time to form.

The amount of laser-diode power needed to build such systems is very high, but the compactness, efficiency, and scalability gained from the experience with the L3-HAPLS diode approach may make the dream of a fusion power plant a reality.

There is much excitement about future-facing initiatives and, of course, still many unknowns. Two things are certain:

1. In 2021, L3-HAPLS will undergo a planned upgrade with the goal of reaching 1 PW of output power at 10 Hz repetition rate. The first step is to replace the four 800 kW modules with 900 kW modules. To maximize operational time and prevent disruption, the arrays will be upgraded individually; as one 800 kW module is removed, a spare (800 kW) module will place-hold until a new 900 kW unit is installed.

2. High-energy laser systems will continue to progress steadily in the direction of these ambitious goals, offering researchers capability gains across a range of applications.

Lucia Koubíková | Laser Systems Engineer, ELI-Beamlines

Lucia Koubíková is Laser Systems Engineer at ELI-Beamlines (Dolní Břežany, Czech Republic).

Lukas Gruber | Business Development, Leonardo Electronics US Inc.

Lukas Gruber is in business development at Leonardo Electronics US Inc. (Tucson, AZ).