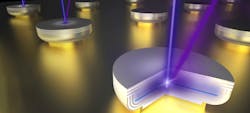

Electrochemically etched VCSEL emits at 310 nm, shortest wavelength yet

Researchers at Chalmers University of Technology, with collaborators at Technische Universität Berlin, have demonstrated the shortest wavelength ever reported of a vertical-cavity surface-emitting laser (VCSEL) which, if fully developed, could be used in, for example, disinfection and medical treatment. Previous efforts at short-wavelength VCSELs have reached down to about 360 nm; the new laser, which is optically pumped and operates at room temperature, emits at 310 nm, which falls in the ultraviolet B spectrum (280–320 nm).

To realize the UV emission wavelengths in the ultraviolet B (UVB; 280–320 nm) or ultraviolet C (UVC; 200–280 nm), needed for disinfection applications, a VCSEL must be aluminum gallium nitride (AlGaN)-based. Researchers at Chalmers University of Technology (Gothenburg, Sweden), Technische Universität Berlin (Germany), and Ferdinand-Braun-Institut, Leibniz-Institut für Höchstfrequenztechnik (Berlin, Germany) have created just such a device, based on their previous development of an electrochemical etching method that can be used to selectively etch specific AlGaN layers. The UVB output is multiple-longitudinal-mode, but a single-mode portion of the experimental device’s area was isolated having a linewidth of 0.15 nm maximum.

“Although there is still much work to be done, especially to enable electrically driven devices, this demonstration provides an important building block for the realization of practical VCSELs covering the major part of the UV spectral range,” says Filip Hjort, a PhD student at Chalmers University of Technology. “VCSELs need two mirrors with over 99% reflectivity and these can either be made using epitaxial growth or dielectric materials. However, reflectivities high in the UVB or UVC have not been achieved using epitaxial growth, and the typical substrate-removal methods used to enable the deposition of the second dielectric mirror in blue-emitting VCSELs are not suitable for AlGaN. By employing electrochemical etching, we were able to create AlGaN membranes that we could sandwich between two highly reflective dielectric mirrors. In this way, we formed a vertical cavity that lases under optical pumping.” Reference: F. Hjort et al., ACS Photonics (2020); https://dx.doi.org/10.1021/acsphotonics.0c01382.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.