Laser diodes lead to innovations in industrial and entertainment applications

Blue laser diodes based on the indium gallium nitride (InGaN) active medium continue to become more powerful and efficient, leading to new opportunities for a wide variety of applications from medical and stage lighting to manufacturing and automotive. The introduction of blue laser diodes that are capable of several watts of optical power offer many advantages over LEDs, such as narrow angle, high power density, and superior luminance, which can result in smaller optics and form factors, longer illumination ranges, and improved coupling efficiencies into fibers and other waveguides. In addition, the use of blue laser diodes in automotive applications has helped to significantly improve illumination products in terms of optical power, electro-optical efficiency, temperature range, and lifetime.

Impact of blue laser diodes on industrial applications

High-power infrared (IR) laser diodes have been widely used in the manufacturing and automotive industries, particularly in materials processing. However, materials such as copper or gold, which are very important materials in industrial manufacturing, have a significantly higher optical absorption in the blue region compared to converted green or IR. This advantage enables emerging applications for blue laser diodes such as the welding of lithium batteries for cars and storage for renewable energy like solar panels. Furthermore, the use of more batteries in the automotive industry will create a secondary market for batteries in homes.

If IR and blue laser wavelengths are compared for copper handling, cutting, and welding, IR lasers require almost 10–15X the output power as blue lasers to get a similar processing quality. Higher metal reflectivities at IR wavelengths result in less absorption, thus requiring higher initial optical power. In addition, with blue lasers, weld shape quality is greatly improved; for example, blue lasers can create very thin foils, ensuring a smooth welding seam that translates into higher-quality products.

Blue laser diodes take center stage

One of the most exciting new developments in the lighting world is the use of high-power blue laser diodes along with red and green laser diodes to open a wide color triangle, or to be used in conjunction with phosphors to create converted white or colored lights. These converted lasers offer higher luminance compared to LEDs, enabling new types of creative lighting.

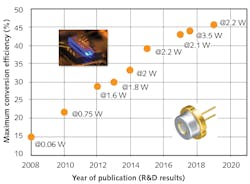

One such application is event lighting for concerts. In the past, a concert was all about the music. The lighting was usually just an afterthought—a spotlight on the lead singer here, a burst of strobe lights there. Now, laser diodes can become central to the modern concert experience in big stadiums and event halls. In particular, new blue high-power laser diodes (see Fig. 1) expand the range of options available to manufacturers of show lasers and stage spotlights, helping them to create a variety of effects that weren’t possible before.

Different options for different applications

Osram’s blue laser technology falls into three different categories:

- TO56 and TO90 can, 450 nm wavelength, hermetically sealed package, maximum optical output of 3.5 W available (product names in Figure 2; higher-power devices are on the roadmap with the target to achieve 5 W)

- Chip on submount assembly (COSA), 40 µm aperture, 4 W available, 25% higher power in the future

- Bare laser bars, 50 W optical power, 23 emitters, 7.5% fill factor, 445 nm wavelength, 38% conversion efficiency; higher-power bars on the roadmap

In terms of brightness, laser diodes offer some key advantages over LEDs. At an operating current of 2 A, an optical power of 3 W is achieved and 447 nm blue light emitted. In a typical optical system, the laser light is focused to a point only a few micrometers in diameter. The laser can be directly used as a blue light source or in combination with a special phosphor for white conversion. The luminance of the white light source is many times higher than that of a comparable LED.

The InGaN laser comes in the proven, robust TO90 package that contains only two pins for contact. Thanks to the good thermal resistance of this package, heat generated by the laser is easily dissipated from the component. This improved heat dissipation is a vital feature, as it is key for good performance and a long lifetime.

As a result, a temperature range up to 85°C and an operating voltage of <5 V are now possible, enabling small and lightweight designs for show lasers. For higher power demands and a wider temperature range, an automotive qualified version with 3.5 W optical power is available (PLPT9 450D_E A01). When compared to previously used LED light sources, the second generation of blue multimode laser diodes increases the headlight illumination range from around 250 m up to 600 m and simplifies the system design when used as the auxiliary high beam of the car.

The reliability of blue high-power laser diodes has also been significantly improved (see Fig. 3). Osram’s laser designed for automotive applications (PLPT5 450D_E A01) demonstrates more than 40,000 hours lifetime based on a 10,000-hour test. The increased temperature range paired with high performance is preferred in automotive and nonautomotive applications where high reliability is essential.Some applications require a small aperture or a low-cost emitter, as well as a high optical output power. These applications are well suited for the TO56 product. A device with 2.2 W optical output power and 35 µm aperture is available to balance cost and performance for industrial applications. Another versatile solution is ready if a small aperture of 15 µm is needed giving an optical output power of 1.6 W at a 447 nm wavelength, making it ideal for applications in which coupling into optical waveguides, fibers, and high luminance or power density is key.

Microscopy, endoscopy, and professional laser flashlights for rescue and underwater use are further examples where narrow beam and wavelength offer superior results compared to traditional illumination.

In addition to the TO can portfolio, Osram offers a COSA for better system integration. The assembly is sensitive to outside disturbances in comparison to a hermetically sealed TO can, but shows advantages in handling and performance compared to a pure die. New submount materials help to reduce thermal stress and ensure a suitable thermal bridge for improved heat dissipation.

Laser diodes making inroads

Opportunities for innovation exist if new solutions have the following characteristics:

- Higher efficiency

- Lower overall cost

- Mature technology

- Flexible, easy to set up, scalable

- Sufficient lifetime

- Environmentally friendly

- Low maintenance

Manufacturers like Osram are now making rapid and significant advancements in the 447 nm wavelength range, with blue laser diodes continuing to make large strides in terms of performance and lifetime. Increasing demand leads to higher installed capacity, resulting in higher quality and lower prices. These improvements will enable laser diodes to play an important role in even more applications and markets in the future.

Thomas Brandes | Senior Marketing Manager, Osram Opto Semiconductors

Thomas Brandes is Senior Marketing Manager at Osram Opto Semiconductors (Novi, MI).