Compact ultrafast fiber lasers enable applications in new spaces

In the 1990s, the introduction of commercial ultrafast Ti:sapphire lasers to a wide discipline of scientific researchers spawned a host of new applications. More than 20 years on, we continue to see the payoff, as new generations of compact rugged fiber-based and diode-pumped solid-state ultrafast lasers emerge, facilitating commercial applications from the doctor’s office to the production line. Perhaps the best known is the use of ultrafast laser pulses (on the order of 200 fs to 10 ps) for nonthermal materials processing, which has definitely lived up to the expectations that were anticipated years ago.1-4 Famously, professors Gérard Mourou and Donna Strickland were recognized5 with the 2018 Nobel Prize in physics for the invention of the chirped-pulse amplification (CPA) technique that forms the basis of all these higher energy platforms used for ultrafast laser processing. This article will focus on the unique aspects of compact fiber-based ultrafast laser sources and their key attributes in enabling different low-power medical and industrial applications.

Benefits of fiber-based ultrafast lasers

In parallel with the advancement of solid-state ultrafast lasers, the telecommunications boom of the 1990s also resulted in tremendous technical innovation in fiber-optic technologies with radical improvements in quality, lifetime, and price of many types of components, including pump diode lasers, couplers, beam combiners, rotators, Bragg fiber filters, modulators, detectors, and so on. Continued progress in fiber development over the past two decades has led to the commercial availability of doped double-clad fibers for multimode diode laser pumping to produce single-mode output, larger core fibers for higher power, and “designer” photonic-bandgap fibers. This has culminated in today’s high-power kilowatt-class fiber laser market for industrial manufacturing applications. While companies such as IPG Photonics have leveraged the telecommunication innovation to address the high-power industrial sector, other companies such as Calmar Laser have taken advantage of these building blocks to develop ultrafast laser platforms.

While doped-fiber architectures offer the potential of high gain and a compact design, the small fiber core diameter presents unique challenges for ultrafast optical pulses. The associated high peak powers can lead to nonlinear effects, which broaden the spectrum through self-phase modulation or induce optical damage through self-focusing. In addition, normal dispersion causes ultrafast pulses to spread in time as they propagate within the fiber.

To build a robust ultrafast fiber laser source, the pulse energies must be kept low and the chromatic dispersive and nonlinear effects must be carefully balanced in a process known as soliton pulse shaping to preserve the temporal and spectral shape of the output pulse. Since the dispersion and nonlinear effects of silica fiber are very stable over time, this pulse-shaping mechanism also ensures excellent long-term pulse stability. Further, a reliable starting mechanism is also required to induce mode-locking and provide long-term consistent performance. For simplicity, most commercial ultrafast fiber lasers favor some kind of saturable reflector as a passive mode-locking approach that requires no electronic or mechanical components. These devices increase their reflectivity by a few percent as the intensity of the circulating optical pulses increase and modulate the cavity gain to induce strong mode-locking. Calmar’s proprietary saturable reflector is packaged using a similar manufacturing approach and materials as those used for fiber-optic isolators, which ensure its robust design and long lifetime. Figure 1a shows the key components of an ultrafast fiber laser oscillator.

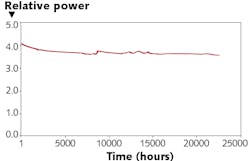

Depending upon the choice of gain fiber, these low-power ultrafast fiber lasers can provide output at a variety of wavelengths, but most commonly at 1.0 μm (ytterbium) and 1.5 μm (erbium). Figure 1b shows Calmar’s Mendocino platform, which can provide pulses as short as 50 fs and power levels up to 100 mW with repetition rates from 10 to 100 MHz, depending on the fiber cavity length. With an optimized design, the pulse shape is transform-limited with any pedestal typically at least 20 dB lower than the signal. Since pulse generation and shaping are achieved within an optical fiber that can be easily coiled and packaged into a small form factor, these sources are extremely compact and robust. With an air-cooled architecture, highly reliable active and passive telecom-derived components and a fourth-generation saturable reflector design, Mendocino systems have lifetimes of more than 20,000 hours (see Fig. 2). As a consequence, these types of fiber laser oscillators have become the industry’s preferred seed source for more-complex, higher-energy ultrafast lasers.Compact high-power architecture

Low-power ultrafast fiber lasers can also serve as the building block for higher-power fiber-based laser architectures. Figure 3a shows a diagram of the Carmel X-series, a high-power ultrafast laser source, which has an erbium-doped all-fiber CPA design. In this case, the seed laser and amplifier stages are housed in an air-cooled, rack-mountable controller. The 1.5 μm pulses are temporally stretched (chirped) through normal dispersion, then amplified and delivered through an armored fiber cable to an ultracompact laser head, where they are compressed and frequency-converted to a 780 nm output. The system is more than 100X smaller than many ultrafast Ti:sapphire lasers with similar output power levels. With pulse widths of <90 fs and power levels >1 W, the Carmel X-780 is useful for a wide range of ultrafast applications including bioimaging, two-photon microscopy, optical metrology, 3D nanoprinting, terahertz imaging, ophthalmology, and others.Today, ultrafast fiber lasers have matured to black-box devices such that OEMs and system integrators are able to seamlessly incorporate them into a wide range of instruments. Their high wall-plug efficiencies and favorable mechanical properties—for instance, rugged architecture and small form factor—coupled with instantaneous turn-on and very high stability and reliability, make them well suited to laser-based industrial and medical platforms.

Terahertz imaging/spectroscopy platform

One example is the TeraPulse Lx system from TeraView (Cambridge, England), a turnkey benchtop terahertz spectrometer and imaging system that enables the characterization of materials in the terahertz region of the electromagnetic spectrum through both reflection and transmission measurements (see Fig. 4a). At the heart of the instrument is a compact 780 nm femtosecond fiber laser that, in conjunction with a proprietary laser-gated photoconductive emitter, provides a terahertz source over a bandwidth of 60 GHz to typically 6 THz and signal-to-noise performance of >95 dB.The terahertz band is currently receiving a lot of attention as researchers explore options for 6G wireless communication technologies, even as 5G is rolling out, to achieve data rates greater than 1 Tbit/s and support the continued growth of high-bandwidth applications.6 This requires the development of a new class of devices, detectors, circuits, and so on and the characterization of materials at 6G frequencies. Figure 4b shows the advantages of a terahertz time-domain spectrometer, which is able to measure, for example, the dielectric constant of Teflon, a high-performance electrical insulator, over the ~30 GHz to 3 THz range. This should be compared with conventional vector network analysis approaches, which provide information only at discrete frequency bands.

Two-photon microscopy

In the biomedical area, JenLab (Jena, Germany) has advanced two-photon microscopy based on near-infrared (near-IR) femtosecond laser pulses for label-free high-resolution in vivo imaging of human skin, termed multiphoton tomography (MPT). The initial prototype designs for a clinical system were based upon expensive, bulky ultrafast Ti:sapphire lasers, which required water cooling and a complex articulated optical delivery arm. By moving to an ultrafast fiber laser, JenLab has introduced the multimodal MPTcompact imaging system7 (see Fig. 5a) that requires no chiller and can be freely moved around a dermatology suite, enabling real-time optical biopsies. The system has a fixed-wavelength 780 nm, 80 fs laser module that is directly integrated into the 360° measurement head, obviating the need for an optical delivery arm. The MPTcompact is currently undergoing clinical trials and offers different in vivo imaging modalities, including two-photon excited autofluorescence (AF) imaging; fluorescence lifetime imaging (FLIM) for optical metabolic imaging (OMI); second harmonic imaging (SHG) of collagen; and confocal reflection microscopy (see Fig. 5b).3D nanoprinting

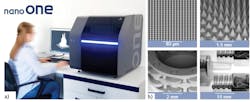

Another multiphoton technique that is used to achieve submicron resolution is two-photon polymerization (2PP). This technology allows direct writing of complex 3D objects and has already been used in a variety of applications, including the fabrication of photonic elements, scaffolds for regenerative medicine, microfluidic components, and microelectromechanical systems (MEMS). UpNano (Vienna, Austria) is a pioneer in the development of novel ultrafast high-resolution 2PP 3D printing systems and used a very compact 1 W, 780 nm ultrafast fiber laser to launch NanoOne (see Fig. 6), the first high-resolution 3D desktop printing system. Designed for manufacturing prototypes and low-volume production runs of microcomponents, this system is unlike any on the market, offering unique capabilities in terms of resolution, throughput, and fabrication scale. A high-power ultrafast fiber laser enables a desktop form factor with up to 100X higher throughput with high scanning velocities.As can be seen by the few examples presented here, there is a growing interest in leveraging low-energy ultrafast laser sources in the areas of metrology, diagnostics, and test and measurement. The good news is the performance, reliability, lifetime, and price points of today’s ultrafast fiber lasers are ready to meet the challenge of commercializing these new applications.

ACKNOWLEDGEMENTS

The author would like to thank Philip F. Taday of TeraView, Professor Karsten König of JenLab, and Denise Mandt of UpNano for their help in preparing this article.

REFERENCES

1. B. Craig, “Ultrafast pulses promise better processing of fine structures,” Laser Focus World, 34, 9 (1998).

2. J. Hecht, “Photonic Frontiers: Ultrafast laser processing: Ultrafast lasers make ultraprecise tools,” Laser Focus World, 48, 5 (2012).

3. T. Gunaratne and W. Clark, “Ultrashort pulse laser micromachining: History and future opportunities,” Industrial Laser Solutions, 29, 2 (2014).

4. M. Malinauskas et al., Light Sci. Appl., 5, e16133 (2016).

5. A. Thoss, “Nobel Prize 2018 awarded for groundbreaking inventions in the field of laser physics,” Laser Focus World, 54, 10 (2018).

6. “Towards 6G—materials and system characterization tools,” TeraView white paper, 2020.

7. K. König et al., Proc. SPIE, 11211, 112110E (Feb. 2020); doi: 10.1117/12.2542322.

Tony Lin | Founder and President, Calmar Laser

Tony Lin is founder and president of Calmar Laser (Palo Alto, CA).

![FIGURE 4. The TeraPulse Lx spectrometer and imaging system uses an ultrafast fiber laser as its driving engine (a); continuous measurements (b) of the dielectric constant of a Teflon sample over the 30 GHz to 3 THz frequency range (for comparison, vector network analysis data are shown at discrete frequency bands [6]). FIGURE 4. The TeraPulse Lx spectrometer and imaging system uses an ultrafast fiber laser as its driving engine (a); continuous measurements (b) of the dielectric constant of a Teflon sample over the 30 GHz to 3 THz frequency range (for comparison, vector network analysis data are shown at discrete frequency bands [6]).](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2021/04/2104LFW_lin_4.606cbc471eaa7.png?auto=format,compress&fit=max&q=45&w=250&width=250)

![FIGURE 5. The JenLab multimodal MPTcompact imaging system (a) and an example of in vivo multimodal multiphoton tomography (b); the top left image represents a white light view of the skin area of interest. Two- photon imaging stacks are shown in the top right image and typical en face images are shown in the bottom; autofluorescence, fluorescent lifetime imaging, second harmonic, and confocal reflectance are shown clockwise from top left [7]. FIGURE 5. The JenLab multimodal MPTcompact imaging system (a) and an example of in vivo multimodal multiphoton tomography (b); the top left image represents a white light view of the skin area of interest. Two- photon imaging stacks are shown in the top right image and typical en face images are shown in the bottom; autofluorescence, fluorescent lifetime imaging, second harmonic, and confocal reflectance are shown clockwise from top left [7].](https://img.laserfocusworld.com/files/base/ebm/lfw/image/2021/04/2104LFW_lin_5.606cbc76b1c52.png?auto=format,compress&fit=max&q=45&w=250&width=250)