Design your own ultraprecise femtosecond frequency combs

While characterizing a variety of frequency combs, Sarah Hutter and colleagues at the University of Konstanz and Toptica Photonics AG (both in Germany) recently discovered discrete operation points where the linewidth of the carrier-envelop offset (CEO) frequency drops immensely—in the most extreme case, to 700 Hz. Since this is the smallest free-running CEO linewidth ever recorded for a fiber laser, the group was highly motivated to better understand the phenomenon.

During CLEO 2023 (San Jose, CA), Hutter, a Ph.D. student, presented the group’s work, which provides clear guidelines to design free-running ultraprecise frequency combs optimized for specific measurement tasks (see video).

“Compared to active stabilization, our approach doesn’t require any additional expensive or not-easy-to-transport resources,” she says. “And any type of active stabilization has a limited locking bandwidth to reduce noise only within this particular frequency band.”

Femtosecond frequency comb design

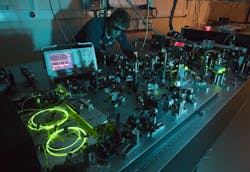

Frequency combs are ultrashort-pulse lasers, and the group based its systems on optical fibers to make them as compact, stable, and transportable as possible—without any special lab equipment.

Their system (see Fig. 1) relies on a gain medium that consists of fibers doped with the rare earth metal erbium. This enables a bandwidth centered at a wavelength of 1550 nm (193 THz), while the oscillator is based on additive-pulse modelocking.

“It’s an off-resonant modelocking method, which exploits a nonlinear phase shift due to the Kerr effect,” she explains. “The latter is a nonlinear optical effect that describes a change in refractive index proportional to the intensity of the light.”

The group’s laser cavity consists of a nonlinear amplifying loop mirror and a short free-space section, which includes adjustable polarization optics for sensitive alignment of the nonreciprocal phase bias. Since this off-resonant modelocking method doesn’t add significant dispersion, it allows the researchers to operate their laser close to zero dispersion.

A big a-ha moment struck when Hutter realized the spectral region not affected by pump noise depends on the pump power and oscillator design.

“Suddenly, all our observations made sense and could be explained—it’s an amazing feeling,” she says, likening it to sliding the last piece of a 5000-piece puzzle into place. “I’m fascinated by the possibility of actively selecting the spectral region with the narrowest comb lines. This means one frequency comb can be optimized for different applications by merely changing the pump power or fiber lengths inside the laser cavity.”

One big challenge for the group was identifying different phase noise sources affecting the comb teeth and attempting to understand how various laser parameters such as pump power, intracavity dispersion, and repetition rate influence the performance of the instruments.

“To overcome this, we did a systematic analysis of the phase noise by changing only one parameter at a time,” Hutter says. “This allowed us to set up a model and tailor-design combs featuring sharp teeth over an ultrabroadband spectrum. To characterize these ultralow-noise combs via experiments, we had to find even more stable reference lasers. And we solved this problem by locking commercial single-line lasers to an optical cavity.”

Wide range of potential applications

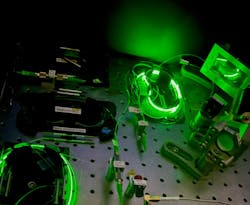

Femtosecond frequency combs are the key to high-precision measurements in science and industry. Since the group’s methods are applicable to any type of femtosecond frequency comb, it opens the door to a wide range of potential applications beyond high-precision spectroscopy, metrology, and time-domain quantum physics (see Fig. 2).

“We’d like to use these ultrastable frequency combs for applications in time-domain quantum physics,” says Hutter. “More precisely, we’re aiming for subcycle access to the quantum noise of the electromagnetic field.”

FURTHER READING

S. R. Hutter et al., Laser Photonics Rev. (Apr. 22, 2023); doi:10.1002/lpor.202200907.

About the Author

Sally Cole Johnson

Editor in Chief

Sally Cole Johnson, Laser Focus World’s editor in chief, is a science and technology journalist who specializes in physics and semiconductors.