Soliton microcombs get a big efficiency bump

A team of researchers at Chalmers University of Technology (Gothenburg, Sweden) are making soliton microcombs more efficient by outmaneuvering a fundamental problem of weak microcomb conversion efficiency between the laser and microcomb—in which only a fraction of the power of the laser beam was usable (see video).

A microcomb is essentially a ruler made of light. Laser frequency combs measure frequencies with extreme precision by sending photons into a microresonator (small cavity), where they circulate and light gets divided into a wide range of frequencies. These frequencies are precisely positioned, and a new type of light can be created via hundreds—or even thousands—of frequencies, akin to lasers beaming in unison.

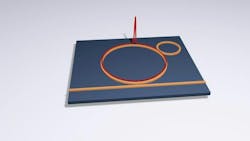

Two microresonators

A soliton microcomb is generated “by bringing a continuous-wave laser into the resonance of a high-quality microresonator,” explains Victor Torres-Company, a professor of photonics at Chalmers, who led the work. “In a standard single-cavity soliton microcomb, the soliton shifts the resonance so that the laser can’t couple efficiently into the microresonator. Our design overcomes this limitation by using an auxiliary cavity, which brings the laser pump back into resonance when the soliton is generated.”

Using two microresonators, rather than only one, forms a unique ensemble with properties that are greater than the sum of its parts (see Fig. 1). One of the resonators enables light coming from the laser to couple with the other resonator, akin to impedance matching in electronics.

“Our new microcombs have transformative potential because they make high-performance laser technology available to many more markets. For example, frequency combs could be used in LiDAR modules for autonomous driving or in GPS satellites, and environmental sensing drones, or in data centers to enable bandwidth-intensive AI apps,” Torres-Company says.

10X efficiency improvement

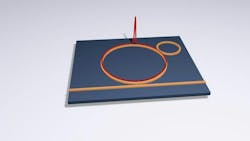

The team’s design (see Fig. 2) breaks what was previously believed to be a fundamental limit for optical conversion efficiency—by increasing the laser power of the soliton microcomb 10X, boosting its efficiency from ~1% to more than 50%.

“We actually had designs that worked but didn’t fully understand why at the beginning,” Torres-Company says. “An ‘a-ha!’ moment hit when we realized the improvement we were seeing could be explained in terms of an effective critical coupling condition.”

The next practical steps for the microcomb “involve the chip-scale development of high-performance lasers,” says Torres-Company. “From a more fundamental perspective, our new layout offers exciting physical prospects in nonlinear optics that deserve further attention.”

In good news: soliton microcombs have now reached a high level of technology maturity. But challenges remain, such as wafer-scale scalability, laser integration, packaging, and increasing power. “There are still many fundamental aspects to explore, and the journey toward deployment is still long and challenging, but I’m cautiously optimistic and excited,” says Torres-Company.

The team’s microcombs may find applications in telecommunications, microwave frequency synthesis, optical sampling, spectroscopy, and sensing. And they’ve patented this technology and launched a company, Iloomina AB, to explore wider markets.

FURTHER READING

Ó.B. Helgason et al., Nat. Photon., 17, 992–999 (2023); https://doi.org/10.1038/s41566-023-01280-3.

About the Author

Sally Cole Johnson

Editor in Chief

Sally Cole Johnson, Laser Focus World’s editor in chief, is a science and technology journalist who specializes in physics and semiconductors.