Andrew Masters and Colin Seaton

Most of the photonic elements for laser-projection applications in television, flight simulators, and cinemas are now in place.

Laser-based projection displays have long been proposed as a superior alternative to existing image-display devices like CRTs (cathode-ray tubes), flat panels, and projection systems based on lamps and LEDs. The laser’s promise has yet to become a market reality, in part because of the size, power consumption, and cost drawbacks of available visible laser technology. Technical advances are addressing these issues, however, and lasers finally appear poised to succeed in this important market. Initially, lasers will probably serve the high-value applications such as flight/ship simulators and digital cinemas. But consumer products are in active development, with introduction probably less than two years away (see www.laserfocusworld.com/articles/248114).

Superior color

Lasers have been attractive to display manufacturers because, from a theoretical and practical standpoint, they deliver a significantly better image than any other display type. Probably the biggest single advantage of lasers is their ability to cover a wider color gamut. To understand the concept of color gamut, it is first necessary to know how human color vision is defined mathematically.

Color perception arises from the way light stimulates three different types of color photosensors (called cones) in the human eye. Several models have sought to put a scientific definition on color so that it can be quantified and measured by instrumentation. Today, the most widely used of these is the CIE (Commission Internationale de l’Eclairage; see www.cie.co.at/cie) color space, which defines any given color as being a combination of three spectral curves-which somewhat mimic the response of the three types of cones-together with a background (white/black) intensity factor. For simplicity, the three color factors-x, y, z-are normalized to unity, so that any color the eye is capable of sensing is completely defined by two color factors (x and y) and a scaling (intensity) factor, L. This “color space” can be represented graphically.

A gamut is the range of colors that can be produced by a given device, and is always a subset of the total range of the human perceptual system. In a red-green-blue (RGB) display, any color is generated by mixing three primary saturated colors. If these three colors are plotted on the CIE chart, then the gamut for that device is a triangle defined by these corner points. Only colors within this gamut can be rendered (see Fig. 1).

The CRT display gamut is noticeably superior to liquid-crystal displays (LCDs), yet still only covers 60% to 70% of the NTSC (National Television Systems Committee) color gamut because of the limited color saturation (spectral purity) of the phosphor emissions. Moreover, the NTSC color gamut is substantially smaller than the eye’s total color capabilities. In contrast, the use of three lasers (at 460, 532, and 635 nm) enables coverage of 150% to 170% of the NTSC gamut. This means that laser displays deliver a wider range of vivid colors making the image far more lifelike than any existing display type (see Fig. 2).

FIGURE 2. A prototype rear-projection TV uses several watts of output from three OPS lasers emitting at 460, 532, and 635 nm.

Another color-related issue is source aging. With lamps and LEDs, output wavelengths shift as the devices age, and not necessarily at a constant rate (see page S5). This means the color reproduction of the projected image deteriorates over time. With lasers, however, output wavelength does not shift with age, and color characteristics are maintained simply by holding the laser power constant.

Brightness and contrast

Brightness is another key image parameter and is defined as the total power emitted by a source per unit solid angle per unit area. A TEM00 laser is a true point source; all the light appears to emanate from the same point in space. This means it can be perfectly collimated and focused back to a point, limited only by diffraction. In contrast, a lamp or LED emits from an extended area or volume over a large solid angle (a complete 4π steradiansin the case of a lamp). Furthermore, obtaining increased brightness from lamps or LEDs virtually always involves increasing the apparent source size. As a result, a TEM00 laser beam delivers a brightness that is multiple orders of magnitude higher than any lamp or LED.

For laser-projection displays, this translates into increased image brightness and/or resolution. Projection displays rely on a linear or two-dimensional micromirror MEMs chip. Display and chip manufacturers are focused on shrinking the dimensions of these chips, as well as the individual micromirrors, in order to reduce package size and obtain higher image resolution. To maintain image brightness as chip size decreases, the light source must be focused to a smaller spot. For any nonpoint source, reducing the focused spot size increases the cone angle (f number) of the light beam. However, both the micromirror and projection optics have limited acceptance angles, so, at some point, the system will start to throw light away. This lowers image brightness.

As a point of reference, current state-of-the-art LED-based projection television is limited to a maximum 50 in. diagonal. And, even this size requires the use of a high-gain screen containing a lens array to trade off viewing angle for brightness. A laser source avoids this problem and brightness can be scaled without limit because increasing laser power doesn’t increase the source size.

Practical implementation

In front and rear digital projectors, a light source is used to illuminate an addressable micromirror chip. Color pictures are generated by sequentially cycling through the three RGB colors using a single chip, or by combining three separate color channels. The brightness of a laser beam means that it could either be used in conjunction with a micromirror chip or in a direct-write mode, in which the beam is rastered across the display screen using galvanometer or polygon mirror(s). In reality, all current laser-display prototypes are based on micromirrors, and a combination of cost and performance issues dictate that this technology will be the first to have commercial success.

The performance issue mainly concerns scan speed. To deliver completely flicker-free images, a single-channel raster scan system would probably operate at frame rates of up to 300 frames per second (fps). This means a scan rate of up to 900 fps for each color, with each scan consisting of at least several hundred lines of pixels.

Instead, laser prototypes are based on two-dimensional micromirror displays, such as the DLP chip from Texas Instruments, or a linear micromirror display-the GLV Gated Light Valve developed by Silicon Light Machines (now licensed by Sony). In this latter configuration, a galvanometer or polygon mirror provides vertical scanning while the linear chip provides a complete row of pixels.

Laser requirements

The primary reason lasers are now poised for implementation in displays is that several key technological improvements have provided reduced power consumption, increased reliability, wider wavelength selection, higher output from a given package size, and the potential for mass production.

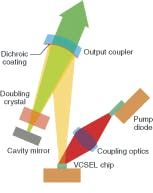

There are several solid-state approaches to generating visible continuous-wave laser light. The principal methods are edge-emitting diodes (and frequency-doubled diodes), diode-pumped solid-state (DPSS) lasers, vertical-cavity surface-emitting lasers (VCSELs), and optically pumped semiconductor (OPS) lasers. We believe that OPS lasers are the superior choice for a number of reasons. First, this is a completely scalable technology, in terms of both power and wavelength. We have demonstrated tens of watts of visible output in our R&D labs. Just as important, it is relatively straightforward to produce this power as a TEM00 beam. In terms of manufacturing, all the major components are wafer-level semiconductor devices, readily produced by proven volume production methods. Admittedly, the laser cavity itself must still be assembled but this is no more complex than assembling and aligning the electron guns and deflection coils in a CRT (see Fig. 3). The key will be robotic automation of these tasks-simply a question of investment.

In comparison, DPSS lasers are more complex and costly, while the output power of diodes and VCSELs is limited. Some manufacturers have proposed ganging diodes or VCSELs in arrays for this application. However, the use of an extended emission area lowers source brightness, negating one of the main advantages of lasers.

How much laser power will these applications require? For a 50 in. (diagonal) TV the accepted light level is 1000 lumens. This can be achieved using only 8 W of laser power: two each of green and blue, and 4 W of red. On the other hand, a 50 ft cinema screen in a low-ambient-light setting would require 50 W of total laser power, which has been experimentally demonstrated with OPS laser technology.

Outlook

While lasers clearly offer improved imaging characteristics over other display technologies, the final hurdle to their adoption is cost. We therefore expect laser technology to penetrate the higher-value applications first, where the cost can be more readily justified. These applications include digital cinema projectors and specialty displays such as flight and ship simulators, followed by large-format televisions. Flight simulators, in particular, are a near-perfect fit for lasers because lasers address one of the biggest limitations of current CRT-based systems, namely contrast, which has long limited the realism of the images and hence the entire simulated-motion experience. Then, as production volumes increase and costs correspondingly drop, laser displays will be ready to penetrate the consumer market.

ANDREW MASTERS is director of marketing and COLIN SEATON is director of business development at Coherent, Santa Clara, CA; e-mail: [email protected]; www.coherent.com