HIGH-OUTPUT LEDS: Solid-state lighting seeks a role in pictures

During the first national color television broadcast on Jan. 1, 1954—viewed on the “Model 5” prototype for the first production RCA color television—the reds and greens in the Rose Parade appeared more saturated than the orange-reds and yellow-greens that became the norm for color television decades later.1 High-brightness LED backlighting for flat-panel liquid-crystal displays (LCD) is currently under development, in hopes of meeting or exceeding the levels of color saturation that were achieved more than half a century ago.

The color gamut on the Model 5 achieved 100% of the National Television System Committee (NTSC) color standard, newly approved just one year before, because the CRT used color phosphor materials with the necessary chromaticity. Those phosphor materials, however, chosen to meet an NTSC standard based on a chromaticity diagram devised by the International Commission on Illumination (CIE) in 1931—prior to the advent of television—turned out to be too expensive for use in television sets targeted at the consumer market, which did not really take off until 10 years after that first national color broadcast.

So typical CRT performance does not offer the deeply saturated red and green hues found in nature and toward the edges of the CIE chromaticity diagram. And flat-panel displays, originally focused primarily on text and data applications, fall even shorter of that ideal, to about 75% of the NTSC standard. As flat-panel displays migrate toward consumer-entertainment applications such as displaying movies and photographs, however, the challenge of offering the richest possible viewing experience has become a focal point of industry competition.

Cold-cathode fluorescent lighting (CCFL) is the dominant technology for backlighting LCD television displays. And, as with CRTs, the color gamut is limited by the chrominance of the red-, green-, and blue-producing phosphors, which in the case of CCFLs must be highly absorbing at the 254 nm emission line of mercury (see “CCFL technology is also improving,” p. 83). In addition, CCFL technology requires a large power supply, which becomes a significant cost factor for large displays (in excess of 40 in.). LED backlighting offers the potential advantage of providing monochromatic primary color directly, eliminating dependence on phosphor materials, and eventually doing so at reduced cost.

The state of solid-state

“The proposed LED backlight solution is to use an RGB array,” according to Robert Steele, director of optoelectronics at Strategies Unlimited (Mountain View, CA). “RGB LED sources can provide higher screen brightness as well as truer color reproduction, greater image depth (especially in HDTV), and potential reduction of motion artifacts—if the LED source is pulsed with pulses shorter than the rise/fall time of the LCD. The color gamut provided by RGB LED backlights is 105% of NTSC (the color gamut for CRT TV screens), compared to 75% of NTSC for CCFL backlights. The disadvantages of the LED solution include higher cost and higher power consumption (currently) compared to CCFL.”

Manufacturers are collaborating and competing to deliver this enhanced viewing experience to a potentially huge market of television viewers. Sony (Tokyo, Japan) and Lumileds (San Jose, CA) demonstrated the viewing possibilities in introducing the first LED backlit LCD television set two years ago, and the field appears to be on the verge of major change. But a couple of fundamental technology gaps still need to be bridged before LED backlighting can be delivered at a price that is competitive for widespread home use, according to Eran Fine, CEO of Oree (Natanya, Israel).

A new generation of LEDs is needed because too many LEDs are required to provide bright enough illumination. This causes problems in terms of thermal management and power consumption, as well as cost. Currently, the cost of LED backlit LCD displays exceed that of CCFL backlighting and plasma displays by more than a factor of three. Simply increasing brightness and lowering cost would not solve the problem entirely, however, because off-the-shelf LEDs are not designed optimally for backlighting. They are designed to maximize lumens per watt or lumens per dollar, rather than maximizing the amount of light that actually enters the LCD layer. For instance, off-the-shelf LEDs tend to be dome shaped while the LCD layer presents a planar surface.

Flattening out the light

Fine noted that three groups are working together to try to solve these problems-LED companies, companies that focus on light-guiding technologies (such as Oree), and LCD providers. Oree’s focus, which Fine described last spring at the Strategies in Light conference in San Francisco, CA, is on coupling LED sources with LCD screens using planar flexible light guides (pFLGs) based on fiberoptic waveguide technology and made from a highly transmissive, multilayer, polymer-based transparent sheet (see www.laserfocusworld.com/articles/252464).

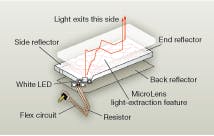

A primary advantage of this approach, Fine emphasized, is the potential for producing very thin screens. The optical path for mixing red, green, and blue to form a white backlight is confined within the surface plane of the LEDs, and no additional diffusion space is required to create a uniform field of illumination (see Fig. 1). Oree is also working on a high-brightness LED source designed for LED backlighting, but details of that project remain proprietary, along with further details concerning their flexible light guides.

A collaboration between Luminus Devices (Woburn, MA) and Global Lighting Technologies (GLT; Brecksville, OH) announced in June at the Society for Information Display conference 2006 in San Francisco, CA, is also addressing these two issues (see www.laserfocusworld.com/articles/259916). “Photonic-crystal (LED) technology from Luminus offers directional coupling out of the chip top surface at a fairly narrow angle, which for any optical system will be more efficient,” according to Chris Chinnock, projection industry and technology expert at Insight Media (Norwalk, CT). “Coupling this with the Global ability to provide even illumination over the surface from a single-edge illumination source makes this another very interesting development to watch.”The Luminus LED concept is based on the application of photonic lattices, dubbed PhlatLite, to suppress the lateral propagation of photons and essentially deliver more light in a narrower, collimated beam that is more readily collected and delivered to its target. PhlatLight devices can also be made in any shape and size, which enables them to be precisely tailored for a particular application, as well as to optimize thermal and electrical power management.

The GLT MicroLens is a pixel-based light extraction technology in which up to 180,000 micro-optical elements per square inch are molded directly into a light guide, essentially providing lens arrays to spread and project light from a row of LEDs or a single LED at one edge of a backlight uniformly across the entire backlight surface, thereby also reducing the number of LEDs required (see Fig. 2).

Efforts by Luminus, GLT, and Oree have been publicized, even though technical details remain proprietary. But there’s a lot more development work going on in the industry that is totally under the radar, according to Chinnock, who projects, a bit more aggressively than most, that cost-competitive LED backlit LCD televisions will hit the market within the next two years.

Not quite a ‘holy grail’

While meeting or exceeding 100% of the NTSC color gamut is currently the mark to shoot for, it has already fallen far short of “holy grail” status. According to Wikipedia, video professionals and television engineers have been heard to joke, partially because of color imbalances introduced by cabling systems, that NTSC should really stand for “Never The Same Color” or “Never Twice the Same Color.”2LED backlighting offers a number of potential advantages for broadening color gamut. But it also brings color-stability challenges that include the difficulty of maintaining color uniformity when there are different degradation rates for each LED in an array, shifting of emission wavelengths with temperature variation, panel-to-panel variation in LED color, and part-to-part variability (tight binning used to address part variability also adds to cost).

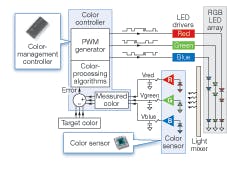

To address these issues Avago Technologies (San Jose, CA and Penang, Malaysia) has developed a pulse-width-modulation (PWM) closed-loop feedback system for illumination and color management (ICM) that samples color balance 100 times per second and not only maintains color uniformity, but also simplifies RGB LED implementation and allows user control of color palette (see Fig. 3 and www.laserfocusworld.com/articles/252464).

Despite the potential for high-brightness LEDs to significantly improve the television color gamut and viewing experience, and the impressive and highly competitive technologies that have been arrayed to make that happen, Steele cautions that the potential market is just as complicated as it is huge. In order for any new approach to succeed, he said, “the consumer has to see some value.”

REFERENCES

1. www.novia.net/~ereitan/rose_parade.html

2. http://en.wikipedia.org/wiki/NTSC

CCFL technology is also improving

Light-emitting-diode manufacturers aiming to replace CCFL backlights must chase a moving target, according to Robert Steele at Strategies Unlimited (Mountain View, CA). New developments on the CCFL front include external-electrode fluorescent lamps-which reduce power-supply costs by enabling several lamps to operate off a single power supply-flat fluorescent lamps, and wide-color-gamut (WCG) CCFL. Flat fluorescent lamps use a xenon rather than mercury discharge, as well as a low-voltage power supply. They offer a slightly wider color gamut than CCFL (80% of NTSC), and a flat emitting surface with the same size and profile as the LCD panel that they backlight. The WCG CCFL color gamut approaches 95% of NTSC by adjusting the phosphor mix or alternatively by including more than three primaries through creative use of color filters and color processing algorithms, to cover more of the chromaticity diagram. In addition to approaching LED levels of color-gamut performance, the latter approach also steals thunder from the LED potential for incorporating a broader palette of chips than just three primaries in the backlight mix.

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.