Sources For Illumination: White-light LEDs range from ‘warm’ to ‘cool’

IAN ASHDOWN, MARC SALSBURY, INGO SPEIER, AND BRENT YORK

Over the past 100 years, architectural lighting has progressed from incandescent lamps to fluorescent and high-intensity-discharge (HID) arc lamps. The past five years have seen the introduction of a new and more energy-efficient light source: the high-flux light-emitting diode (LED). Since they were introduced as indicator lamps in the 1960s, LEDs have become increasingly competitive with incandescent and fluorescent lamps for architectural lighting applications.

Currently, most of these applications involve red/green/blue (RGB) color-changing light fixtures (or “luminaires”). However, the long-term goal is to replace most incandescent, fluorescent, and possibly HID lamps with LEDs. It has been estimated that this solid-state lighting will reduce global energy consumption for lighting by as much as 50% by 2025.1 To accomplish this, we will need energy-efficient and inexpensive white-light LEDs.

Defining and generating white light

The color white is ordinarily defined as simply “the absence of color.” In terms of color science, however, white light is visible light that we perceive as having the same color as an incandescent blackbody with a color temperature ranging from roughly 2500 K to 7500 K.2 This is why we (paradoxically) refer to fluorescent lamps with a color temperature of 3000 K as “warm white,” and fluorescents with a color temperature of 4100 K as “cool white.”

Controllable color temperature is a feature unique to solid-state lighting. People who have seen luminaires with this feature learn that lamp-color temperature strongly influences the mood of a room or illuminated architectural space. It is probably this feature that will initially sell solid-state lighting into the residential and retail lighting markets; energy savings and extended lifetime will be secondary considerations.

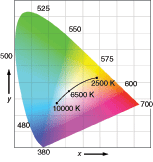

We can generate all but the most saturated colors using an additive combination of red, green, and blue light. The full gamut of colors are plotted on the CIE 1931 chromaticity diagram, where the chromaticity of white light over the range of color temperatures is referred to as the “Planckian” (or “blackbody”) locus (see Fig. 2).2, 3The chromaticity diagram represents a linear color space in that we can mix any two colors with chromaticity coordinates {x1,y1} and {x2,y2} and mixture weights w1 + w2 = 1, resulting in a third color whose chromaticity {x3,y3} = {w1x1 + w2x2, w1y1 + w2y2} lies on a straight line between the first two colors.

Two major approaches

By themselves, most semiconductor LEDs are narrowband emitters with spectral widths (full width at half maximum) of 20 to 35 nm. LEDs based on aluminum indium gallium nitride (AlInGaN) materials have peak wavelengths ranging from near-UV to green, while LEDs based on aluminum indium gallium phosphide materials have peak wavelengths ranging from amber to red.5

We perceive these narrowband emissions as saturated colors and can therefore generate white light with any color temperature by combining appropriate ratios of light emitted by a multicolor cluster of red, green, and blue LEDs and using nonimaging optics to thoroughly mix the emissions.

A second approach to generating white light is to coat blue-emitting AlInGaN LED dies with one or more phosphors, such as cerium-doped yttrium aluminum garnet (YAG), to downconvert a portion of the emitted light to wideband yellow light. The resultant phosphor-coated LEDs (referred to as “pcLEDs”) emit a mixture of blue and yellow light, which we perceive as “cool” white light with color temperatures ranging from 4500 K to 10000 K. (Color temperatures in excess of 6500 K are generally considered too bluish for architectural lighting.)

In the past few years, LED manufacturers have developed or licensed proprietary red-emitting phosphors which, usually in combination with YAG phosphors, generate “warm white” light with color temperatures ranging from 2850 K to 3800 K. We can thus generate white light with any color temperature by combining appropriate ratios of light emitted by white and warm white pcLEDs.

Seeing white

Given the chromaticity of any color on the CIE 1931 chromaticity diagram, there is a surrounding “MacAdam ellipse” that indicates the limits of our ability to distinguish the color from neighboring colors.4 The ellipse parameters vary with chromaticity, but a useful approximation is that the width of a MacAdam ellipse centered anywhere on the Planckian locus is equal to one microreciprocal Kelvin, or “mirek.” Thus, for example, we can just distinguish lamps with a color temperature difference of 200 K (106/5000) at 5000 K.

The chromaticity variation of fluorescent lamps is mandated to be within four MacAdam ellipses (that is, four times the size) of the target chromaticity for each industry-standard color temperature.6 Current manufacturing techniques allow pcLEDs to achieve this requirement, but only with careful binning of the LEDs by chromaticity—a production run of pcLEDs typically has considerably larger variation.

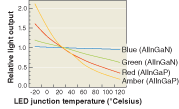

It is easier to meet lighting-industry expectations for white-light sources with multicolor LED clusters; however, it can be difficult to maintain a specific chromaticity. Each LED color exhibits its own thermal dependencies, and LED junction temperatures (effectively the temperature of the semiconductor die) can range from ambient temperature to 120°C or more if the luminaire is dimmable (see Fig. 3). Even slight changes in the emitted RGB light ratios due to temperature changes can result in perceptible color shifts.7A similar problem occurs with pcLEDs, although to a lesser extent. It arises in part because the peak wavelength of blue-emitting LEDs shifts with changes in junction temperature, and because the phosphor conversion efficiencies are temperature-dependent.7 (Even without thermal issues, the distance between the Planckian locus and the straight line between white and warm-white LEDs can exceed four MacAdam ellipses.)

Correcting for thermal drift

There are, however, solutions to these thermal issues. For multicolor LED clusters, optical and thermal feedback can be used to maintain the chromaticity to within one MacAdam ellipse, even when the luminaire is being dimmed and the LED junction temperatures are changing rapidly. With careful modeling and characterization of the LEDs, it is also possible to use a thermal feedforward circuit and still maintain the light-source chromaticity within acceptable limits.

Maintaining the chromaticity of white and warm-white pcLED combinations is more difficult because their individual chromaticities are fixed. However, they can be augmented with amber LEDs to adjust the chromaticity and maintain it within required limits. Alternatively, warm-white LEDs can be augmented with a combination of blue and green LEDs for the same purpose. As with multicolor LED clusters, however, optical and thermal feedback is required to maintain the light source chromaticity.

Another consideration is aging of the LEDs and phosphors. The luminous-flux output of LEDs decreases continually over their lifetime, while phosphors are subject to short-wavelength radiation damage and overheating, resulting in long-term color shifts. Fortunately, these can be compensated for with optical feedback.

Other issues

Other issues include color rendering and energy efficiency. Phosphor-coated LEDs generally offer better color-rendering indices than RGB LED clusters. However, the difference becomes less important when amber LEDs are included in the cluster. (It should also be noted that the issue of applying the CIE Color-Rendering Index to white-light LEDs is contentious, and that improved metrics are under consideration.8

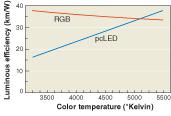

Finally, the phosphors currently used in warm-white LEDs are comparatively inefficient. As a result, RGB LED clusters are considerably more efficient than pcLEDs for low-color-temperature applications (see Fig. 4). This situation may change, however, if more-efficient and stable red-emitting phosphors can be developed.Outlook

Choosing between multicolor LED clusters and pcLED combinations involves numerous considerations, and is ultimately application-dependent. White and warm-white pcLEDs are useful when long-term color consistency and energy efficiency are not particularly important, or when accurate color rendering is required. LED clusters are useful when color consistency between luminaires and energy efficiency at low color temperatures are important.

The bottom line, however, is that research and development of high-flux LEDs is still very active. As only two examples, white-light LEDs can be fabricated from zinc oxide materials, and quantum-dot phosphors can potentially outperform the current generation of rare-earth phosphors used for pcLEDs. It is still too early to predict which approach to white-light LEDs will prevail for the next generation of architectural light sources.

REFERENCES

1. OIDA. Light Emitting Diodes (LEDs) for General Illumination. Optoelectronics Industry Development Association (2002).

2. D. Malacara, Color Vision and Colorimetry, SPIE Press (2002).

3. M. Rea ed., IESNA Lighting Handbook, Illuminating Engineering Society of North America (2000).4. G. Wyszecki, et al., Color Science: Concepts and Methods, Quantitative Data, and Formulae, Wiley-Interscience (2000).

5. A. Zukauskas, et al. Introduction to Solid-State Lighting, Wiley-Interscience (2002).

6. ANSLG. Specifications for the Chromaticity of Fluorescent Lamps, ANSI C78.376-2001. National Electrical Manufacturers Association (2001).

7. M. Dyble et al., Proc. Solid State Lighting V, SPIE 5941, 291 (2005).

8. W. Davis et al., Proc. Solid State Lighting V, SPIE 5941, 283 (2005).

IAN ASHDOWN is a senior research scientist, MARC SALSBURY and INGO SPEIER are research scientists, and BRENT YORK is chief technology officer at TIR Systems Limited, 7700 Riverfront Gate, Burnaby, BC, Canada V5J 5M4; e-mail: [email protected]; www.tirsys.com