Technical hurdles loom on the path to general illumination

Development of efficient green and ultraviolet emitters and thermal management of LED sources will be important concerns.

David Nicol, Nola Li, and Ian Ferguson

Advanced lighting based on solid-state technology will eventually replace conventional incandescent and fluorescent sources in many general-illumination applications. It has already achieved success in niche markets like signage and displays, where the attributes of LEDs make for a good fit. Significant technical hurdles remain, however, before solid-state lighting will be accepted for general illumination (see “LED vs. halogen: An MR16 case study,” p. S4).

General illumination requires high-quality white light that has a desired correlated color temperature (CCT, dependent on culture and geographic region) and that is perceived to render all colors well. Typically, broadband emissions, such as daylight or incandescent light, render colors well and can have a suitable CCT. Thus, broadband solid-state light sources or at least wide-range LED emission spectra may be desired. In some cases a tunable CCT may be required to adjust to the intended function of an illuminated area.

Increases in efficiency, lifetime, total luminous flux, and reliability are also necessary for solid-state lighting to be a successful general-illumination source. The development of efficient green emitters will be very important. Without an efficient green emitter highly efficient white-light sources are difficult to create. On the other hand, an efficient UV emitter may be a solution to pump highly efficient phosphors to create white light. Thermal management is significant because it affects many metrics. In addition, thermal-management methods must be coordinated from initial chip design through lighting infrastructure development.

Standard metrics will also be needed to classify devices for consumers, thereby minimizing potential complications with buying and specifying the novel sources. Existing standards may not be suitable for LED-based sources, although new standards will have to be comparable to the conventional ones to gain acceptance by lighting designers. And manufacturers must be comfortable with the standards to maximize device performance. Standards for specifying solid-state light sources will, therefore, require a convergence of inputs from LED manufacturers, fixture manufacturers, and lighting designers.

The green gap

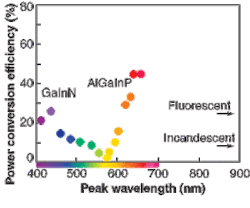

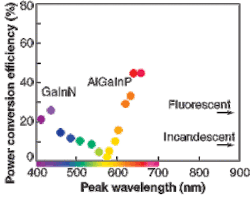

Efficient green emitters at 555 nm are required for several solid-state lighting applications, including Digital Light Processing (DLP) projectors, color displays, and controllable red/green/blue (RGB) white light. A “green gap,” however, falls between the two LED device material systems-aluminum gallium indium phosphide (AlGaInP) and gallium indium nitride (GaInN)-that are used to produce visible-spectrum solid-state light sources (see Fig. 1).1

Two physical mechanisms are responsible for the existence of this gap. First, as AlGaInP devices are tuned to emit shorter-wavelength light, the material becomes an indirect semiconductor, diminishing light output. Second, in the GaInN device, the mechanism that contributes to decreasing emission efficiency is the high dislocation density of the material that leads to strong nonradiative recombination. Blue devices have high efficiency because compositional fluctuations in the GaInN active region of the LED aid radiative recombination in the material. However, as the GaInN alloy composition is tuned to produce green emission, the mechanism for strong emission loses effectiveness.

It is unlikely that indirect-bandgap AlGaInP will ever produce good emitters around 555 nm because the indirect bandgap is an intrinsic property of the material. It is more likely that a solution will be found for GaInN given the high dislocation density resulting from growth on non-native substrates such as sapphire. Lattice-matched epitaxy on native gallium nitride (GaN) or other substrate technologies such as zinc oxide (ZnO) are likely to offer a solution.

UV sources

Pumped phosphor devices offer another method for producing solid-state white light. First-generation devices use a blue LED with a yellow phosphor, but the correlated color temperature of these sources is generally higher than desired for general illumination. Ultraviolet pumped phosphor devices are good candidates for next-generation solid-state lighting sources because of the wider range of phosphors that can be fluoresced with UV light, and because they can be manufactured more easily than RGB white-light devices.

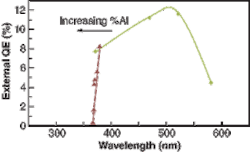

In the AlGaN material system used for UV devices, however, increasing aluminum to achieve shorter wavelengths results in a reduction of light output (see Fig. 2). High-aluminum-concentration devices show poor crystallinity compared to GaN. Consequently, radiative recombination reduces and the material becomes more resistive. New growth schemes and other novel solutions are required to solve this problem.

Thermal issues

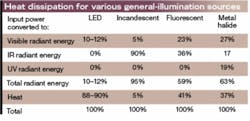

Thermal management is crucial because solid-state light sources give off heat differently than conventional general-illumination sources (see table).2 If the heat is not effectively removed, it could damage the device and lead to reduced illumination quality or catastrophic failure. Solid-state sources are unlikely to ever become suitable for existing Edison bulb sockets, which were not designed with mechanisms to counter direct heating from the source because incandescent sources dissipate most of their heat through infrared (IR) radiation.

Thus, a thermal-management solution is required for solid-state light sources used in general illumination, whether it is part of the emissive device or part of the fixture or lighting infrastructure. Thermal management is likely to be a concern at all of these levels of design because heat is created at the chip level and must be dissipated at the infrastructure level.

Of course, heat-management concerns will continue to grow as chips are driven at higher current densities to compete with and replace conventional general illumination sources. Thermal management affects lifetime to catastrophic failure, performance over lifetime, phosphor lifetime, spectral power distribution, and other characteristics of the solid-state lighting device.

Cost and standards

Cost, which is the foremost driver of success or failure for general illumination sources, has two components: initial cost and operating cost. Although the operating costs of solid-state lighting can be low because of long source life and potentially high efficiency, the initial cost may be high enough to prevent consumers from investing in the products for general illumination in the first place.

The total cost of a solid-state light source is affected by device efficiency, material, installation, and fixture costs (materials and thermal management), among other factors. Improvements are possible in each cost area. But simply improving cost will not ensure the success of solid-state lighting because illumination quality and technology standards also pose critical issues.

Currently, most solid-state light sources have a low color-rendering index (CRI) and undesirable CCT. These problems are being addressed, however, and are not expected to pose a major problem. Nonetheless, industry-wide quality specification standards are needed for solid-state light to facilitate higher-quality sources. These standards may differ from those developed for conventional light sources, but must be similar enough to allow easy adoption by industry participants.❏

REFERENCES

1. M.G. Craford, Solid State Lighting: Technology Status, Trends and Remaining Challenges, Workshop on Energy Efficient Advanced Lighting at Georgia Institute of Technology (Feb. 19, 2002).

2. K. Leadford, Solid State Lighting and General Illumination, Workshop on Energy Efficient Advanced Lighting at Georgia Institute of Technology (Feb. 19, 2002).

DAVID NICOL and NOLA LI are Ph.D. students, and IAN FERGUSON is a professor at the School of Electrical and Computer Engineering and founder of the Focused Research Program on Next Generation Lighting at the Georgia Institute of Technology, Atlanta, GA 30332; e-mail: [email protected]; www.ssl.gatech.edu.

Quest continues for solid-state general illumination

General illumination is often spoken of as the “holy grail” of solid-state lighting technology, and as with any quest, there are dragons that need slaying. In this case the dragons might be thought of as technical hurdles to overcome, which are described in the first article, written by David Nicol, Nola Li, and Ian Ferguson of Georgia Tech .

Quests also invariably include numerous adventures along the way, which Contributing Editor Kathy Kincade covers in the second article on current and emerging white-light applications for solid-state illumination.

Questing heros are also always presented with alternate paths from which to choose, and in this issue of Optoelectronics World, I look at one potential path to solid-state white light produced cheaply and efficiently: phosphors made from semiconductor nanocrystals, or quantum dots. That path appears to offer promise, but still requires a great deal of work before anyone will know for sure.

Hassaun A. Jones-Bey

Senior Editor

LED vs. halogen: An MR16 case study

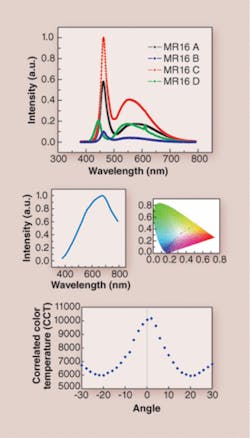

Four LED MR16 lamps were purchased from different manufacturers and compared to a conventional halogen MR16 lamp. The spectral distributions of LEDs compared to halogen were radically different, as shown in spectral intensity curves for each LED configuration (A through D, top) and the halogen spectral-intensity plot (center). Strong, narrow peaks, from blue LEDs, were observed between 440 and 460 nm, and shorter, broad peaks, from yellow phosphors, appeared at about 570 nm.

Color-rendering indices (CRIs) for LEDs A, C, and D, and for halogen were 81, 82, 68, and 95, respectively; CCTs were 7900 K, 6800 K, 5000 K, and 3260 K, respectively. CRI and CCT data were not available for LED configuration B. Configuration A and C had very high CCTs that would have been undesirable for general illumination. Only D exhibited a CCT close to natural sunlight. However, D also had a CRI that was much too low to compete with existing products.

The graph of CCT vs. angle for LED configuration C (bottom) showed similar characteristics to the other LED devices. The eye is capable of detecting changes of 50 to 100 K in CCT.1 And CCT varies by more than 4000 K for MR16 C, or 40 to 80 times the minimum variation detectable by the human eye, which is typically not good for illumination. The halogen lamp, in contrast, had a maximum variation in CCT vs. viewing angle of 111 K.

The LED-based MR16s exhibited power efficiency comparable to the halogen device. A, B, C, and D dissipated 0.7, 0.1, 1.0, and 2.0 W, respectively, with efficiencies of 15, 19, 24, and 4.8 lm/W, respectively, which translates into low lumen output for these devices. However, the MR16 devices have the advantage of extremely long lifetimes: both C and D promise 100,000 hours of useful life.

The data suggest that LED-based MR16s still have significant technical issues to overcome before a suitable general-illumination device is available. Strong green emission and red emission would help to raise the CRI and give more CCT control for these devices. Alternatively, UV-pumped phosphor devices could offer broadband emission with increased CRI and desirable CCT. Better thermal management would allow for higher flux chips to be used in these devices to increase overall total luminous flux and increase reliability.

Finally, the specifications for some of these devices differed greatly compared to the measured values, and there was no specification for angular variation of CCT, which is an important factor in general illumination. LED-based MR16s do show the potential for a solid-state replacement of conventional general illumination devices, once technical issues are addressed.

REFERENCES

1. K.N. Leibovic, Science of Vision. New York: Springer-Verlag, 1990.