Green thin-disk laser emits 400 W CW in a near-fundamental mode

The need for high-power green laser sources for welding copper has driven the development of frequency-doubled disk and fiber lasers emitting in the 515–532 nm spectral region. Achieving both high power and single-mode operation for these lasers has been difficult. Now, scientists at the Institut für Strahlwerkzeuge, Universität Stuttgart (Stuttgart, Germany) have created a continuous-wave (CW) thin-disk laser that uses intracavity second-harmonic generation to reach an output power of 403 W at a 515 nm wavelength with an almost diffraction-limited beam. An intracavity grating waveguide mirror was used to both wavelength-stabilize and spectrally narrow the laser, achieving a doubling efficiency of 40.7% with respect to the laser pump power.

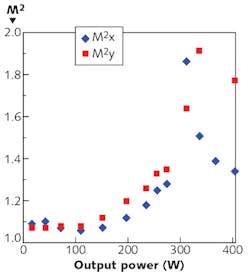

The researchers built their laser around a 130-μm-thick, 15-mm-diameter, 10 at. % ytterbium-doped YAG (Yb:YAG) disk provided by Trumpf (Ditzingen, Germany), which was mounted on a diamond heat sink and diode-pumped at a 969 nm wavelength. The light was frequency-doubled by a 15 × 4 × 4 mm lithium triborate (LBO) crystal placed in the cavity. The beam exhibited a beam quality (m2) of 1.35 or less up to a power of 300 W, at which point there was an abrupt jump in m2 to a maximum of about 1.9. The researchers attribute this to a power-dependent, thermally induced change of the critical phase-matching angle. Readjusting the position of the crystal at powers above 300 W improved beam quality, but the LBO crystal was not large enough to allow the full angular tuning range needed for optimum use of the fundamental-frequency light. Using a larger crystal or an improved crystal oven should correct this problem, say the researchers. Reference: S. Piehler et al., Opt. Lett., 41, 1 (Jan. 1, 2016).

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.