Photonic Frontiers: Color Measurement, Light Sources, and Vision: LED lighting makes new demands on color measurement

New light sources and studies of human vision are forcing an ongoing rethink of color measurement and standards. The goal is to better quantify how we see color, but that's a slippery matter. It depends on the spectrum of the illuminating light, the reflective spectrum of the object being viewed, and the perception of the human eye, and that last factor is inherently subjective because it relies on our senses.

The basic concepts of color measurement were codified decades ago by the International Commission on Illumination, known from its French acronym as CIE. The prevalent light sources at the time were the sun and incandescent lamps, leading to the establishment of concepts such as color temperature, which measures the color of illuminating light by comparison to continuous blackbody spectra at various temperatures. That was an approximation even at the time, and early standards had to be adjusted for fluorescent lamps. Now, color standards are being adjusted to cover solid-state LED lighting.

The blue-rich spectrum of LEDs used in street lighting also is challenging another set of standards. Specifications for road illumination are based on outdated assumptions about the transition between photopic (day) vision and scotopic (night) vision.

Color temperature

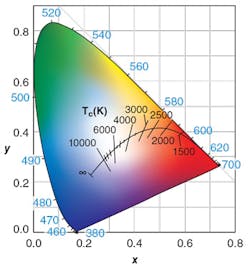

The simplest way to measure light source color is to compare the source spectrum to that of blackbody sources. This yields a correlated color temperature, a single number defined as the temperature (in degrees Kelvin) of a blackbody source with a balance of color closest to the source spectrum. This number typically is used to specify color of LED bulbs. A color temperature of 2700°K means the bulb has a red-rich or "warm" spectrum usually preferred for relaxing interior lighting. A color temperature of 3000°K is more yellowish and may be called "warm white." Workplaces usually are illuminated with "cool white" light at color temperatures around 4000°K. Some high-blue LED bulbs have color temperatures even higher than the 5700°K of the sun, and look bluish to the eye.

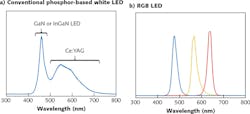

The simplicity of the color temperature scale is attractive for consumer products, but it is inherently imprecise because LED emission is far from a blackbody curve. Fixed-color consumer LED sources typically combine light from a bright-blue LED, with phosphors emitting in a broad band centered on the yellow. Using more of the blue light to excite the phosphors reduces the color temperature. Red phosphors or red LEDs may be added to produce even lower color temperatures. Tunable-color bulbs combine light from red, green, and blue LEDs—changing their relative outputs changes the color temperature (see Fig. 1).

The lighting industry uses more precise measurements and standards to assure that their products look good to the eye. Usually, that means they emit a blend of colors that looks white to the eye, and that blend depends on the color temperature. A key tool in achieving that goal is to specify color objectively in terms of chromaticity, which is based on two independent quantities—hue and saturation (or chroma)—that are plotted in a two-dimensional "chromaticity space" (see Fig. 2). Chromaticity spaces also plot the color mixtures in blackbody spectra and lines crossing the blackbody curve where the correlated color temperature is constant.Standards continue to evolve to keep up with the technology. The American National Standards Institute (ANSI) published its first draft of a solid-state lighting chromaticity standard in 2008, with a final version in 2010, and then issued revised versions in 2013 and 2015. Those changes extended the specified white range to 2200 to 6500°K.1 Now, an ad hoc group is working on further refinements. A key issue, writes LED lighting consultant Jianzhong Jiao, is accommodating differences revealed by recent research between what people perceive as white and the shade that they prefer for white light.2

Color rendering and metamers

Most objects are reflective, and we usually think of their color as being inherent to the object. But the actual spectrum of light reflected is a product of the spectrum of the light source and the object's reflectivity. We often don't notice the difference when changing light sources because we remember objects as having particular colors, and don't notice the difference unless we compare different sources side by side.

This effect is called color rendering and the impact of using a particular light source is measured by its color rendering index (CRI), which compares the color differences between objects illuminated by the light source and a blackbody reference source such as an incandescent bulb. If the colors appear exactly the same, the CRI is 100. Typical LED ratings are about 80, which generally is considered acceptable. But the value of this simple numerical scale has been called into question because of the complexity of lighting issues.

One issue is that the eye can perceive light sources with different spectra as the same color, an effect called metamerism. It arises from the way that the brain balances the responses of the eye's red, green, and blue receptors to determine the hue or color of light. Reflection from colored objects changes spectra, and may leave them looking different to the eye.

A particular issue with most LED lamps is that using a strong but narrow blue emission line to pump phosphors reduces CRI to about 80 because it produces virtually no light at shorter violet wavelengths or longer blue-green wavelengths. Soraa (Fremont, CA) produces solid-state lamps that emit across the whole visible spectrum by using a violet LED and a different blend of phosphors to produce a more uniform spectrum with a CRI of 95. But that better color rendering comes at the cost of lower efficiency, and Shuji Nakamura, co-director of the solid-state lighting center at the University of California at Santa Barbara and a founder of Soraa, has said that increasing CRI from 80 to 90 reduces lumens generated per watt by 20%.3

Color-rendering standards are particularly problematic for bulbs that generate white light by mixing the light from narrow-band and broadband LEDs. Although objects reflecting that blend of light can look good to the eye, they rate low on the CRI scale, says Michael Brill of Datacolor (Lawrenceville, NJ). He and others have urged changing color rendering standards to address the problem. Committees of the CIE, Illumination Engineering Society (IES), and the Global Lighting Association are working on such standards.

Mesopic vision and highway illumination

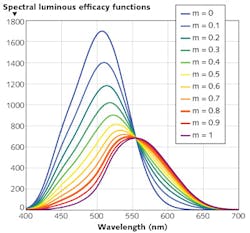

The use of LEDs for street lighting has raised another set of color measurement issues—how to best measure human visual response at intensities between daylight and full darkness. During the day, the red, green, and blue cones in our retinas respond to light between 400 and 700 nm, our photopic vision. At night, rods respond to lower light levels, but only at 400 to 600 nm, giving us scotopic vision, which is well matched to the bluish spectrum of moonlight at a color temperature of about 4100°K. Vision researchers have known for a century that the two systems operate together at intermediate light levels from 0.005 to 5 candelas per square meter, and now call our visual response in that twilight region mesopic vision. Figure 3 shows the luminous efficacy functions for varying levels of dark adaptation, from fully dark adapted at m=0 to daylight adapted at m=1.Standards for roadway and parking-lot illumination set by the Illumination Engineering Society (IES) have long been based on the human photopic response. That simple criterion was well matched to the spectrum of most street lamps, including high-pressure sodium lamps, which are widely used because of their relatively high efficiency, whitish-orange color, and CRI of 85.

Now, the U.S. Department of Energy is pushing replacement of those lamps with more-efficient LED bulbs, and is pushing LED lamps with color temperatures of 4000 °K or higher because of their higher efficiency than those with lower color temperatures widely used indoors. The color looks like moonlight, but the LED lamp intensity on the street at the levels recommended by the IES road standard looks much brighter than that from a high-pressure sodium lamp.

The extra brightness comes from the eye's response in the mesopic vision zone, which is much stronger to the bluish LED spectrum than to the orangish light from high-pressure sodium. Tests conducted in Seattle by lighting consultants Clanton & Associates (Boulder, CO) found that drivers could detect potential hazards farther away in areas with LED lamps than in those lit with sodium lamps—and that dimming the lamps to half the level recommended by IES standards did not reduce detection distances significantly.4 So adopting new roadway illumination standards based on mesopic vision could save even more energy by reducing light levels, without impairing safety and with a reduction in environmental impact.

Outlook

We have more to learn about the impact of LED lighting on color measurement, standards, and illumination. Color is notoriously subjective and hard to quantify. Issues such as the environmental impact of street lighting and the illumination needed for safe driving need further research. We also need to study tradeoffs carefully. But revising standards and careful management can help us extend the benefits of solid-state lighting beyond simply improving energy efficiency.

REFERENCES

1. J. Jiao, "ANSI works to update the solid-state lighting standard for chromaticity," LEDs Magazine, 12, 2, 47 (Feb. 2015).

2. J. Jiao, "ANSI continues advancements on SSL chromaticity standard," LEDs Magazine, 12, 11, 41–43 (Nov. 2015).

3. M. Wright, "Lighting coalition asks EPA to lower Energy Star efficacy specs for high CRI lamps," LEDs Magazine online (Jan. 2013); http://bit.ly/1OAt8IE.

4. N. Clanton, "Seattle LED adaptive lighting study," Northwest Energy Efficiency Alliance (May 29, 2014); http://bit.ly/1OAtgYO.

Jeff Hecht | Contributing Editor

Jeff Hecht is a regular contributing editor to Laser Focus World and has been covering the laser industry for 35 years. A prolific book author, Jeff's published works include “Understanding Fiber Optics,” “Understanding Lasers,” “The Laser Guidebook,” and “Beam Weapons: The Next Arms Race.” He also has written books on the histories of lasers and fiber optics, including “City of Light: The Story of Fiber Optics,” and “Beam: The Race to Make the Laser.” Find out more at jeffhecht.com.