Mid-IR Lasers: Two lasers in one: 'Yin-yang' mid-IR laser has two synchronized channels

Fiber lasers have an increasing advantage over other laser types because of their highly integrated design and, as a consequence, compact size, lower cost, and excellent robustness against environmental exposure. Pulsed operation of fiber lasers at 2 μm and other mid-infrared (mid-IR) wavelengths is desirable for various applications, including lidar, molecular studies, optical communication, atmospheric monitoring, medical diagnostics, and surgical applications.

Researchers from Aston University (Birmingham, England) and Shanghai University (China) have recently demonstrated a modified ring fiber laser in a "yin-yang" configuration that boasts an isolator-free design.1

Yin-yang

Fiber-optic components such as optical isolators that operate in the mid-IR region are expensive and complicated to manufacture. But an alternative design using a yin-yang configuration and a single-wall carbon nanotube (SWNT) saturable absorber overcomes the fundamental limits of conventional fiber lasers, and provides scaling to higher output powers and/or pulse energies.

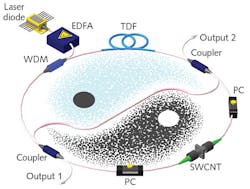

The laser uses thulium-doped fiber as the gain medium (see figure). Two standard fused couplers form hybrid nonlinear loop mirrors when spliced together. When incorporating a carbon nanotube polymer composite as a saturable absorber, the laser can operate in the Q-switched regime, generating submicrosecond pulses with maximum output power of 197 mW and pulse energy of 1.7 μJ. The researchers say this is the highest power yet from a thulium-doped fiber laser Q-switched with a CNT polymer (sandwiched between fiber ferrules).

The application of polymer-embedded CNT saturable absorbers was originally thought to be detrimental to a fiber laser design because of its low thermal damage threshold when it interacts with the most-intensive central part of the optical field. However, the laser setup was constructed in such a way that the nonlinear loop mirrors act as additional saturable absorbers based on the nonlinear optical Kerr effect, therefore stabilizing pulsed operation at high powers.

The yin-yang cavity consists of two coupled nonlinear fiber loop mirrors, in which one fiber loop acts as a feedback mechanism for the second fiber loop. In the experiment, the researchers used a set of fiber couplers to form the nonlinear mirrors. Varying the coupling ratios directly alters the total power distribution within the cavity, and modifies its gain and pulse dynamics behavior. As a result, the design allows for the opportunity to predefine the operation direction. By tailoring the proper coupling ratios, self-maintaining laser propagation occurs in a single direction. This effectively eliminates the need for a high-cost optical isolator device in the mid-IR region. Moreover, the yin-yang configuration is easily extended to other wavelengths for which optical isolators are complicated and expensive.

The other value of adjustable coupling ratios is that the design allows generation of two synchronized outputs. By essentially switching between two directions, a single laser is simultaneously operating as two different femtosecond lasers. The researchers predict that the power ratio from two outputs can be continuously tuned by replacing standard fiber couplers with a variable coupler.

"Our technique can be applied to imaging and sensing applications, allowing two different types of measurement simultaneously, which dramatically reduces the cost for the overall measurement system," says Maria Chernysheva, a Marie S.-Curie Fellow at Aston University. "In brief, the proposed yin-yang novel laser not only offers a cost-effective design, but more importantly shows an enhanced multipurpose laser capability with better tunability, improved light-beam quality, and easier power scaling."

REFERENCE

1. M. Chernysheva et al., Sci. Rep., 6, 24220 (Apr. 11, 2016).

Gail Overton | Senior Editor (2004-2020)

Gail has more than 30 years of engineering, marketing, product management, and editorial experience in the photonics and optical communications industry. Before joining the staff at Laser Focus World in 2004, she held many product management and product marketing roles in the fiber-optics industry, most notably at Hughes (El Segundo, CA), GTE Labs (Waltham, MA), Corning (Corning, NY), Photon Kinetics (Beaverton, OR), and Newport Corporation (Irvine, CA). During her marketing career, Gail published articles in WDM Solutions and Sensors magazine and traveled internationally to conduct product and sales training. Gail received her BS degree in physics, with an emphasis in optics, from San Diego State University in San Diego, CA in May 1986.