Diode arrays boost efficiency of solid-state lasers

The development of high-power diode arrays allows the use of highly efficient diode lasers for pumping solid-state lasers. Previously, solid-state lasers had been a standard method of delivering high-power laser pulses, but at the cost of low efficiency and cumbersome flashlamp pumps. The merging of diode arrays and solid-state technology to create diode-pumped solid-state lasers makes possible highly efficient, compact, high-power lasers for applications ranging from industrial processing to the measuring of gravitational waves.

Benefits of diode pumping

The advantage of diode pumping over flashlamp pumping does not lie in the intrinsic efficiency of the diode laser directly. In fact, the total efficiency of flashlamps in turning electricity into light is typically higher than that of diodes—about 70% for flashlamps compared with 50% for diodes. However, flashlamps produce a wide range of frequencies, while only a narrow range is actually used to pump the laser atoms into an inverted energy distribution. The result is overall efficiency of about 1%.

This very low efficiency means that energy sources must be large and cooling requirements great, making lasers bulky. And with 100 times as much energy liberated as used, thermal loads on the laser are correspondingly great.

In contrast, diode-pumped solid-state lasers (DPSSLs) can have high overall efficiency, because the diode lasers can pump energy directly into the excitation bands needed. Thus, overall efficiencies of DPSSLs are at least ten times higher than for flashlamp-pumped lasers. Overall efficiencies from "wall-plug" to output light from the solid-state laser can be around 10%. This translates into a tenfold reduction in the total amount of heating and concomitant reductions in the bulkiness of cooling systems. The inherent advantages of solid-state lasers are all retained: very high beam quality, nearly diffraction-limited beam divergence, high beam pointing and amplitude stability, high peak power, and repetitive pulsed-mode operation. In fact, much higher powers can be reached as thermal load per unit output drops.

Finally, system lifetime and reliability are much higher for DPSSLs than for flashlamp-pumped systems. Diode-pumped lasers have typical lifetimes of 10,000 hours continuous-wave (CW) or 109 shots, about 100 times longer than for flashlamps.

Diode-pumped solid-state-laser structure

There are two basic structures for DPSSLs—end-pumped and side-pumped. In end-pumped devices, a relatively small diode array is located at one end of the solid-state laser rod, and the pumping beams are aligned with the lasing axis. The diode array typically consists of a small number of stripe lasers in a single chip--for example, twenty 5-µm-wide lasers with a total CW output of 1 W.

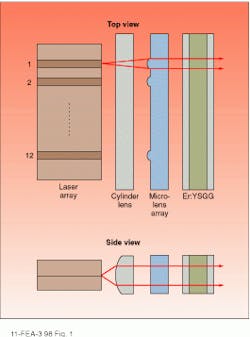

For higher powers, side pumping allows the use of larger diode-laser arrays along the side of a lasing bar or slab, with the pumping light aimed perpendicular to the lasing axis (see Fig. 1). Here, the basic building block is the bar laser, with subarrays of 20 stripes each grouped into bars with as many as 200 lasers in a CW device or 1000 lasers in pulsed devices. The bars are limited by their heat dissipation, with a typical 1-cm-long bar producing 20-W CW or 60-W pulsed power.

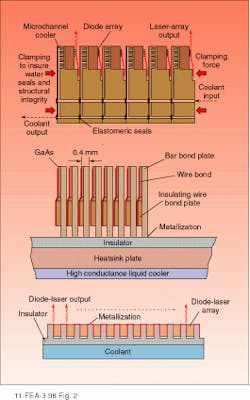

To achieve still higher power, bars are stacked into two-dimensional arrays. The duty cycle and average power output of such stacks is entirely dependent on their thermal design. In one common approach to cooling, termed microchannel or back-plane cooling, each diode bar has its own integral heat exchanger. Another approach is soldering each bar in the array to a common heat sink. Alternatively, the bars can be imbedded in grooves in a heat sink (see Fig. 2). Bar spacings range from 0.5 to 2.0 mm, allowing a power density of 300-1500 W/cm2, with higher power densities and closer spacing corresponding to lower duty cycles, ranging from 3% to 20%.Fighting thermal effects

One of the key gains of going to diode pumping is reducing thermal loads on the laser rods and the concomitant thermal distortion and fracture. But for high-power DPSSLs, thermal loading is still a big area of concern. This is particularly true for end-pumped lasers, where the energy is deposited in the central region of the rod. Even for side-pumped lasers, energy distortion can be quite uneven due to the necessary focusing of the pump radiation, and thermal distortion remains a problem.

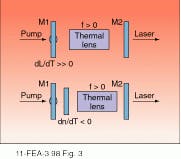

For example, with a focused pump spot a few hundred microns across, thermal distortion can produce a thermal lens with a focal length as short as 6 cm for pumping power of a few watts. Thermal lensing occurs because of the changes in refractive index caused by the heating of the lasing rod.

To compensate for such strong thermal lenses, convex input mirrors are used in the laser resonator cavity. However, the degree of thermal lensing varies as the pump power increases, so some alteration has to be made in the resonator to maintain good optical quality. Either the length of the resonator cavity can change, or the curvature of the compensating mirrors can change. This can be done by making the mirror from a deformable membrane or using a segmented mirror with segments controlled by piezoelectrically driven actuators.

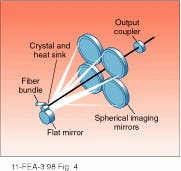

Recent research by R. Koch of Jenoptik (Jena, Germany) suggests using the pump-power source to automatically modify compensating elements. In one variant of this idea, light from the pump beam passes through a convex mirror made of material with a strong positive coefficient of thermal expansion. Alternatively, the beam can pass through a lens with a strong negative thermal-expansion coefficient (see Fig. 3). In either case, as the thermal lens within the laser rod increases in power, so automatically does the compensating lens or mirror. Because this is a linear phenomenon, once the two lenses are in balance, they will remain in balance as pump power varies.This design ensures that thermal lensing is minimized as the temperature gradient in the crystal is nearly in the same direction as the laser beam. Pump-power densities at the end of the fiber bundle can be as high as 5 kW/cm2.

DPSSL applications

The most widespread applications of DPSSLs are in industry, where compact and portable sources of high-quality, high-power laser beams are needed. The inherent advantages of solid-state lasers are very high beam quality, nearly diffraction-limited beam divergence, high beam-pointing and amplitude stability, high peak power, and repetitive pulsed-mode operation. Diode pumping adds to these advantages by providing low thermal loads, high efficiency, and compactness.

Diode-pumped designs allow lasers with high levels of power to be essentially hand-held devices. Lasers with outputs of several watts can be obtained from diode-array and laser-rod combinations that measure only a few centimeters on a side. With these capabilities, DPSSLs are increasingly becoming the lasers of choice for industrial processing and surgical applications.

In addition, the unique attributes of DPSSLs have made them the focus of more exotic research applications. As reported in an earlier Back to Basics article (see Laser Focus World, Aug. 1998, p. 157), researchers at Lawrence Livermore National Laboratory are now designing a new generation of giant laser for use in thermonuclear fusion experiments. Such huge diode-pumped lasers with megajoule outputs at overall efficiencies of more than 8% could, in theory, lead to practical fusion power generation.

At the low-power end, DPSSLs exhibit high intrinsic frequency stability, low amplitude noise, as well as high efficiency, making them ideal for the most sensitive measurement applications. Perhaps the most extreme measurement application of DPSSLs is measuring gravitational waves. These waves, hypothesized by Einstein`s theory of general relativity but never observed, are moving alterations in the curvature of space-time. By observing tiny frequency shifts in laser beams bounced down kilometer-long tunnels at right angles to each other, scientists hope to detect such waves as they distort the space they pass through.

Using a 100-W diode pumped CW Nd:YAG laser, researchers hope to achieve the ability to detect transient changes in length of one part in 1021, the ability to detect the change in length of a kilometer tunnel by a thousandth of the diameter of an atomic nucleus. The detection of such gravitational waves would both test Einstein`s theory and allow researchers to study extremely energetic phenomena in the universe, such as the catastrophic merging of stars.

FURTHER READING

I. Freitag et al., Appl. Phys. B 60, S255 (March 1995).

R. Koch, Opt. Commun.140, 158 (July 1997).

About the Author

Eric J. Lerner

Contributing Editor, Laser Focus World

Eric J. Lerner is a contributing editor for Laser Focus World.