Glenn Ogura, Jim Angell, and David Wall

Part I of this article, presented in the May issue of Laser Focus World, gave an overview of micromachining technology and of current market and technology drivers of laser micromachining. Part II explores laser micromachining applications by market, looking closely at those applications in which lasers have advantages over traditional nonlaser technologies.—Ed.

A paramount application for micromachining is the manufacture of integrated-circuit (IC) chips as IC chip sizes shrink and the complexity of their circuitry increases. Laser micromachining technology is contributing in two ways to bring about an increase of circuit complexity without sacrificing chip space. As pin counts of higher-end microprocessors and control chips exceed 208, ingenious technologies such as ball grid arrays, chip scale packaging, and flip-chip bonding allow ICs to be connected to printed wiring boards (PWBs) by drilling microvias in plastic carriers. Second, use of multichip modules allows complex ICs to be placed closer together, requiring high-density interconnects. Microvia technology is becoming increasingly popular in rigid PWBs, as witnessed by the emergence of several PWB laser-drilling-equipment manufacturers.

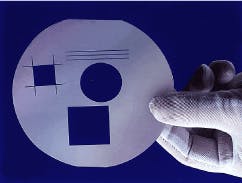

In the hard-disk-drive arena, flexible printed circuits (FPCs) are replacing thin wires as the electrical interconnects between the four-pin head and the drive circuitry (see Fig. 1). Lasers are being used to drill the interconnect pads and excise the FPCs themselves. In both these areas, there is an active merging of solid-state, CO2, and excimer technologies in which process throughput, quality, and feature size play key determining factors.

Ceramic machining and scribing of microwave devices is another common application in which CO2 lasers have played a prominent role. Ceramics are also used as substrates for multichip modules.

The use of excimer lasers in lithography exposure tools is truly one of the remarkable stories of the 1990s. After years of promise, these deep-UV tools are providing the pathways to 0.18-µm linewidths and beyond to produce DRAMs, utilizing both refractive and reflective (catadioptic) imaging systems.

Solid-state lasers are being used to repair reticules of lithography tools and for etching or depositing thin film on photo masks. Patterning of thin metal oxides is also used in high-end memory devices. In fast prototyping applications, ICs are repaired or diagnosed by exposing the underlying circuits with laser technology.

Dry cleaning of wafers using laser technology is making its way to the marketplace, competing with aqueous, carbon dioxide, vapor-zone, ultrasonic, UV-ozone, and plasma-based technologies. The laser beam irradiates the wafer surface with or without reactive agents to remove unwanted angstrom-deep contaminants. Reducing high entry-capital-equipment costs and improving performance are key market issues.

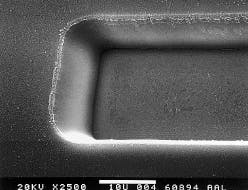

Both surface and bulk machining of silicon are used in the manufacture of microelectromechanical devices. All laser types are being used to directly machine silicon as an alternative to more-traditional lithographic technologies. Lasers are also being used to manufacture assemblies for IC diagnostic tools.

Passive resistor and capacitor trimming is an established application in the hybrid electronics markets, which require high precision and placement. Precise machining of quartz crystals (for high-frequency clock generation) is also a laser application.

Data storage devices

For many micromachining enthusiasts, the data storage market is synonymous with the Winchester disk drive market. As the core technology evolves from inductive to magneto-resistive to giant magneto-resistive to near-field to magneto-optic, a variety of laser micromachining applications have emerged to keep pace with this dynamic industry. Lasers are used in stripping tiny wires to connect the head to the drive circuitry. Today lasers are making tiny via interconnects for the replacement FPC market. Lasers have been investigated to sculpt air bearings to allow heads to travel at the optimum glide height, especially as storage demands increase.

The demand for high surface quality of high-density drives can be met with diode-pumped solid-state lasers, which offer superior pulse-to-pulse stability, high repetition rate, and solid-state reliability. This application has been extended to high-density floppy drives and other storage devices (see Fig. 2).The emergence of digital tape devices such as VCRs, DVCs, and DVDs presents an opportunity for using laser technology to produce the recording heads. As digital television becomes more prominent, this market will open up similar applications.

In medicine, laser microdrilling or slotting of nonintrusive devices such as F1-F4 catheters or medical stents for cardiovascular and neurological applications is a growing application. In the field of electrophysiology where tiny electric fields are used for various treatments or diagnosis, such as for the cardiovascular system, lasers to remove insulating material from electrodes or provide direct metal patterning. In the area of micro drilling gas and liquid orifices, lasers are used in the manufacture of tubes for intravenous drips, oral sprays, and gas delivery.

Microfluidics is currently a hot topic for DNA analysis, DNA sequencing, tagging DNA fragments, and other types of high-speed drug screening. Micromachining technology can be used in several ways, including forming micro channels, injection heads, and diagnostic orifices. Solid-state lasers are used to manufacture medical diagnostic equipment.

Cell phones and personal computers

As the bandwidth expands, micromachining technology is being used for fabrication of several kinds of optical circuits, from fiber Bragg gratings to wavelength-division multiplexers to "repeater-type" circuits (see Fig. 3). This trend can only continue as fiberoptic technology makes its way into the home as the communications link for digital television. The explosion of the cellular telephone market has brought about the emergence of micro via laser drilling technology to keep portable phones light and compact.Aside from the actual fabrication of integrated circuits or the packaging methodology within the computer itself, computer peripherals are also benefiting from laser micromachining technology. Display technology is rapidly changing from the traditional cathode ray tube (CRT) to various flat-panel-based technologies such as liquid-crystal and electroluminescent displays. This $20 billion market is using lasers for the crystallization of amorphous silicon to control the brightness of individual pixels. Direct film patterning of thin metals (such as indium tin oxide) is becoming more cost-effective than conventional multi-step processes.

Printing technology has escalated to new heights as both ink jet and laser jet technologies are invading the home, office, and industrial market place. Laser micromachining plays an important role in the manufacturing of print heads, a role that can be extended into other manufacturing assemblies as well.

Other markets also benefit from laser micromachining technology. In the aerospace market, lasers are used as precision paint strippers for aircraft or for turbine blade trimming. In the automobile industry, lasers can be used in microelectromechanical fabrication of accelerometers and tire pressure sensors, especially in rapid prototyping stages. Lasers are also used to machine combustion cylinders to make them more efficient by reducing the friction along the cylinder walls.

Lasers play a major role in the world`s pursuit of alternative energy sources such as uranium recovery or the manufacturing of diagnostic tools for the various laser fusion programs.

Future market drivers

The continued growth of laser micromachining in contract manufacturing, with the added benefit of more laser equipment sales, will partially depend upon the key technology and market drivers described in Part I of this article. However, as with most fast-track technologies, developers are looking for the elusive "killer application" that will spark continued industry growth. One asks: Where is the Word Processor or the 1-2-3 spreadsheet of the laser micromachining industry? Perhaps the answer already lies among present micromachining applications. But the answer will most likely come from the consumer market where high volume will drive both technology and market enthusiasts to find a cost-effective solution: data storage devices, cellular phones, and PCs are three prime candidates.

Future technology drivers

Novel laser sources as well as the use of existing laser sources for micromachining is one area of technology expansion. Ultrafast sources such as femtosecond and picosecond lasers may open up new applications. Their high peak power and short temporal pulse may allow precise machining with less HAZ (heat affected zone). Ion and copper-vapor lasers may also find micromachining applications. For example, the latter can be used to drill printed-circuit boards.

Certainly the greatest activity lies in the solid-state arena where diode-pumped technology is encroaching on lamp-based lasers. There will be further development of higher-power CW lasers and of nonlinear crystals working efficiently in the UV regime. There already exist Q-switched Nd:YAG lasers that emit in the deep UV. The smaller footprint, air cooling, high wall-plug efficiency, and energy stability are some of the reasons for the laser industry`s optimism. There is also activity with diode-pumped slab lasers.

Speed is the buzz word in many consumer-driven products. Therefore pulsed lasers will increase in both average power and repetition rate. On the optical beam delivery front, novel techniques such as diffractive optics, galvos, spinning mirrors, and holographic techniques allow laser light to be put in a specific location in an expedient manner.

For applications requiring clean rooms, such as the semiconductor or medical device markets, there is a trend toward making laser sources smaller. Examples include diode-pumped solid-state lasers, small ophthalmic excimer lasers or RF-excited CO2 lasers. Lasers are also becoming more environmentally friendly, with components such as solid halogen generators for excimer lasers.

New applications continue to expand the usefulness of laser micromachining and are proving it to be a viable competitor with other micromachining technologies. The future of lasers in manufacturing will be determined by how the industry reacts to the ever-changing markets and how it can adjust the technology to meet applications not realizable by traditional nonlaser techniques. A telling sign of success will be the healthy coexistence of laser manufacturers, laser systems companies, laser integrators, job shops, and contract manufacturers.

GLENN OGURA is vice president, marketing, JIM ANGELL is applications manager, and DAVID WALL is director of sales at Resonetics, 4 Bud Way, #21, Nashua, NH 03063; e-mail: [email protected].