LASER ISOTOPE SEPARATION: Laser uranium enrichment returns from the dead

Satisfied with tests it completed last year on the Silex process for laser enrichment of uranium, GE Energy (Atlanta, GA) wants to build a massive nuclear-fuel plant based on the process. It’s a surprising recovery for molecular laser isotope separation, a technology once largely given up for dead. But critics are raising questions about its potential for nuclear proliferation, and the plan must be approved by the Nuclear Regulatory Commission (NRC), which expects a mid-2012 decision.

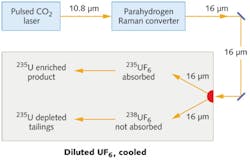

The Los Alamos National Laboratory first developed molecular enrichment in the 1970s, seeking a more energy-efficient process to produce nuclear-reactor fuel. It used a 16-µm laser source to selectively excite uranium hexafluoride (UF6) molecules containing fissionable U-235. But the Department of Energy eventually picked the competing atomic-vapor laser isotope separation (AVLIS) process, which selected vapor-phase U-235 atoms. Although uranium vapor posed problems, AVLIS won because it used more mature copper-pumped dye lasers, and it also could be adapted to purify plutonium for nuclear weapons. However, the United States Enrichment Corp. (Bethesda, MD) abandoned AVLIS in the 1990s.

Supported by US Enrichment from 1996 to 2002, Australian scientists Michael Goldsworth and Horst Struve developed Silex as a variation on molecular enrichment. Details are highly classified as well as proprietary, but it’s believed to rely on 16 µm excitation of UF6 molecules containing U-235, followed by a second excitation step that frees a fluorine atom from the excited molecules, producing solid UF5 that settles out from the gaseous UF6. They formed Silex Systems Ltd. (Lucas Heights, NSW, Australia) to commercialize the process, and later licensed it to GE Energy, which formed a partnership with Hitachi called Global Laser Enrichment.

A 2005 evaluation of the technology by John Lyman of the Los Alamos National Laboratory (Los Alamos, NM), made public two years later, warned that then-current Silex technology was inadequate for practical enrichment. The system used high-pressure para-hydrogen cells to shift the 10.8 µm line of a pulsed carbon dioxide laser to 16 µm, but overall efficiency was only about 0.25%. Worse, the repetition rate was only 50 Hz, which left 99% of the UF6 in the feed stream unprocessed.

U-235 enrichment to 3.6%

Those limitations appear to have been overcome. GE-Hitachi documents filed with the NRC disclose plans to build a massive reactor-fuel plant in a series of six stages, the first with 1 million separative work units (SWUs) of capacity, and each succeeding stage adding another 1 million SWUs to reach a final capacity of 6 million SWUs. At the final scale, the plant each year could produce more than 1000 tons of fuel for standard light-water reactors, containing 3.6% U-235. GE plans to clear 100 acres in Wilmington, NC for the facility. NRC documents do not identify projected cost, but the New York Times has estimated cost at $1 billion.

The documents give little clue of the nature of the crucial advance, although it likely has to do with the laser source. One possibility is higher repetition rates for the Raman-shifted pulsed CO2 source. Another is shifting to a different source, such as quantum-cascade lasers, which have been demonstrated emitting directly at 16 µm but only at relatively low powers.

Government-imposed security requirements, as well as proprietary interests, limit details available on the process. Silex says only that its process can increase U-235 concentration by a factor of 2 to 20, but the exact number is classified. In any case, that’s a higher factor than the 1.3 for centrifuge enrichment and 1.004 for gaseous diffusion. Such a high enrichment factor would reduce both capital equipment and operating costs, giving lasers an advantage over the older processes.

With little known about Silex technology, assessing its potential impact on nuclear proliferation is very difficult. “The most fundamental question is can this technology be effectively used to produce highly enriched uranium” that could be used in nuclear weapons, says James Acton of the Carnegie Endowment for International Peace (Washington, DC). So far, he doesn’t have enough information to know the answer. Another key question, if high enrichment is possible, is how well a small plant could be concealed from spy satellites; that, too, is unanswered. “This is not an attempt to stop the technology,” says Acton. “It’s an attempt to understand its implications before we commercialize it.”

Jeff Hecht | Contributing Editor

Jeff Hecht is a regular contributing editor to Laser Focus World and has been covering the laser industry for 35 years. A prolific book author, Jeff's published works include “Understanding Fiber Optics,” “Understanding Lasers,” “The Laser Guidebook,” and “Beam Weapons: The Next Arms Race.” He also has written books on the histories of lasers and fiber optics, including “City of Light: The Story of Fiber Optics,” and “Beam: The Race to Make the Laser.” Find out more at jeffhecht.com.