KMLabs commercially introduces direct diode pumped Ti:sapphire ultrafast laser

After years of development, KMLabs (Boulder, CO) has commercially introduced the first titanium sapphire (Ti:sapphire) ultrafast laser oscillator directly pumped with blue-emitting laser diodes. Conventionally, Ti:sapphire lasers have been pumped with 532 nm (green) emitting frequency-doubled neodymium:YAG (Nd:YAG) lasers, or, more recently, smaller frequency-doubled vanadate lasers. Using direct-diode pumping instead greatly reduces the cost of the Ti:sapphire laser oscillator system. In fact, KMLabs has found that it is now possible to pump a Ti:sapphire laser with a single inexpensive 4 W blue laser diode.

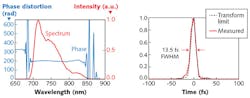

The new diode-pumped Ti:sapphire laser, which KMLabs calls the Stryde Blue, is, according to the company, a "fully engineered and integrated commercial source based on a single rugged optomechanical platform, and eliminates the need for costly frequency-doubled vanadate pump lasers." KMLabs says the Stryde Blue is pumped by a single integrated laser diode, produces sub-15-fs pulses with a beam quality (M2) of typically better than 1.2; a 150 mW average power and 2 nJ pulse energy at a 78 MHz repetition rate; demonstrates a long-term stability of better than 0.5% root mean squared (RMS) over a time span of >500 hours; has computer-controlled tuning of its center wavelength and spectral bandwidth; and is well suited for standalone experiments, seeding of ultrafast laser amplifiers, or teaching labs. Applications include amplifier seeding, materials research, femtochemistry, spectroscopy, terahertz generation, ultrafast imaging, two-photon polymerization, and pump-probe experiments. Reference: https://goo.gl/vYXdV3.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.