Novel Lasers: Heat sink sandwich extends wavelength for semiconductor membrane laser

HERMANN KAHLE, CHERRY MAY MATEO, ROMAN BEK, MICHAEL JETTER, and UWE BRAUCH

The output power of semiconductor disk lasers is ultimately limited by the ability of the heat sink to remove waste heat. By containing an active laser medium of quantum wells (QWs) or quantum dots (QDs) in a membrane sandwiched between diamond or silicon-carbide heat sink materials, laser-media cooling is maximized to enable 0.6 W of diffraction-limited output at a wavelength of 657 nm when pumped at 532 nm.

Beyond this initial demonstration, our team anticipates further improvements if the QWs are directly pumped to reduce the heat load. The symmetric transmissive sandwich configuration of this semiconductor membrane laser minimizes thermal effects on the laser resonator and the beam quality, while the absence of the distributed Bragg reflector (DBR) mirror extends the possible range of material combinations and wavelengths.

Designing the membrane

The disk-laser concept produces solid-state lasers at kilowatt output power levels with good-to-excellent beam quality at optical efficiencies above 50%, despite the comparatively high transparency density of the usually preferred ytterbium yttrium aluminum garnet (Yb:YAG) disk.1 This can be attributed mainly to the optimized cooling geometry with the thin disk via the rear-side high-reflectivity (HR) mirror that is in direct contact with the heat sink, and with a heat flow predominately collinear with the resonator axis.

Actually, semiconductors should be an even-better choice for a disk-shaped gain material with the QW or QD layers just a few nanometers thick, with the semiconductor epitaxy being the preferred production method both for the active region, containing the QW or QD layers, and the highly reflective DBR mirror.

Another advantage of semiconductor disk lasers over Yb:YAG designs is that the thicker spacer layers in between the QWs can conveniently be used as absorbers for the pump radiation that makes the multipass optics of solid-state disk lasers obsolete.2 The disk concept in general allows very efficient second-harmonic generation (SHG) within the cavity because of the low optimum output coupling and strongly enhanced circulating power. This is even more interesting in combination with the large range of fundamental wavelengths that are accessible with semiconductors of different material combinations.3

Unfortunately, strongly depending on the material system, semiconductor disk lasers are more or less limited with respect to output power. Reasons include a somewhat higher transparency threshold, a higher heat load because of spacer pumping with photons of significantly higher energy than the lasing photons, a stronger increase of losses for elevated temperatures, and a DBR with a large number of alternating layers because of the low contrast of the index-of-refraction, thus constituting a high heat barrier.

Generally, one relies on small pump spots (beam diameter <1 mm) in combination with copper or diamond heat spreaders that result in a more efficient, predominately three-dimensional heat flow. This reduces the temperature of the active layer for a given heat-load density, but limits the output power because of the small pump spot and laser mode area.In cases where the DBR is the main problem, intracavity heat sinks in direct contact with the active region are used, allowing the heat flow to bypass the DBR. In this way, the output power of red-emitting gallium indium phosphide (GaInP) disk lasers was raised into the watt range.4

Prerequisites include a good optical and thermal contact between heat sink and disk (through liquid-capillary or chemical bonding, or simply by mechanical pressure), and low insertion losses because of absorption, scattering, or birefringence of the heat sink (usually made of monocrystalline silicon carbide or diamond). Low resonator losses are especially important if one wants to keep the transparency and laser threshold power density low by using the smallest possible number of QWs.

The next logical step has been to abandon the DBR and to sandwich the active-region membrane in between two heat sinks. By doing this, each heat sink handles only half of the original power, and the maximum distance for the heat flow within the disk is also reduced by half. The maximum temperature rise within the active region should therefore be reduced by a factor of two to four, depending on whether the temperature gradient is mainly generated outside or inside the disk.

For a given maximum operating temperature, the heat-sink sandwich allows the design to progress towards larger pump spot sizes with a higher contribution of less-efficient one-dimensional cooling. If the cooling capability per unit area is relaxed to one half, the pump spot diameter can be 2–3X larger, translating into a 4–5X larger output power.5 The positive side effect is that there is no longer a need to grow a lattice-matched DBR mirror, making it possible to use a wider range of material compositions for the active region and, consequently, increasing the range of available laser wavelengths.

Fabricating the membrane

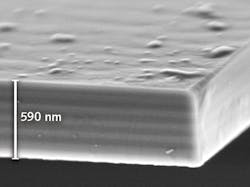

To physically fabricate the heat sink/membrane/heat sink sandwich, a process was developed that required the ability to detach the active region (typically several hundred nanometers thick) from the substrate and mount it in between the heat sinks.

To accomplish this, after epitaxial growth of the active region and the necessary sacrificial layer, the wafer is cleaved into pieces, and the epi-side glued to a silicon carrier. An aluminum arsenide (AlAs) sacrificial layer between the substrate and active layers allows complete removal of the substrate by wet chemical etching.

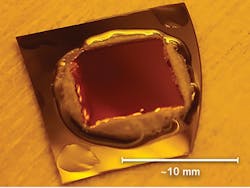

In a second etching process, this sacrificial layer is then removed, leaving only the active region on the silicon carrier wafer (see Fig. 1). After dissolving the glue, the then-free-floating membrane can be "picked up" by one of the heat sink substrates.

The heat sink with the membrane on top is then transferred to the sample holder, where the second substrate is put on top of the first one using a collar nut to apply some pressure (see Fig. 2). While tightening the nut, the reflections and interference effects at the heat sink/liquid/membrane interfaces disappear, indicating optical contact.The design of the active region is quite similar to that of the standard semiconductor disk laser. Because of the (comparably small) difference of the refractive index between membrane and heat sinks, there is still some standing-wave contribution to the electrical field that modulates the intensity within the membrane.

For a resonant design with maximum gain, the membrane thickness must be carefully considered, and the QWs or QDs should be packed periodically at the antinodes of the intensity distribution within the disk to maximize resonant periodic gain (RPG).

The simplest external resonator is an approximately concentric cavity with the sandwich at the beam waist oriented normally to the resonator axis, with the outer sides of the heat spreaders having antireflection (AR) coatings. There is obviously no restriction imposed by the DBR on the pump wavelength for barrier pumping—that is, the part of the pump radiation that is not absorbed in the active region is simply transmitted and, if necessary, can be easily reimaged on the membrane by an external mirror for a second pass.

Assembling the membrane laser

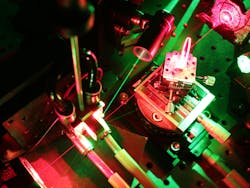

Using a membrane with five groups of four GaInP QWs in an RPG arrangement squeezed between two 0.5-mm-thick monocrystalline diamond windows, operation of a membrane external-cavity surface-emitting laser (MECSEL) was demonstrated for the first time with 595 mW of output power at a wavelength of 657 nm (see Figs. 3 and 4). Pumped with 3.7 W of incident and 3.0 W of absorbed power at a wavelength of 532 nm, MECSEL performance was limited only by thermally induced power collapse.6Besides maximizing the heat extraction, minimizing the thermal load is another option to improve the performance of disk lasers. Pumping the QWs directly with a wavelength 5–10% shorter than the laser wavelength allows reduction in the heat load by a factor of two to four. Then, multiple passes of the pump beam are necessary to ensure high absorption efficiency.

Since internal resonances are fairly weak in this minimized thermal load configuration, external multipass optics are needed for the MECSEL when adapted to a transmissive disk form. This can simply be a combination of two standard (reflective) multipass optics on either side of the membrane.

Another option is to use transmissive optical elements to shift the beam in between the passes, combined with a parabolic mirror on either side. Since there is no need for a DBR mirror, new wavelength ranges may become accessible using these membrane lasers. In particular, an aluminum gallium indium nitride (AlGaInN) system reaches the blue/near-ultraviolet spectral region, where the DBR is difficult to realize because of the very different lattice constants of GaN and AlN, as well as the low index contrast of the AlInN with respect to the AlGaInN material system. The AlGaInP-based lasers are currently limited on the orange spectral side by the absorption of the DBR and on the near-infrared side by the mismatch of the lattice constants needed for the active area and the DBR.

The processes needed to prepare the MECSEL devices, such as large-scale bonding of whole wafers to transparent substrates followed by removal of the original substrate, are common in industry and generally available for most semiconductor material systems. The flexibility in designing its active region, combined with the possibility of stacking several active-region membranes, creates a high level of adaptability for the MECSEL. No doubt, existing gaps in the available wavelengths of high-quality semiconductor lasers will be further narrowed in coming years as the MECSEL continues to evolve.

REFERENCES

1. S.-S. Schad et al., "Recent development of disk lasers at TRUMPF," Proc. SPIE, 9726, 972615 (Mar. 16, 2016); doi:10.1117/12.2212789.

2. M. Kuznetsov et al., IEEE Photon. Technol. Lett., 9, 8, 1063–1065 (1997).

3. O. G. Okhotnikov (ed.), Semiconductor Disk Lasers, Wiley-VCH Verlag GmbH & Co. KGaA, Weinheim, Germany (2010); doi:10.1002/9783527630394.

4. T. Schwarzbäck et al., Appl. Phys. B, 102, 4, 789–794 (2011).

5. U. Brauch et al., "Schemes for efficient quantum-well pumping of AlGaInP disk lasers," Proc. SPIE, 10087, 1008703 (Feb. 22, 2017); doi:10.1117/12.2250901.

6. H. Kahle et al., Optica, 3, 12, 1506–1506 (2016).

Cherry May Mateo and Roman Bek are PhD students, while Hermann Kahle, Michael Jetter, and Uwe Brauch are researchers, all with the Stuttgart Research Center of Photonic Engineering (SCoPE) at the University of Stuttgart, Stuttgart, Germany; e-mail: [email protected]; www.scope.uni-stuttgart.de.