Mid-IR Lasers: Ultranarrow-linewidth mid-IR laser family could span 2.5 to 9.5 μm

A group at the University of New Mexico (Albuquerque, NM) has developed—in theory, at least—a family of narrow-linewidth mid-infrared (mid-IR) lasers of novel design: they are distributed-feedback Raman fiber lasers (DFB RFLs) based on π-phase-shifted fiber Bragg gratings (PPS-FBGs) written in a glass fiber called a low-phonon-energy fiber. The family of fiber lasers spans the spectral region of 2.5 to 9.5 μm with no gaps.1

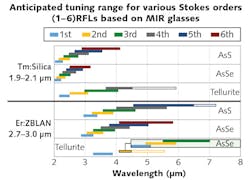

Pumped with either a thulium-doped silica (Tm:silica) fiber laser emitting at 1.9 to 2.1 μm or an erbium-doped fluoride (Er:ZBLAN) fiber laser emitting at 2.7 to 3.0 μm, the PPS-DFB-RFLs are made of arsenic sulfide (AsS), arsenic selenide (As2Se3), or tellurite (TeO2); the choice of material and pump laser determines the laser's tuning range (see figure).

Proof of concept

The purpose of the theoretical study was threefold, the authors say. First, they wanted to demonstrate feasibility of the new Raman laser type; second, they aimed to specify the optimum design for single-mode or single-frequency lasers of this type; and third, they wished to sketch out approaches for future experimental efforts.

The lasers are potentially viable because stimulated Raman scattering with high Raman gains can be achieved in low-loss optical fibers at most wavelengths in the transparency windows of the fibers by using moderate pump powers at pump wavelengths corresponding to a broad range of Stokes shifts. In addition, cascading multi-Stokes processes open up new wavelength possibilities.

The choice of glass for a Raman fiber laser for a specific wavelength range is based on the availability of near-single-mode fibers in that wavelength region, the magnitudes of the peak Raman gain coefficients, the needed values and ranges of the Raman shifts, and whether or not PPS-FBGs with high-enough efficiencies can be created in the fibers.

In one example of their calculations, a laser output wavelength of 3.596 μm was chosen, which is the wavelength used for sensing of formaldehyde via absorption spectroscopy. The researchers modeled two lasers—one based on TeO2 (core refractive index of 2.7; nonlinear index of 1.1 × 10-17 m2/W) and the other based on As2Se3 glass (core index of 2.1; nonlinear index of 5.0 × 10-19 m2/W). While commercial fibers of these types have mode areas of around 100 μm2, newly developed photonic-crystal fibers have much smaller mode areas of around 10 μm2—the researchers used these for their models.

The calculations showed threshold pump powers below 80 mW at 3.3 μm and 500 mW at 2.8 μm for the As2Se3 and TeO2 lasers, respectively, both for laser lengths of 10 to 12 cm.

The model shows that ultranarrow linewidths of <1 MHz are achievable. The researchers believe that optimizations could lead to the ability to pump these fiber lasers with more than 50 W of power, resulting in an ultranarrow-linewidth output power in the watt-level range for some wavelength ranges. The ultimate power is limited by factors such as thermal or other changes in the refractive index of the fiber, causing phase anomalies in the PPS-FBGs, and possibly by material-damage thresholds.

The lasers can be tuned by mechanically stretching the FBGs, for example, by using piezoelectric actuators, achieving continuous tunabilities on the order of 1 nm.

REFERENCE

1. B. Behzadi et al., arXiv:1705.02535v1 [physics.optics] (May 6, 2017).

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.