Photonics Products: Tunable Lasers: Commercial quantum-cascade laser technology matures

Since its invention, the quantum-cascade laser (QCL) has remained at the forefront of mid-infrared (mid-IR) laser technology. This holds true not only for the results of academic research, but also for the leading-edge features regularly being introduced in commercial QCL products.

For this article, we avoided doing a broad survey of QCL products and instead asked executives and other leaders at well-known QCL companies specifically what they thought some of the most interesting technical innovations recently introduced by their companies were. Here is what they said.

Kumar Patel, president and CEO, Pranalytica (Santa Monica, CA)

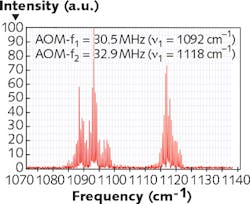

Recently, we have made an improvement to our ultrarapid-scanning tunable QCL system (VeloXscan) that is very important.1,2 It involves simultaneous two-wavelength operation of the system, where we can tune two independent wavelengths independently in the VeloXscan. Each one of the wavelengths can be switched in <550 ns to any wavelength in the lasing spectrum and can be controlled independently. This is done by providing two independently variable RF frequencies to the acousto-optic modulator (AOM) that determine the operational wavelengths of the tunable QCL.

Since the AOM modulator operation is linear, the two acousto-optic RF drive frequencies set up two independent phase gratings in the AOM and give rise to the QCL operation at two independent wavelengths.

Initially, we have used the two-wavelength operation to extract the actual lifetimes of the lasing levels of the QCL. This is the first time where the lasing level lifetimes have been measured in a real high-power QCL. This information is very important in designing and evaluating the new algorithms for high-power QCL structures.

Until now, designers have relied on calculations and the performance of the final device, which depends on many parameters, in addition to the design. These parameters include the reliability of the epi-growth and many subsequent operations that lead to a complete device. The lasing-level lifetimes, however, accurately reflect the structure design and will provide the needed crucial data for future improvements in QCL manufacturing.

The simultaneous two-wavelength operation (see Fig. 1), with independent control of each wavelength and its switchability in <1 μs, opens up an entirely new field of research involving pump-probe studies of combustion and explosion dynamics.

Kevin Lascola, product-line manager, mid-IR lasers, Thorlabs Quantum Electronics (Jessup, MD)

Thorlabs has introduced the Turnkey MIR Laser (see Fig. 2) for use as a mid-IR light source for laboratory applications in spectroscopy, metrology, illumination, and blackbody replacement. Previously, users working with mid-IR lasers have been forced to integrate external drive electronics and cooler controls as well as custom heat-sinking and collimation solutions before beginning work on their primary application or research.The Turnkey MIR Laser provides a collimated continuous-wave (CW) output in the mid-IR, and includes all necessary laser and thermoelectric-cooler drive systems. This includes internal and external modulation capabilities, along with a tuning input that can be used to lock the laser emission to a spectral reference.

The laser head contains an EEPROM that stores the wavelength and L-I-V (light-current-voltage) characteristics of the mounted laser, allowing the touchscreen controller to automatically adjust itself for calibrated plug-and-play operation. In addition, a USB 2.0 mini B connector allows remote operation using software written by the user in C, C++, C#, LabVIEW, LabWindows/CVI, or Visual Studio.

Thorlabs plans to continue to expand mid-IR packaging options through the addition of traditional laser-diode TO-style packages, improving both the accessibility and affordability of lasers in this important wavelength region.

Leigh Bromley, director, scientific products, Daylight Solutions (San Diego, CA)

The strong absorption of mid-IR laser light by molecules with characteristic spectral fingerprints is driving a wide range of molecular-sensing applications. These applications span pure research; environmental sensing; defense and security; life sciences; and process control.

The flexibility of QCLs-rugged, compact, and capable of pulsed, CW, narrow-linewidth, low-noise, or high-power operation-is making them the mid-IR laser source of choice in many applications. In general, molecular-spectroscopy applications (particularly in the commercial realm) benefit from rapid, high signal-to-noise ratio (SNR) data acquisition. This demands mid-IR lasers with highly repeatable, high-speed wavelength tuning and high-quality light output.

This need has driven the development of a new generation of QCL-based mid-IR lasers that provide a significant boost in tuning speed, but without sacrificing output fidelity. One example of this new generation of lasers is the Hedgehog laser from Daylight Solutions. Using a new high-speed tuning mechanism, this new laser platform delivers tuning speeds up to thousands of wavenumbers per second. By combining this new mechanism with field-proven laser cavity design elements, however, Hedgehog maintains the high power stability, near-diffraction-limited beam, and CW or pulsed output of Daylight's prior generation of lasers.

In addition to high scan speeds, the higher precision of the new tuning mechanism enables wavelength repeatability to ≤0.1 cm-1. Coupled with new QCL drive circuitry that enables CW relative intensity noise (RIN) as low as -140 dBc/Hz, Hedgehog gives users new performance capabilities with which to generate high-SNR molecular absorption spectra at high speed. As an embedded laser engine, this new laser design has already brought performance enhancements to molecular-sensing instrumentation, such as Daylight Solutions' new ChemDetect IR laser-based spectrometer (see Fig. 3).Petros Kotidis, CEO, Block Engineering (Marlborough, MA)

Block Engineering's LaserSense product line is the next-generation hydrocarbon analyzer for mud logging,3 BTU, Wobbe Index,4 and pipeline-mixing applications in the oil and gas industry (see Fig. 4). Using QCL technology and complex analysis algorithms, Block Engineering's LaserSense product can be adapted to offer real-time inline-analyzer solutions to complex application-specific demands for gas and liquid analysis.Current product developments include LaserSense models that identify and quantify up to eight gases simultaneously: C1-C6 (including isomers)5 in <10-second measurements. The advantage of the QCL technology allows for continuous inline monitoring without routine calibration or need for operator intervention.

LaserSense-ML is currently revolutionizing the mud-logging industry by giving geologists a user-friendly, fast analyzer that has become an essential tool in mapping the formations of current and future well sites. LaserSense-CV gives in-time BTU and Wobbe Index values that allows industrial users to closely monitor flare stack feedstock and composition of incoming fuel stocks. The use of a widely tunable QCL source has allowed application development to reach beyond gas analysis and into liquid blending as a quality control for pipeline-monitoring applications for consumers and producers in liquid natural gas (LNG) pipelines.

Keep watching

These four QCL innovations—three of them concentrating on the laser technology itself and the fourth on a crucial application—are but a few of the advances in QCLs that have happened and will happen in the commercial photonics arena. Be sure to keep an eye on this area, as the technical development talent involved as well as the flexibility of the QCL architecture itself allows for lots of room to grow.

REFERENCES

1. A. Lyakh et al., Appl. Phys. Lett., 106, 141101 (2015); http://dx.doi.org/10.1063/1.4917241.

2. C. K. N. Patel et al., Appl. Phys. Lett., 110, 031104 (2017); http://dx.doi.org/10.1063/1.4974214.

3. See https://goo.gl/4bWe0g.

4. See https://goo.gl/Fx05xL.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.