Yb:LuAG laser ceramic has efficient heat removal at high dopant concentrations

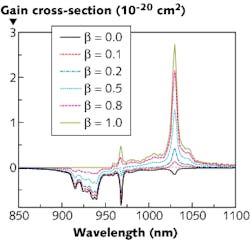

In the interest of developing a high-power ytterbium (Yb)-doped laser-gain medium that maintains a high thermal conductivity even when the Yb doping concentration is raised higher than 5%, a group at Nanyang Technological University (Singapore) has fabricated laser ceramics of Yb-doped lutetium yttrium aluminum garnet (Yb:LuAG) using a solid-state reactive sintering method, producing an almost pore-free microstructure for Yb doping levels of 5%, 10%, 15%, and 20% and a grain size of about 10 μm. The gain cross-section was measured under different population inversion ratios (β) over an 850 to 1100 nm spectral region (see figure).

The researchers used a 5%-doped sample 3 × 3 × 3 mm in size to create a laser that produced a continuous-wave output of 7.2 W at 1030 nm with a 65% slope efficiency. The sample was antireflection-coated and pumped at a 980 nm wavelength by a fiber-delivered laser diode. The researchers plan in the future to improve the cavity design, extract heat more efficiently, and further boost the doping concentration in combination with a shorter sample length. They note that the Yb:LuAG ceramic is a good candidate for use in high-power thin-disk lasers due to its high thermal conductivity and large emission cross-section of 2.7 × 10-20 cm2 at the 1030 nm emission peak. Contact Jian Zhang at [email protected].

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.