HIGH-POWER LASER DIODES: Wavelength stabilization improves laser diode efficiency and brightness

KENDRA GALLUP, WENTAO HU, ROBERT LAMMERT, and JEFFREY UNGAR

In his keynote address to the 1991 Diode Laser Technology Program conference in Washington, DC, the nuclear physicist Edward Teller famously asserted, “No one should use a laser unless it’s a diode laser.” Those of us who hail from the laser diode manufacturing industry will wholeheartedly endorse that statement, but even less biased observers will admit that there is considerable truth to what he said: Compared to other near-infrared (NIR) lasers, diodes are by a wide margin unsurpassed as efficient, low cost, compact, and rugged sources of radiation. Technological advances over the last two decades have more than substantiated Teller’s statement.

Because of these attractive features, diodes have carved out dominant positions in many laser applications. The market for laser diodes exceeds all other lasers combined, and it is a fair statement to say that the largest laser applications such as fiber-optic telecommunications and optical data storage—each of which is a multibillion-dollar per year market—would not exist at all without the laser diode.

In the interest of fairness, however, it must be admitted that laser diodes cannot do everything, and in two respects their performance lags behind other laser sources. The first deficiency is beam quality at high power. Above 1 or 2 W, commercial laser diodes do not provide diffraction-limited beams. And second, high-power diodes cannot match the brightness generated by their fiber, solid-state, and carbon-dioxide (CO2) laser brethren. But diode brightness is improving rapidly, and a time in the not very distant future can be foreseen where direct diodes will be used even for demanding applications such as keyhole welding. For the time being, however, the lower brightness of diodes shuts them out of most materials processing applications, and they are confined to uses such as plastic welding and heat treatment.

Spectral properties of laser diodes

For applications such as pumping of solid-state or fiber lasers, diode beam quality is adequate. A more serious issue is the output spectra, which for diodes are broader and less stable than other lasers.

The difference in spectra of diodes compared to other lasers has its origin in fundamental physics, which is best illustrated by comparing diodes to a typical solid-state laser. The active crystal of an Nd:YAG laser is lightly doped, with 99% of the crystal taken up by the passive YAG host, and only a small fraction by the active Nd ion, Nd+3. The Nd ions are on average spaced many atomic diameters from one another, and there is negligible overlap between their electron clouds. Broadening mechanisms such as host-crystal field Stark splitting do broaden the spectrum of each ion, but by and large the overall gain spectrum—and the laser output as well—reflects the narrow gain profile of the individual ion.

Laser diodes are fundamentally different. Gain is not generated by widely spaced atoms that are guests in a host crystal, but by the crystal as a whole. The semiconductor atoms the crystal comprises are nearest neighbors whose electronic states are so strongly overlapped that they lose their individual identity completely. Because of the Pauli principle, the individual energy levels broaden into energy bands.

Diodes, therefore, have very broad gain spectra, with spectral widths that are defined by Boltzmann-statistical thermal energy scales (typically 20 nm or so in the NIR) that are many orders-of-magnitude wider than solid-state lasers, and the gain spectrum changes with temperature due to crystal lattice-electronic state interactions.

As a result, laser diodes simultaneously oscillate in a large number of modes spread out over a wide range of frequencies. Multimode diode spectra are typically 1–3 nm wide and vary with temperature at a rate of 0.35 nm/°C for diodes emitting from 800 to 1000 nm. These numbers increase to 15–20 nm widths and >0.5 nm/°C temperature variations at 1400 nm and beyond. Moreover, peak wavelengths are poorly defined, and center wavelength manufacturing tolerances range from ±3 nm at shorter wavelengths to as much as ±10 nm at longer wavelengths.

For example, for Nd:YAG pumped lasers at 808 nm or fiber lasers pumped at 915 nm, the absorption lines are wide enough to make the broad emission spectrum of diodes a relatively minor issue. However, as demands on performance grow, attention is increasingly focusing on newer pump bands such as 880 nm in Nd for higher efficiency and beam quality, 976 nm for low-phase-noise ytterbium (Yb) fiber amplifiers, and 1532 nm for eye-safe erbium (Er) lasers. These lasers require accurately defined, well controlled, narrow linewidth pump sources that exceed the capabilities of standard diodes and arrays.

Controlling spectra with internal gratings

Narrowband optical feedback from an external diffraction grating can narrow and stabilize the spectrum of laser diodes. This technique has long been used to narrow the linewidth of single-emitter diodes, and with the advent of volume Bragg gratings (VBGs), stabilized arrays and fiber-coupled modules have become commercially available.

For VBG-stabilized diodes, expense is a consideration because of grating cost and the labor to individually actively align each bar to its grating. Locking efficiency and spectrum are sensitive to the optical alignment between diode and grating, and micron-level “smile” across each bar contributes to variations in locking efficiency and center wavelength. Accurate alignment between bar, collimating lens, and grating must be stably maintained over the lifetime of the pump system to prevent wavelength drifts. Most important, VBG stabilized systems cannot be broadly temperature tuned; tuning rates are only 10 pm/°C, which makes temperature trimming the pump source onto the absorption peak difficult.

An alternative is to use internal diffraction gratings that are monolithically fabricated at wafer level into the structure of the laser diode. This is similar to low-power distributed feedback (DFB) lasers that are used at 1550 nm for long-haul fiber-optic communications. Internal gratings offer many advantages, including simplicity, low cost of manufacture, long-term stability, and uniformity. Temperature tuning rates range from 80 to 150 pm/°C (depending on wavelength), providing enough tuning range to match absorption peaks, but still small enough so that precise temperature control is not required.

Brightlock laser diode sources

Until recently, internal-grating-based diodes were unavailable at high powers. Adapting monolithic grating techniques to high-power lasers required the QPC Lasers division of Laser Operations LLC to overcome challenges ranging from material epitaxy to multimode competition effects. But over the last few years, we have commercialized chip-based, internal-grating-stabilized laser diodes at a wide range of wavelengths, powers, and brightness levels under the trade name Brightlock.

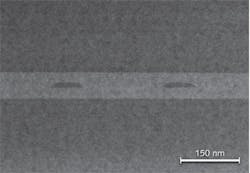

For a Brightlock 976 nm laser, for example, a monolithic diffraction grating layer is located within a few hundred nanometers of the quantum-well diode active layer and acts to periodically modulate the effective refractive index and generate selective feedback for the laser (see Fig. 1).

This second-order diffraction grating is fabricated in two steps: A corrugated pattern is first holographically formed on the surface of a multi-quantum-well epitaxial wafer by two-beam interference of an ultraviolet laser, after which a second epitaxial step is performed to embed the grating inside the semiconductor.

Brightlock pump modules were first developed at wavelengths from 792–980 nm in both free-space and fiber-coupled packages. Fiber-coupled packages can provide 30 W of stabilized 808 nm power with 0.3 nm linewidth into a 400 μm fiber. Other wavelengths followed. Pumping of Nd-based laser materials at 880 nm offers reduced thermal loading and beam distortion (see Fig. 2).Brightlock technology has been extended to longer wavelengths as well as higher powers and brightness. One case is providing narrowband pump power at 1532 nm for pumping Er-doped glass for eye-safe lasers. This system is challenging for two reasons: Typical 1532 nm unstabilized diodes have linewidths exceeding 15 nm, but the pump linewidth must be less than 3 nm for efficient absorption; second, long-wavelength diodes have spatial brightness that is inferior to 808 and 976 nm lasers, but because Er is a quasi-three-level system, pump spatial brightness must be very high for full inversion.

Within the last year, new developments in adapting Brightlock technology to high-spatial-brightness diode architectures have enabled diode sources with both narrow linewidth and spatial brightness. The 2-nm-wide output spectrum of a recent fiber-coupled laser yields 26 W at numerical aperture (NA) 0.15 from a 105-μm-core fiber (see Fig. 3). This corresponds to brightness exceeding 4 MW/cm2 sr—a figure that is higher than commercially available modules in the 808 nm band with no stabilization.Brightlock power at 1532 nm has also been scaled to very high total outputs, with pump systems providing as much as 10 kW at an overall linewidth of 2 nm. At longer wavelengths, narrowband pumping at 1908 nm is important for trivalent holmium (Ho) pumping to create 2100 nm beams used in various sensing and medical applications. The 2100 nm wavelength also serves as a jumping-off point for parametric conversion into the mid-IR.

The required 1908 nm pump beams were generated by a two-step process of diode-pumping thulium fiber such as Tm:YLF or by direct pumping of co-doped Tm:Ho crystals. With recent advances in Brightlock technology, direct diode pumping at 1908 nm is now practical (see Fig. 4).Internal-grating-stabilized pump diodes are still relatively unfamiliar, but they are expected to impact solid-state laser designs within the next few years.

Kendra Gallup is director of sales, North America; Wentao Hu is vice president of engineering; Robert Lammert is vice president of R&D; and Jeffrey Ungar is CTO at the QPC Lasers division of Laser Operations LLC, Sylmar, CA; e-mail: [email protected]; www.qpclasers.com.