The gain material in a solid-state laser is often rod-shaped—a geometry that is easy to work with and allows the straightforward extraction of a high-quality beam. This was the shape of the first operating laser, a flashlamp-pumped ruby laser demonstrated in 1960 by Theodore Maiman at Hughes Research. But for high-power lasers, the low surface-to-volume ratio of a typical rod can result in heat buildup within the rod that produces thermal-lensing effects and poor beam quality.

The surface-to-volume ratio of a cylindrical rod can be boosted by making the rod long and thin, or shortening it so much that it becomes a disk. The first approach has produced the fiber laser, high-power single-fiber versions of which have reached 1.3 kW output (see Laser Focus World, August 2004, p. 36). Multiple fiber lasers can be coupled into one fiber that emits a good-quality high-power beam (see "Fiber and disk lasers vie for attention in automotive industry," p. 7).

The second approach has been taken by Trumpf (Plymouth, MI), a maker of multikilowatt industrial lasers, which already produce a 1-kW continuous-wave diode-pumped disk laser containing two disks in its resonator; the laser has a beam quality of 6-mm mrad and an output that can be coupled into a 150-µm-diameter optical fiber.

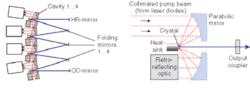

Now, Trumpf has bested its own 1-kW achievement by a factor of four. The company's newest disk laser—which contains four diode-pumped disks and is to be introduced at the International Manufacturing Technology Show 2004 (Chicago, IL; Sept. 8–15)—has a 4-kW output and a beam quality of 7 mm-mrad; its output can be coupled into a 200-µm-diameter fiber. Four 1030-nm-emitting ytterbium:YAG disks, each individually pumped, are contained within a resonator containing folding mirrors that create a zigzag path (see figure).

A 4-kW diode-pumped disk laser contains four ytterbium:YAG disks within its folded resonator (above left). Each disk module has parabolic reflecting optics to focus the pump light and a retroreflector to allow unabsorbed pump light to pass through the disk again (above right). Four mounted modules are lighted from within by green light to highlight their interior (left).

In addition to its short thermal path, the disk geometry allows cooling from the disk's back surface, which produces a thermally induced refractive-index distribution that is axial; a purely axial-index variation does not induce thermal-lensing effects. In contrast, the parabolic lateral-index variation that results from pumping a conventional high-power laser rod produces thermal lensing of a strength that is proportional to the pump power.

The 4-kW disk laser has a higher beam quality than conventional solid-state industrial lasers of similar output power. As a result, lenses with longer focal lengths can be used to achieve the same final spot size as conventional lasers combined with shorter-focal-length lenses. The result is a longer working distance and a larger depth of focus. For welding systems with fixed optics, this is beneficial for hard-to-access welding joints, providing increased spatter protection and tooling clearance, according to Tim Morris, technical sales manager at Trumpf. For systems with scanning optics, a longer focal length results in larger useful scanner x and y working ranges, Morris notes.