Recent improvements in short-pulse-width, short-wavelength UV diode-pumped solid-state (DPSS) lasers have resulted in robust, production-capable systems. In the past, DPSS lasers were better suited for R&D use than for industrial production, but these advances have opened up a wide range of possible applications that include IR, pulsed, continuous-wave, and Q-switched, with many pulse widths in between. The robust DPSS lasers offer significant flexibility in terms of pulse shape, repetition rate, and beam quality, while harmonic generation allows a user to obtain shorter wavelengths suitable for a wide range of materials-processing applications (see Fig. 1).

FIGURE 1. Scribing with UV lasers has emerged as an alternative method of scribing semiconductor wafers for separation.

We have extensive experience with DPSS and excimer lasers in our job shop. The choice of laser is application-dependent and entirely related to beam characteristics. An excimer laser, for example, delivers a larger beam with relatively low repetition rate (typically less than 1 kHz), which we use for large-area patterning. Excimers produce high pulse energies with moderate pulse rates. Typically, the DPSS lasers we use are vanadate (Nd:YVO4)-based and produce an IR beam at approximately 1 µm that can be doubled (to green), tripled (to near-UV), or quadrupled (to deep-UV) with harmonic generators.

Cost of photons

While it is more expensive to produce photons with UV DPSS lasers than with excimer lasers, the advantages of UV DPSS lasers—higher processing speed, better flexibility, beam-usage efficiency, and high yields—can offset the cost differences in applications such as wafer scribing or small-hole drilling. Applications for which excimer lasers continue to excel include flood-beam exposure in annealing and large-area patterning using near-field mask imaging with effective beam homogenization.

A 100-W excimer laser, for instance, can be run at about 60 W. The average laser cost is about $140,000 for 100 W, yielding a per-watt-of-output cost of approximately $2300. By comparison, a 266-nm DPSS system costing $130,000 and delivering 2 W actually costs $65,000 per watt. Hence, an excimer laser is by far the least expensive source of UV photons. To flood a wafer with photons to remove massive amounts of material, the excimer would clearly be the more cost-effective system. But to dice the same wafer, one can go down to a 5-µm-wide line instead of using a 15-µm-wide line and can decrease the cost of UV photons by a factor of three (see Fig. 2).

FIGURE 2. A 5-µm laser line provided by a DPSS laser can be three times more efficient in terms of photon usage than a 15-µm line that might be obtainable from an excimer laser without the addition of expensive focusing optics.

If the excimer beam cannot reasonably focus to a 5-µm spot without expensive optics, while the DPSS laser with less-expensive optics can, the 2-W DPSS laser is the practical equivalent of a 6-W excimer. And if the 6-W excimer is in reality a 60-W system used 10% of the time, then the DPSS laser is more cost-effective in this application.

In the mid-1990s, we started using excimer lasers to dice blue-LED wafers and sapphire wafers for spacecraft components. In 1998–1999, we were producing three wafers per hour with an excimer system using 25% of the laser beam. A fairly complicated optical system geometrically divided, optimized, and refocused the beam onto the wafer.

During the past 18 months, we have found reliable 266-nm short-pulse DPSS lasers—we typically use both 355- and 266-nm—and throughput has jumped to more than eight wafers per hour. Now we routinely ship systems with DPSS lasers that are dicing 8 to 10 wafers per hour because of our ability to use the DPSS laser light effectively.

When a DPSS laser is properly optimized for an application, it has a very focusable beam that allows the user to get a lot of energy into a small spot. Consequently, processing tasks, such as machining a groove, are performed efficiently. The brightness of the DPSS laser beam—a very bright laser will focus to a smaller spot and drill a deeper hole or slot—means that less power is needed compared to a lower-brightness laser that has difficulty focusing to the same spot size.

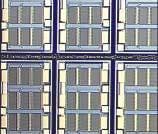

FIGURE 3. The pattern-writing capabilities of DPSS lasers provide useful flexibility in scribing varying wafer geometries.

In the case of wafer scribing, or the scribing and cutting of hard materials, the DPSS laser can penetrate the material more effectively in a smaller area. The DPSS laser is typically used at the focal point of the imaging lens, whereas with the excimer, a pattern is imaged. Because the user is actually writing the pattern with a spot, there is greater flexibility and control to contour shapes and go around corners, for instance. With an excimer laser, we would focus it into a line beam and scribe in one direction, essentially a less flexible configuration (see Fig. 3).

Shorter-pulse preference

We use DPSS lasers to machine ceramic, sapphire, all of the II-VI materials, gallium nitride, gallium arsenide, indium phosphide, gallium phosphide, and polymers. When doing so, we must avoid heating the part, because at very high repetition rates, power densities can be very high and heating increases. We have developed several techniques to get the processing done quickly, while keeping heat out of the part that is being processed.

Two specific factors—power density and energy density—are of primary importance. Power density essentially asks: "how many pulses per second are you hitting this part with?" Energy density is a function of how tightly the beam is being focused. Even using UV, thermal overloading can still occur. Short-pulse DPSS lasers create a smaller heat-affected zone in materials processing while providing more processing control. The number of pulses determines cutting depth. The high brightness of the short-pulse laser provides several advantages for fast processing.

The shorter-pulse UV DPSS lasers take advantage of a multiphoton absorption process. If we can produce more photons in a shorter period of time, it is more likely that they will add up and remove material simultaneously. The lasers we use are in the 5- to 15-ns range, while most commercially available DPSS lasers are in the 20- to 100-ns range. We are also exploring picosecond and femtosecond systems.

Better lasers now available

Recent advances in DPSS-laser technology and capabilities, as well as improvements in robustness and reliability, have given us the impetus to adopt them for job-shop use.

Almost all of the lamp-pumped solid-state lasers have issues regarding the ability to change repetition rates and the ability of all the solid-state crystal materials to thermalize, which means that the beam quality changes dynamically. The advantage of the newer solid-state lasers is that they're pumped monochromatically with laser diodes such that less heat is distributed to the laser rod. The user obtains a more focusable beam, and these newer lasers have very high reliability, on the order of 7500 to more than 10,000 hours of lifetime. High reliability is significant, especially compared to an excimer laser that needs servicing, including cleaning optics and changing gases, after every 100 hours of operation.

Some of the DPSS lasers that we used for many years had excellent beam brightness, but they were limited to low repetition rates of less than 100 Hz—typically less than 50 Hz. Their low speed limited the amount of processing that could be done, but they were effective for hole drilling and certain other kinds of processing. They delivered excimer-like, low-heat results, with the added advantage of the tightly focusable high-beam brightness. Most of these lasers were scientific-grade, not industrial, and thus there was a risk involved in putting them into a production environment.

When industrial-grade, 266-nm DPSS lasers became available, we did extensive testing and worked with the laser companies to get lasers that meet our expectations for industrial usage. The lasers must be housed in rugged industrial packages that would be easy to integrate and would provide a long-life, low-maintenance, high-precision process that doesn't require changing lamps, cleaning crystals, changing optics, or changing the gases or the windows.

In addition, we have been able to engineer our beam-delivery systems to take advantage of the lower power to increase the throughput of the process by using the beam more effectively. But there are still issues with these lasers. Because they run at 10-, 20-, 40-, and 60-kHz duty cycles, heat can build up in the part. Much work still needs to be done to determine how best to utilize these lasers without melting and welding the materials back together. Typical techniques involve moving the beam very rapidly. We have also integrated air-bearing stages into our DPSS system to deliver the needed accuracy and speed.