Solid-State Lasers: Ultrafast scientific lasers undergo an industrial revolution

Historically, companies manufacturing scientific ultrafast lasers have focused almost exclusively on achieving leading-edge performance (like high peak power or short pulse duration), often using advanced and therefore less-proven designs. In contrast, industrial lasers have long been designed for a cost-conscious environment, in which operational simplicity and reliability are of paramount importance and throughput, cost per part, percentage of up-time, and cost of ownership are key performance metrics.

This dichotomy has led to very different design philosophies for scientific and industrial lasers. Recognizing that productivity and cost of ownership (or "cost of data") are also very important for scientific users, the application of some central concepts from the industrial world is now yielding lasers for scientific applications that offer cutting-edge performance, industrial-grade reliability, up-time, and productivity.

Simplicity/performance tradeoff

In the world of ultrafast lasers, innovations have flowed in a single direction: from scientific to industrial products. Unlike 15 to 20 years ago, very few scientific users now bother to design and build a laser tailored for their experimental needs. Nevertheless, commercially available lasers for science had to strike a difficult compromise between increasingly demanding specifications and design reliability—a compromise long-tolerated as an inevitable matter of course by academics and other researchers.

The laser industry has responded by offering customer-friendly mitigations like long-term service contracts, rapid-response field service, local- and/or customer-owned spare-part inventory, and advance replacement. Still, guaranteed repair costs and minimized repair times are not enough on their own. After years where the (direct and indirect) cost and complexity of performing research have increased, researchers would much rather have a laser that does not fail at all rather than one that is easy and fast to repair.

To address this need, laser manufacturers are pioneering the development of scientific lasers that benefit from their industrial laser knowledge and experience. The flow of expertise between the two areas is finally becoming bidirectional, leading to an "industrial" revolution in scientific lasers. Specifically, we are now seeing the development of next-generation scientific lasers that feature both leading-edge performance and rugged industrial reliability. Current examples can be found in ultrafast oscillators and ultrafast amplifiers.

For oscillators, the big traditional tradeoff has been between minimum pulse width and operational simplicity, with the demand for shorter pulses being driven by better temporal resolution in advanced femtosecond experiments; the implicit rule of thumb was, "The shorter the pulse width, the more hands-on the laser." This rule has now changed with lasers that produce sub-8-fs pulse widths from sealed-box oscillators.

For amplifiers, the traditional tradeoff has been between peak power and operational simplicity; achieving shorter pulse widths and/or higher pulse energies have always required frequent operator intervention. In contrast, newer amplifiers incorporating industrial-derived design incorporate sealed oscillators as well as sealed stretcher/compressor units and can, for example, deliver 6 mJ per pulse with pulse widths of 35 fs or less. Stretcher/compressor units have previously been the most sensitive part of an ultrafast amplifier system, with performance sensitive to air movement, minor temperature drifts, and spurious misalignments.

Better lasers through volume statistics

The key to improved laser reliability and hands-free operation is a thorough understanding of all the reasons a laser drifts from optimum performance, suffers sudden performance failure, or degrades too quickly over its lifetime. To gain this understanding, extensive operation of components and complete lasers under environmentally stressful conditions at the R&D and prototype stage is required, followed by failure analysis leading to iterative design improvement. This also requires analyzing field performance at multiple prototype customer sites because there is no easy substitute for real-world operating experience.

One of the challenges facing manufacturers of high-end scientific lasers is low volume. While original-equipment manufacturers (OEMs) might use hundreds of units of a specific industrial laser, a typical research group will order one laser system just once every several years. With relatively few units in the field, meaningful failure and performance statistics are hard to come by for scientific lasers. Our approach to this problem is to analyze historical data from our installed base of many industrial lasers. While this does not address specific problems with particular scientific lasers, it provides feedback on issues that are fundamental to improving laser operation.

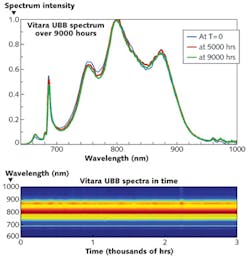

A few ultrafast laser applications have led to a market unit volume large enough to enable comprehensive statistical analyses of optomechanical misalignments and material degradation or creeping that can compromise the performance over extended usage in changing environments. These applications include femtosecond lasers used for multiphoton excitation (MPE) microscopy or semiconductor wafer analysis.

Highly accelerated life testing

In highly accelerated life testing (HALT), a product is tested to the failure point to determine the margin between the design strength and the use-condition stress, with the intent of ensuring that this margin is as large as is practical. The other major goal of HALT is to identify and understand the "physics of failure" (PoF) to guide design improvements and to verify that they are effective.

An important part of HALT is to avoid "artifact" failures due to excessive and unrealistic brute force, while accelerating failure modes that are realistic in order to allow their discovery in hours rather than months or years. The final outcome of HALT is to develop an effective production screen or highly accelerated stress screen (HASS) that weeds out product manufacturing weaknesses without decreasing the useful life of the units that are shipped to customers.

This HALT/HASS methodology is a widely used overarching strategy that is well-established in other industries where product reliability and lifetime are paramount concerns. It is also the basis on which Coherent now builds and tests next-generation scientific lasers to the highest possible reliability levels.

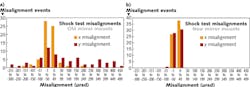

An example of HALT is an analysis of the variation seen in the degree of misalignment for a large number of optical mounts considered for use in one of our ultrafast oscillators (see Fig. 1). For the original design, most of the mounts showed only very small shifts in the x and y axis positions, although a significant population of mounts clearly showed much larger misalignments. As a result of these experimental findings, a mount redesign was initiated. Alignment tests were repeated after each design cycle to quantify the stability of the design across a population. For the same stresses, those new mounts now exhibit only minor misalignments.

Applying HALT to entire laser assemblies is arguably even more important and insightful as a development tool in guiding the design process. With a new laser design, such as with an ultrafast oscillator, HALT puts a laser through increasingly high levels of thermal and random vibration stresses—first separately and then in combination. Whenever a failure occurs, a root-cause determination is performed to provide quick feedback to the design team. Failures typically involve issues related to design understanding and choices, materials and component selection, and/or design for manufacturability issues.

Highly accelerated stress screens

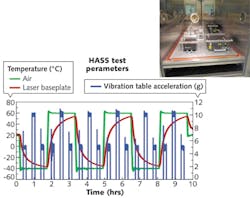

Once the design reaches pilot production stage, a HASS is developed as part of the manufacturing process to measure and control sources of variation in order to reduce reliability problems (see Fig. 2). The screen is devised to find the weak part(s) of the laser that may be due to workmanship and/or supply chain shifts and allow for a closed-loop quality-control process for quick feedback to the supply chain when failures occur. For example, ultrafast-oscillator heads are subjected to several hours of intense thermal cycling and vibration stress testing.After each ultrafast-oscillator head is fully assembled and aligned, meets internal specification, and its ultrafast resonator cycled through a temperature and vibration profile, each optical mount is tapped with a calibrated force (higher than a 10 g shock) and the output power measured again. Following this step, the laser head is cycled again (between -10 and +60°C) and must perform to specification without any realignment.

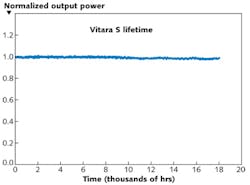

For a conventional life test, the laser is run without opening the laser head for cleaning and without any realignment (see Fig. 3). This laser is operated in constant-pump-power mode throughout the test because this operating mode better shows the laser's optomechanical stability; this mode is in contrast with the industry-typical practice of showing ultrafast laser performance in a light feedback loop, where the pump power is increased over time to compensate for deteriorations in cavity cleanliness or alignment.By using feedback from HALT/HASS protocols along with data from large numbers of workhorse lasers operating in demanding 24/7 industrial applications, next-generation scientific ultrafast lasers are now combining cutting-edge performance with industrial reliability and throughput.

About the Author

Allan Ashmead

VP of Research Laser Systems, Coherent

Allan Ashmead is VP of the Research Laser Systems business unit at Coherent (Santa Clara, CA).

Steve Butcher

Scientific Marketing Manager, Coherent

Steve Butcher is scientific marketing manager at Coherent (Santa Clara, CA).

Marco Arrigoni

Marco Arrigoni is vice president of marketing at Light Conversion (Vilnius, Lithuania). He previously served as director of marketing at Coherent (Santa Clara, CA) from 2007 through 2023.