In addition to the numerous functional uses of perovskite as a photovoltaic material, a photodetector, a piezoelectric actuator, a metamaterial lens, an LED, and a vertical-cavity surface-emitting laser (VCSEL), researchers at the University of Toronto (ON, Canada) have demonstrated the first perovskite-based spherical resonator laser by coating organometallic halide perovskites uniformly onto glass microspheres.

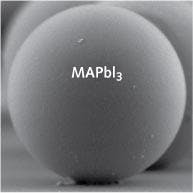

These organometal halide perovskites are an emerging class of semiconductors that have the formula CH3NH3PbX3, where Pb is lead and X can be iodine, bromine, or chlorine (C is carbon and H is hydrogen). Using atomic-layer deposition (ALD), the team grew one-atom seed layers of lead sulfide (PbS) and then “exchanged” these PbS layers with perovskite by exposing them to iodine (I) gas vapor and methylammonium iodide. The highly pure, polycrystalline film of CH3NH3PbI3 (also called MAPbI3) perovskite was then coated onto a spherical optical cavity made from a glass microsphere that lases when pumped with blue light. The structure lases at a threshold of around 65 μJ/cm2 and shows a net optical gain of about 125/cm with a gain bandwidth of ~50 meV, comparing well to standard microsphere lasers. These so-called conformal perovskites could be used to make on-chip “whispering gallery mode” coherent light emitters and also show promise in light harvesting and water-splitting devices. Reference: B. R. Sutherland et al., ACS Nano 8, 10, 10947 (Oct.14, 2014).