Fiber Lasers: Ultrafast fiber lasers reach millijoule energies with PC and LMA fibers

JIAN LIU

The millijoule (mJ) energy level has long been conceived as a barrier for all-fiber-based femtosecond fiber lasers to competitively penetrate into such mainstream markets as metal, semiconductor, and glass micromaterials processing—for decent throughput in production, 0.2 mJ or better pulse energies are needed. PolarOnyx has overcome this barrier with the recent development of the what we think is the world's first millijoule-level femtosecond ultrafast fiber laser with 100 kHz repetition rate using a 100 W photonic-crystal fiber (PCF) amplifier. We have also developed what we think is the world's first kilowatt average power using a large-mode-area (LMA) fiber amplifier.

Breaking these performance barriers presents new opportunities for high-energy and high-power femtosecond-scale ultrafast fiber lasers in high-energy physics and micromaterials processing applications due to their compactness, low maintenance, cost-effectiveness, and reduced energy consumption.

Energy scaling

An ideal high-energy and/or high-power ultrafast fiber laser typically includes an all-fiber-based seed oscillator, stretcher, and amplifiers. Connection between such components as fiber combiners, gain fiber, and isolators is usually accomplished through fusion splicing for robust operation; therefore, free-space component use should be minimized. However, due to difficulties in handling the nonlinearities accumulated in optical fibers and fiber amplifiers, energy scaling in all-fiber designs has proven challenging (compared to hybrid approaches), and experimental demonstration has been limited to low hundreds-of-microjoule energies and only 100 W power levels.1,2

The ability to scale our all-fiber-based femtosecond fiber laser system to achieve pulse energy above 1 mJ and average power above 1 kW depends on a reverse-pumping scheme and both PCF and LMA optical fiber amplifiers.3 Large mode-area diameters for PCF along with highly doped ytterbium (Yb) ions mitigate the nonlinearity and enable energy scaling to the millijoule level. In addition, large numerical apertures (>0.5) for the inner cladding of PCFs allow more pump power to be injected into the fiber.

Millijoule energy

To achieve high energy at a nominal 1 μm operating wavelength, we use a 50 μJ seeding laser, a high-energy amplifier, and a pulse compressor (see Fig. 1). The seeding laser is our Uranus series 1 μm high-energy mode-locked femtosecond fiber laser that outputs stretched pulses with pulse durations around 1.2 ns. The laser repetition rate is tunable between 100 kHz and 2 MHz with a maximum output power of 5 W. For Uranus, the highest pulse energy is 50 μJ at a repetition rate of 100 kHz.

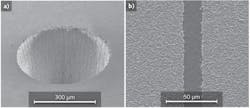

The active medium in the energy amplifier is an 80 cm-long, single-mode, ytterbium-doped, polarization-maintaining (PM), rod-type, large-mode PCF from NKT Photonics (Birkerød, Denmark). It has a core diameter of 100 μm and a pump cladding diameter of 285 μm. The collimated seeding laser beam first passes an isolator and is then focused and injected into the PCF by a spherical lens with a focal length of 35 mm.

For the reverse-pumping scheme, up to 174 W of pump power at 976 nm is injected from the opposite end of the PCF. The pump beam is delivered by an optical fiber with a core diameter of 242 μm. The pump beam is collimated and then re-focused into the gain medium using two aspherical lenses with focal length of 11 mm. Multiple dichroic mirrors are used to protect the pump laser diodes from any possible damage due to high-peak-power signal wavelengths. The overall isolation is greater than 30 dB for a signal wavelength in the experimental setup, and no extra cooling method is applied to the PCF rod.

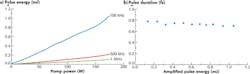

Operation of the femtosecond laser at 100 kHz, 500 kHz, and 1 MHz repetition rates produces about 105 W of output power with an optical slope efficiency of 68%. At a 100 kHz repetition rate, up to 1.05 mJ pulse energy is achieved and M-squared (m2) values are 1.17 (parallel) and 1.27 (perpendicular).

After compression of the output beam in a grating pulse compressor with 95% grating efficiency, a pulse duration of 705 fs is measured at the maximum amplified pulse energy of 0.85 mJ. By improving the grating efficiency to 98%, compressed 1 mJ pulse energy is readily achieved (see Fig. 2). The pulse compressor was optimized for the highest pulse energy; without tuning the compressor, the pulse duration varied slightly between 700 and 800 fs at all amplified pulse energy levels. By further increasing the pump power and controlling thermal issues, femtosecond pulses with higher pulse energy (multi-millijoules) can be achieved.Kilowatt power levels

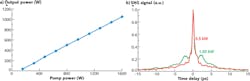

Again using our Uranus series nominal 1 μm (1064 nm central wavelength at a repetition rate of 69 MHz), 50 W seed laser, our experimental setup includes an 8-m-long, PM, double-clad LMA fiber—the Nufern (East Granby, CT) PLMA-YDF-30/400 with 30 μm core diameter (see Fig. 3). This gain fiber is pumped by 976 nm diode lasers with a total pump power of 1600 W in a bi-directional pumping scheme that injects 800 W into each end of the gain fiber. A small portion of the output beam is reflected by a fused silica prism for output characterization.A small portion (3.4%) of the output power was reflected by a fused silica prism and sent to a grating compressor to perform pulse compression. With pulse width optimized to around 800 fs at both 0.5 kW and 1.05 kW amplified power levels, m2 at the highest output power was measured to be 1.117 (parallel) and 1.120 (perpendicular).

Our commercially available femtosecond fiber lasers currently reach 0.5 mJ pulse energies-increasing throughput 10X compared to 100 μJ systems in glass hole drilling and thin-film scribing applications (see Fig. 5). However, 1 mJ products are near production, and we continue to work toward 10 mJ and beyond energy levels for wavelengths from 1 to 2 μm and as high as 2.8 μm.4,5 These air-cooled lasers consume a physical footprint of 43 × 13 × 56 cm for the mainframe and 31 × 120 × 15 cm for the optical head.We expect that ultrafast fiber lasers will dominate the micromaterials processing market in 5 to 10 years and find unprecedented applications not yet imagined. For example, the IHS Electronics & Media (E&M) 2013 report estimates that the flexible display market will grow to $1.3 billion in 2016 and grow rapidly to $67.7 billion by 2023-a total of 1.8 billion units that will comprise about 25% of the total flat-panel display market. Ultrafast femtosecond lasers are ideally suited to processing flexible display materials. And as high-energy physics facilities get bigger and more costly, less-expensive and more compact ultrafast lasers will be critical.5,6

REFERENCES

1. L. Shah et al.,Opt. Exp., 13, 12, 4717–4722 (2005).

2. J. Liu and L. Yang, "ns and fs fiber lasers," FILAS 2011, Turkey (Feb. 16-18, 2011).

3. P. Wan et al., Opt. Exp., 21, 24, 29854–29859 (Nov. 2013).

4. P. Wan et al., Opt. Eng., 53, 5, 051508 (2014).

5. P. Wan, L. Yang, and J. Liu, "Towards high power and high energy femtosecond fiber lasers," SPIE Photonics West, San Francisco, CA, paper 8961-19 (Feb. 3-6, 2014).

6. G. Mourou et al., Nat. Photon., 7, 258–261 (2013).

Jian Liu is president of PolarOnyx, 2526 Qume Drive, Suites 17 & 18, San Jose, CA 95131; e-mail: [email protected]; www.polaronyx.com.