Lithium niobate fills blue laser window, for now

The race to develop reliable blue-emitting diode lasers notwithstanding, Matsushita Electric Industrial (Osaka, Japan) plans to get its blue and green laser light from periodically poled lithium niobate (LiNbO3) doped with magnesium oxide (MgO), according to Kazuhisa Yamamoto in the optical disk development center at Matsushita. The company discussed its plans to use magnesium-oxide-doped periodically poled LiNbO3 (PPLN) in high-density (15 Gbit/side) 12-cm digital video disks (DVDs) at the MORIS/ISOM `97 conference (October 27-31) in Yamagata, Japan, and at the IEEE/LEOS 1997 annual meeting (San Francisco, CA) November 10-13, 1997.

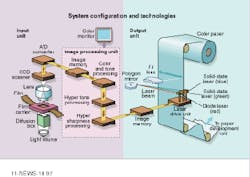

At Fuji Photo Film (Kanagawa, Japan), the MgO:LiNbO3 frequency conversion crystals are in use in a digital photoprinting system (see figure) and a fluorescent image analyzer that were introduced to the Japanese market in June and December, respectively, of 1996, according to Akinori Harada in the Miyanodai Technology Development Center at Fuji.

These products all take advantage of work published by researchers at Waseda University (Tokyo, Japan) in which MgO doping was used to increase the resistance of LiNbO3 to optical damage caused by the photorefractive effect. Using MgO:LiNbO3 crystals, the Waseda University researchers were able to induce polarization inversion for the first time by applying an electric field at room temperature.1

The red-green-blue (RGB) laser scanning optical system in Fuji`s digital photo printer uses red, green, and blue laser light sources at 688, 532, and 473 nm to match the spectral sensitivity of the color photographic paper. While stable red diode lasers are available commercially, Fuji engineers had to develop their own stable green and blue sources using available diode lasers and MgO-doped PPLN as the wavelength-converting element.

Sunao Kurimura, a coauthor of the work at Waseda University and currently a visiting professor at Stanford University (Palo Alto, CA), discussed these commercial applications in September at the annual affiliates meeting of the Center for Nonlinear Optical Materials (CNOM) at Stanford.

Comparing the current PPLN capabilities to the blue lasers developed by Shuji Nakamura and colleagues at Nichia Chemical Industries (Anan, Japan), CNOM director Robert Byer said the blue-emitting lasers still must pass through a development curve before their reliability and coherence will be suitable for tasks such as reading and writing compact disks.

In the international race to develop commercial levels of reliability for blue diode lasers, Nakamura`s team reported achieving 300 hours of reliable operation in August and more than 1000 hours in September.2,3

Matsushita, however, has already reached lifetimes of "several tens of thousands of hours" for a prototype digital video disk laser that produces blue light through second-harmonic generation using periodically poled MgO:LiNbO3. The lifetime quoted for this PPLN device was measured at 80°C and would actually be much longer at room temperature, according to Kurimura.

Despite intense effort and rapid progress in the diode-laser effort, it will still take some time for that technology to catch up. "There`s a small window available," Byer said. "It may be a three-year time window, where the doubling of red diode lasers to get to the blue looks more promising technically than building a blue diode laser."

Considering the size of the DVD market, which Yamamoto estimates at $10 million to $100 million per year, it is not hard to understand why Matsushita and Fuji have decided to climb into the blue laser window now, using available technology.

REFERENCES

1. A. Kuroda, S. Kurimura, and Y. Uesu, Appl. Phys. Lett. 69(11), 1565 (Sept. 9, 1996).

2. S. Nakamura et al., Jpn J. Appl. Phys. 36, Part 2, No. 8B, 1059 (15 Aug. 1997).

3. S. Nakamura, Proc. ISCS-2X, San Diego, CA (Sept. 8-11, 1997).

About the Author

Hassaun A. Jones-Bey

Senior Editor and Freelance Writer

Hassaun A. Jones-Bey was a senior editor and then freelance writer for Laser Focus World.