Laser metal deposition (also called laser additive welding or laser cladding) is becoming more common for such industrial applications as repair of damaged or worn turbine blades. However, circular laser-beam profiles can cause uneven and excessive heating of the metal at the center of the beam as it scans across the work surface, resulting in increased porosity, migration of constituent alloy materials, large grain growth, and residual stress. To combat these undesirable effects, researchers at Loughborough University (Loughborough, England) have demonstrated the use of computer-generated diffractive optical elements (DOEs) to customize laser-beam intensity profiles and reduce the temperature gradient across a metal work surface to eliminate excessive heating.

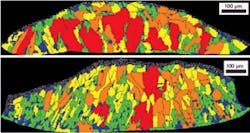

Deposition experiments were completed using a standard 1.2 kW CO2 gas laser with a Gaussian TEM00 beam profile (top) and alternatively, by reflecting the standard beam profile off of a customized “Rugby Posts”-shape DOE designed to provide more consistent heating across the irradiated region (bottom). Analysis of the two deposition regions via electron backscatter diffraction–a process in which electrons strike the crystalline planes of a sample placed in a scanning electron microscope chamber to image its internal structure as the electrons fluoresce on a phosphor screen–show a 50% reduction in grain sizes, leading to a deposition with improved mechanical properties on the DOE-deposited metal. Contact Matt Gibson at [email protected].