Optically locating a QD allows photon-extraction grating to be properly positioned

Individual quantum dots (QDs) that produce single photons on demand are useful for quantum information science applications, and self-assembled, epitaxially grown QDs have the highest optical quality. However, when these QDs are fabricated, they can come into existence at any point across the epitaxially grown film’s area—and they can be very difficult to locate. Researchers from the National Institute of Standards and Technology (NIST; Gaithersburg, MD), the University of Maryland (College Park, MD), the University of Southampton (Southampton, Hampshire, England), and the University of Rochester (Rochester, NY) have developed a way to quickly locate a QD and then lithographically create a photon-extracting grating around it.

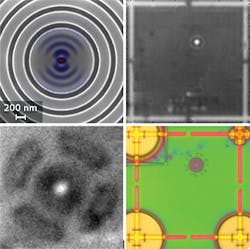

After growth, a 10-nm-diameter indium arsenide/gallium arsenide (InAs/GaAs) QD is located via photoluminescence imaging relative to metallic alignment marks (see figure, upper right). The imaging setup contains two LEDs—one to activate the QD and the other to simultaneously illuminate the alignment marks at a different wavelength. A camera images the 100 × 100 μm region within the alignment marks. The position of the QD is determined to an average position uncertainty of less than 30 nm or, if a solid-immersion lens is used for imaging, less than 10 nm. This allows the researchers, when they later lithographically fabricate a circular grating (see figure, top and bottom left) around the QD, to center the QD in the grating for best performance. In other words, the grating is placed at the QD (see figure, bottom right) rather than the other way around. The result, for a 0.4 numerical aperture collection lens, is a 48%±5% collection efficiency—close to the theoretically predicted 50% value. Reference: L. Sapienza et al., Nature Commun. (2015); doi:10.1038/ncomms8833.

About the Author

John Wallace

Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.