Multicolor Lasers: Semiconductor laser can produce many colors, including white

Laser light that looks white to the human eye can be created by combining light from separate red, green, and blue lasers. Such an output stimulates all three of the different types of photoreceptors in the eye and, if correctly balanced, results in the desired white appearance. From there, any or all of the lasers can be separately adjusted in intensity to create any saturated or nonsaturated color. This technology has been around for decades in the form of laser light shows.

Creating a microscopic white laser that could emit red, green, and blue light in varying ratios could lead to bright and efficient displays with a white laser for each pixel. While conventional semiconductor lasers can serve as miniature light emitters, they can only emit one wavelength and would thus be suitable only for monochrome displays.

Researchers at Arizona State University (Tempe, AZ) and Tsinghua University (Beijing, China) have recently developed a true white-light semiconductor laser with a lasing cavity only 28.0 × 18.0 × 0.3 μm in size.1 The cavity, which is optically pumped, emits light of different colors from different cavity regions and can be pumped independently and simultaneously by three different focused laser spots to produce white or colored light. The researchers are working on future electrically pumped versions.

Monolithic laser

The laser itself is a one-piece, multisegment zinc cadmium sulfide selenide (ZnCdSSe) nanosheet in which the mix of Zn, Cd, S, and Se is different in each segment. The researchers developed their own approach to chemical vapor deposition (CVD) fabrication that allowed separate control of the chemical makeup and structure (and as a result, the bandgap) of each segment, so that the emission wavelength varies as a function of position.

Although the devices are carefully crafted one at a time, the potential is there for larger-scale production, according to Cun-Zheng Ning, one of the researchers. “This is an issue we have thought about a lot,” he says. “Yes, in principle, we can do large scale. This requires some careful calibration of the growth and the patterning of the substrate. We also need a more commercial-grade CVD system for more uniform growth over a large substrate.”

Images of the structure taken with a scanning electron microscope (SEM) show the structure to be about 60 μm long, up to 45 μm wide, and anywhere from 60 to 250 nm thick. Each segment in the structure is a single crystal with no detectable defects.

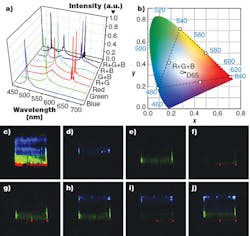

To create a laser cavity, a high-quality end facet was cleaved using the bend-to-fracture method, resulting (in one example) in a multicolor laser cavity 28 × 18 × 0.3 μm in size. To produce visible light of different colors and combinations, one or more areas of the structure were pumped with 9 ns focused pulses of laser light at a 355 nm wavelength (see figure).

The resulting individual red, green, and blue (RGB) spectral peaks lie at 642, 530, and 484 nm, respectively. A perceived white output very close to a CIE white standard is straightforward to produce with simultaneous RGB pumping. The three wavelengths mix well in the far field.

What is the most important future research planned? “Electrical injection,” says Ning. “The structure is now powered by another laser, as a proof of concept of our structure and demonstration of the quality of the materials. We need to immediately demonstrate that the same lasing can be done by a simple battery. This is the great advantage of semiconductors, since they can in principle be powered by a battery. This is also one of the reasons why we are pursuing a semiconductor-based approach.”

REFERENCE

1. F. Fan et al., Nat. Nanotechnol. (2015); doi:10.1038/NNANO.2015.149.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.