Gas Lasers: Carbon monoxide laser aims at high-power applications

While carbon monoxide (CO) lasers, which emit at wavelengths near 5 μm, have been around for decades, they have not been used nearly as much as the similar carbon dioxide (CO2) laser, which has a primary output wavelength of 10.6 μm. Now, Coherent (Santa Clara, CA) has unveiled a CO laser designed for materials-processing applications such as glass cutting, as well as medical, spectroscopic, and research uses.

“CO laser technology was developed in the mid-1960s at the same time as CO2 lasers,” says Andrew Held, director of marketing for Coherent’s CO2 business unit. “The CO laser was attractive because it had the potential to be two times more efficient than CO2 lasers. However, the CO laser presented challenges: Early CO lasers needed to be cooled to get high powers with high efficiency (very high power versions were actually cryogenically cooled) and the laser output power would degrade quickly. Typical lifetimes were tens of hours at most. Consequently CO2 laser technology ‘won’ and has been the gas-laser standard since.”

But Coherent has developed its own technological tweaks, enabling the design of CO lasers that operate at high output powers in the 5–6 μm range at high efficiencies at room temperature, and which last for thousands of hours, says Held. The new CO laser uses much of the same technology developed over many years for Coherent’s CO2 lasers; for example, the radio-frequency (RF) power-supply technology used in the company’s CO2 lasers can be applied to the CO laser.

Coherent has tested a number of different prototype CO lasers based on the company’s waveguide and slab architectures; laser output powers ranged from 20 W to more than 1 kW. The company’s first high-power CO laser, which will be shown at LASER World of Photonics (June 22–25, 2015; Munich, Germany) can operate in high-peak-power pulsed operation with average powers of 200 W and greater.

“There are many benefits when materials processing at 5 μm, the foremost of which is the light/material interaction advantage,” says Held. “The CO laser’s 5 μm output may have significantly different interactions compared to the CO2 laser’s 9 to 11 μm laser output, simply due to the different absorption coefficients. It has stronger absorption in many films, polymers, PCB dielectrics, ceramics, and composites. Very low attenuation of the 5–6 μm laser light in chalcogenide and heavy-metal fluoride fibers open the potential for fiber delivery. The inability to fiber-couple the output of CO2 lasers is a major disadvantage over fiber lasers.”

Glass cutting

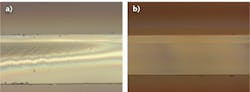

One application where this difference in absorption coefficient has a significant impact is glass cutting, Held explains (see figure). “In CO2 laser-based glass cutting, the 10.6 μm output is absorbed very strongly at the surface. The heat generated at the surface must then diffuse into the bulk material; subsequent water-jet cooling is then used to produce a thermal shock, which creates a scribe line in the glass. For thicker glass substrates, this is followed by mechanical breaking. The overall process is the same with the CO laser; however, the glass absorption of the 5 μm output is much lower. Thus, the light penetrates directly and further into the bulk material, inducing heating more evenly throughout the thickness of the glass.”

Held adds that testing has shown several important benefits, including no surface melting, no cracks, and zero residual stress in the glass. The result is a better quality cut, stronger glass, and a wider cut process window.

The CO laser also enables radial (freeform) glass cutting; in contrast, CO2 lasers can only produce straight line cuts because the inherently round output beam must be reshaped into a long, thin line beam to distribute the heat generated at the surface. Curved cuts are particularly important in smartphone display applications, because curved corners or shaping to accommodate buttons and controls are often required. Curved and free-form cuts are possible with the CO laser, where the round beam penetrates directly into the glass without adverse heat effects caused by the difficult to control diffusion process. In addition, the CO laser’s shorter wavelength leads to a smaller focused spot than that for a CO2 laser, and/or a larger depth of focus for the same given spot size; a larger depth of focus leads to a larger process window, allowing a larger field of view for area processing.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.