Ultrafast Lasers: Ultrashort pulse lasers bring cost-efficient precision to micromanufacturing

MICHAEL MIELKE

Ultrashort pulse (or ultrafast) lasers are optimum tools to machine, reshape, weld, or otherwise modify a multitude of materials when the required precision approaches one micron. Conventional lasers focus energy in space and wavelength to achieve greater precision and cost-efficiency than mechanical tools, or plasma or electrical discharge erosion. Ultrashort pulse lasers add temporal focus of the energy to dramatically change the light-matter interaction.

Typical benefits of using ultrashort pulse lasers in micromachining include enhanced dimensional accuracy and tighter tolerances, reduced collateral damage, and elimination of post-processing steps. These lasers exploit either thin disk or fiber optic architectures to enable high-power output, with pulse duration in the range of picoseconds to femtoseconds. Although this equipment tends to cost more initially, the substantial improvement in process precision can enable new designs, reduce overall time, and lower operating cost for the production line. Consequently, ultrashort pulse lasers have become essential manufacturing tools in the automotive, medical device, and consumer electronics industries (see Fig. 1).

Need for precision

High-value products such as smartphones, automobiles, and medical devices are designed to a dimensional precision that was impractical to manufacture cost effectively a few years ago. The benefits of precision are evident: tougher, lighter-weight electronic devices; more fuel efficient, lower-pollution cars; and more functional reliable medical devices.

For example, the transparent cover plates used to protect smartphone and tablet touch screens or camera lenses are cut with precision from sheets of strengthened glass or sapphire because of the hardness and scratch resistance of these materials. After cutting, the plates must not have any pattern deviations, cracks, or chips larger than about 10 μm anywhere along the cut edge in order to survive subsequent manufacturing steps as well as the physical impacts of consumer handling.

With the mechanical force of diamond saws, or the heat associated with conventional laser techniques, the cutting process involves uncontrolled brittle fractures that leave jagged edges and large defects. These have typically been removed by a sequence of grinding and polishing steps after cutting.

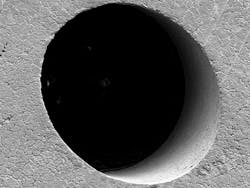

In contrast, cutting glass and sapphire with an ultrashort pulse laser leaves the edges free from large defects since there is no mechanical force or heat diffusion in the process. The need for grinding and polishing is eliminated because the cover plates are cut to design specification directly by the laser process. Moreover, the ultrashort pulse laser process can create features in brittle materials that are impossible using mechanical tools, such as orifices <100 μm in size, thereby enabling entirely new design options for personal electronics (see Fig. 2).Achieving design precision, part after part, is essential in high-production, high-volume environments. Since the performance of high-value products depends directly on the ability to accurately match design tolerances, any lack of repeatability on the production line means product performance variation, unit to unit. Whether it results in unmet consumer expectations or unmet government regulatory standards, uncontrolled product variation is a serious problem for many novel product technologies.

The new generation of automobile fuel injectors, known as gas direct injectors (GDi), is an example of the need for determinism in precision manufacturing. One major factor in engine performance is the spray pattern generated by each fuel injector within the engine cylinders. Both the amount of fuel sprayed and the distribution of fuel droplets in the cylinder govern combustion dynamics and, ultimately, how fuel efficient and powerful the engine will be. Consistent fuel injector performance demands spray hole diameter tolerance as tight as ±1 μm along with well-defined edge break.

Previously, GDi spray holes were drilled through the high-carbon steel injector housing using electrical discharge machining (EDM). The hole diameter tolerance for a large sample of injectors using the EDM process is typically ±3 μm due to the stochastic nature of electrical erosion. This produces large spray pattern variation, injector to injector, and results in too much or too little fuel in the engine cylinder during each cycle—a major factor influencing engine performance.

The ultrashort pulse laser drilling process, on the other hand, removes a precise and consistent amount of material with each laser pulse, achieving a near-perfect spray hole. The depth removed with each laser pulse can be measured in the tens to hundreds of nanometers, depending upon the pulse energy setting. Laser drilling readily achieves the ±1 μm diameter tolerance within a cost-effective process time, typically <1 s per hole. Hence, every injector sprays the right pattern of fuel, and the engine meets all performance and emissions requirements (see Fig. 3).Total cost of ownership

When conventional laser processing steps fail to enable determinism at the micron level, extensive rework or post processing may be required. Also, parts may be rejected during final inspection, which severely impacts factory yield. Post processing often involves manual labor, caustic chemicals, and fine tuning of individual parts on the production line. Each of these imposes additional costs and may further reduce statistical yield. Thus, the total cost of ownership (per annum) for production equipment—including all post-processing steps—is the best point of comparison for precision manufacturing options.

A clear proof point is in the manufacture of cardiovascular stents, where a laser machining process is used to cut the stent's intricate lattice pattern from an extruded metal tube. The lattice strut width can be as narrow as 10 μm by design, and the patterns typically incorporate many sharp bends and flexure hinges. Conventional laser machining leaves a heat affected zone (HAZ) of varying thickness, as well as recast metal, that must be removed with post-processing before final polish and assembly of the stents. Manual de-burring and chemical etching are common methods of removing defects, and these impose recurring costs for skilled labor and materials.

In full production, ultrashort pulse lasers cut stents from an extruded tube with no appreciable HAZ or recast. This means manual de-burring and chemical etching can be eliminated from the manufacturing process, and stents move directly to the polishing stage. In addition, the ultrashort pulse laser process is portable from one type of metal and one stent size to another. The stent cutting machines can therefore serve production for multiple medical device product lines. Sharing or repurposing equipment offers dramatic cost of ownership savings for the medical device manufacturer (see Fig. 4).Laser-matter interaction benefits

When a burst of laser energy is incident upon a material, the focused electromagnetic field interacts with the electron population to cause acceleration, which imparts heat to the local lattice structure. When the laser wavelength is resonant with the lattice absorption spectrum, energy is rapidly absorbed. Moreover, the concentrated nature of laser light means the interaction is highly localized. These phenomena are common to all types of laser material interactions.

When the laser energy burst duration is long compared to the thermal diffusion time of the material (nanosecond pulse duration to continuous wave lasers), thermal equilibrium is achieved between the electron population and the lattice ions. Importantly, much of the heat imparted to the material diffuses outside the focus volume of the laser beam. Even though conventional laser material processing sustains much more focused energy delivery than other methods of machining, it still imposes substantial collateral damage to the substrate when examined on the micron scale. For precision manufacturing requirements, this scale is critical.

When the laser energy burst duration is short compared to the thermal diffusion time of the material (femtosecond to picosecond pulse duration lasers), there is no thermal equilibrium, and more importantly, there is no time for heat to diffuse outside the absorption volume of the laser pulse. This temporal focusing of laser energy creates a much more localized interaction where material is ionized, leading to ablation with minimal impact on the adjacent matter. Since the area surrounding the laser focus exhibits negligible heat affects, this process is often called "cold ablation."

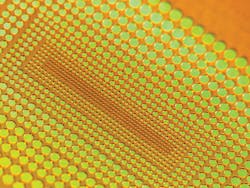

Some of the benefits of ultrashort pulse ablation include much more spatially selective material removal, lower dependence of material absorption on the laser wavelength, and machining of heat sensitive materials and structures—like plastics, glasses, semiconductors, thin films, and multi-material stacks—with negligible defects (see Fig. 5). The superior selectivity and apparently athermal nature of materials processing with these lasers is often counterintuitive to users of conventional laser machining systems. Nevertheless, the science of the light-matter interaction is rather well known.Industrial ultrashort pulse lasers

The benefits of ultrashort pulse laser materials processing were first identified more than two decades ago by researchers in academia and at national laboratories. Indeed, one of the first proposed applications of femtosecond lasers was machining of highly volatile materials used in military weaponry. Commercial applications of high-power ultrashort pulse lasers are much more cost sensitive, and only in the last five years have industrial laser systems reached the right cost, performance, and reliability combination to meaningfully impact high volume manufacturing.

Most high-power, industrial ultrashort pulse lasers are based on either thin disk or fiber laser architecture, owing to the thermal management advantages intrinsic to these gain media geometries. Compared to traditional laser crystal rods or slabs, the thin disk and fiber geometries have very high surface-area-to-volume ratio, meaning heat extraction is much faster and more uniform. The overall laser industry advancement of these general laser architectures over the past decade has simultaneously paved a clearer path for industrial ultrashort pulse lasers.

High-power, high-energy ultrashort pulse lasers all utilize an oscillator-amplifier laser architecture rather than a more simple, single-laser cavity. Femtosecond lasers further require chirped pulse amplification (CPA) to manage the extremely high peak power retained in their pulses. These architectural concepts impose more complexity on industrial laser design compared to more traditional lasers. Nonetheless, steady advancement and testing of ultra-short pulse lasers has produced practical industrial appliances for the manufacturing world, such as TRUMPF's TruMicro laser systems.

In practice, even ultrashort pulse lasers have limitations in precision. Every material and every part geometry has specific requirements that constrain the options for laser process parameters. Even femtosecond and picosecond laser pulses can impart a measurable amount of heat to a substrate when the average laser power is high enough, compared to the beam movement relative to the part. For example, each fuel injector spray hole is confined to a finite volume within the injector housing. Heat build-up will occur, and it will affect part quality at sufficiently high laser power level. You can only move the part or the laser beam so fast.

In general, higher laser power shortens the pulse width requirement for athermal machining. Why not use even shorter pulse lasers? At some point, laser beam delivery to the material becomes a limiting factor. For typical micromachining applications, with beams focused to the ~10 μm diameter range and pulse energy in the tens of microjoules range, compressing the pulse duration shorter than about 400 fs would lead to beam self-focusing. This assumes ambient atmospheric species (nitrogen and oxygen) at normal pressures for the Kerr contribution to refractive index.

In working with ultrashort pulse lasers, the process parameter space now incorporates additional options compared to traditional lasers. In more and more cases, the somewhat increased complexity is offset by the highly compelling benefits of materials processing with these lasers. Achieving the benefits of ultrashort pulse laser materials processing demands applications know-how beyond standard industry practices. The processes are more specialized, and it pays to work with an applications expert.

Michael Mielke is program manager at TRUMPF, Farmington, CT; email: [email protected]; www.us.trumpf.com.