Tunable Sources: Thulium-doped fiber MOPA pumps tunable mid-IR OPO

The mid-IR spectral region is home to the vast number of molecular absorption resonances that help identify organic and inorganic molecules. As a result, this spectral region has become the focus of sensing and remote sensing applications in the life sciences; the pharmaceutical, agricultural, and food sectors; security and forensics; and the military.

As a bonus, the mid-IR contains several low-absorption atmospheric windows that allow long-range sensing. In addition, because mid-IR light cannot penetrate into the eye, the region is considered eye-safe.

Crucial to the exploitation of the mid-IR is the development of broadly tunable light sources with high-enough peak power/energy to permit reliable spectroscopic measurements. One often-used approach is nonlinear frequency conversion of a source to the desired wavelengths using an optical parametric oscillator (OPO).

Pulsed fiber-laser sources for this purpose have traditionally been limited in pulse energy by optical nonlinearities in the fiber, which are worsened by the fiber’s tight confinement and required long length. To overcome this obstacle, researchers at the Townes Laser Institute at CREOL, University of Central Florida (Orlando, FL) are working with a novel fiber-based master-oscillator power-amplifier (MOPA) source containing a thulium (Tm)-doped single-mode fiber oscillator and two flexible Tm-doped photonic-crystal fiber (PCF) amplifier stages.1 The source is used to pump a zinc germanium diphosphide (ZnGeP2, or ZGP) OPO.

The 4-m-long polarization-maintaining oscillator has 10 and 130 μm core and cladding diameters respectively and is pumped with 35 W of light at a 793 nm wavelength from a laser diode; an acousto-optic modulator Q-switches the oscillator, resulting in 100 ns, 25 μJ pulses produced at a 20 kHz repetition rate.

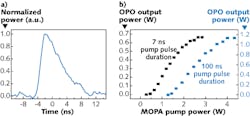

A 6.5-ns-long section of each fifth pulse (4 kHz rate) from the oscillator is selected by an electro-optic modulator to be amplified. The first Tm:PCF amplifier section is 2.7 m long and pumped with 100 W of laser-diode light at 793 nm; the second section is 1.4 m long and can be pumped with up to 300 W of light at 793 nm from laser diodes (although a pump power of 45 W was finally settled upon due to melting of the PCF’s polymer coating). The resulting pulses fed into the OPO have an energy of about 0.84 mJ, a 10 dB linewidth of less than 1.8 nm centered at 1980 nm, and a 7 nm duration with an asymmetrical shape (see figure), resulting in a peak power of about 121 kW.

The OPO has a doubly resonant oscillator (DRO) and a 20-mm-long split-reflectivity DRO cavity; a 4X reduction telescope fit the pump light to the OPO cavity’s 335 μm 1/e2 mode radius. Two separate experiments using 7 and 100 ns pulses were run to achieve the highest mid-IR peak power and pulse energy, respectively. A peak power of 28 kW (165 μJ energy) for 7 ns pump pulses and a pulse energy of 280 μJ for 100 ns pulses were achieved.

Wavelength tuning of the OPO for signal and idler were demonstrated over a 3.3 to 4.7 μm wavelength range; good performance at longer wavelengths could be achieved with the use of optimized mirrors, say the researchers.

REFERENCE

1. M. Gebhardt et al., Opt. Lett. (2014); http://dx.doi.org/10.1364/OL.39.001212.

John Wallace | Senior Technical Editor (1998-2022)

John Wallace was with Laser Focus World for nearly 25 years, retiring in late June 2022. He obtained a bachelor's degree in mechanical engineering and physics at Rutgers University and a master's in optical engineering at the University of Rochester. Before becoming an editor, John worked as an engineer at RCA, Exxon, Eastman Kodak, and GCA Corporation.