Pumped with blue light, Holmium-doped fluoride laser emits in the green

New laser gain materials are always a good thing: for one, if they are made practical and work well enough, they can potentially improve on existing laser types. Even if the materials don’t lead to practical devices, they may be a stimulus for further research into other new gain materials. Now, a group of scientists from the Institute of Laser-Physics, the Center for Free-Electron Laser Science at DESY, and the Hamburg Centre for Ultrafast Imaging (all in Hamburg, Germany) and Università di Pisa (Italy) has developed a green-emitting laser based on doping by the rare-earth metal holmium (Ho), in the form of a doped lithium lutetium fluoride (Ho3+:LiLuF4) crystal. Pumped by a blue laser diode, the room-temperature pulsed laser emitted at a 549.4 nm wavelength with average output power of 7.7 mW, a pulse-repetition rate of 5.3 kHz, and a pulse duration of 1.6 μs.

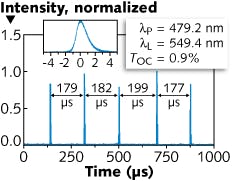

The hemispherical laser resonator consisted of a plane input coupling mirror and a spherical output mirror with a 50 mm radius of curvature. The input mirror transmitted the 486.2 nm pump wavelength and was highly reflective in the green region. Single-pass absorption at the (nonoptimized) pump wavelength was estimated to be 3% to 4%; the output coupling rate (TOC) was about 0.9%. Output pulses occurred roughly every 180 to 200 μs. The research also tried to get a Ho-doped lanthanum fluoride (Ho3+:LaF3) crystal to lase when pumped with blue light, without success. However, in a quick qualitative experiment, they did get the material to lase when pumped by a frequency-doubled diode-pumped solid-state laser emitting at 532 nm. Reference: F. Reichert et al., Opt. Mater. Express 5(1), (2015); http://dx.doi.org/10.1364/OME.5.000088.